Features of large scale rotary evaporator:

D-RE-1002 D-RE-2002 D-RE-5002 rotary evaporator is a rotary evaporator independently researched and developed by our company. It has two condensers, a main and a secondary condenser, and two receiving bottles. It can be customized, and the price is cheap. Simple, stable in quality, economical and practical, it is an important equipment for separation, crystallization, drying, purification, recycling and other operations in the fields of biopharmaceuticals, medicine, chemistry and chemical engineering.

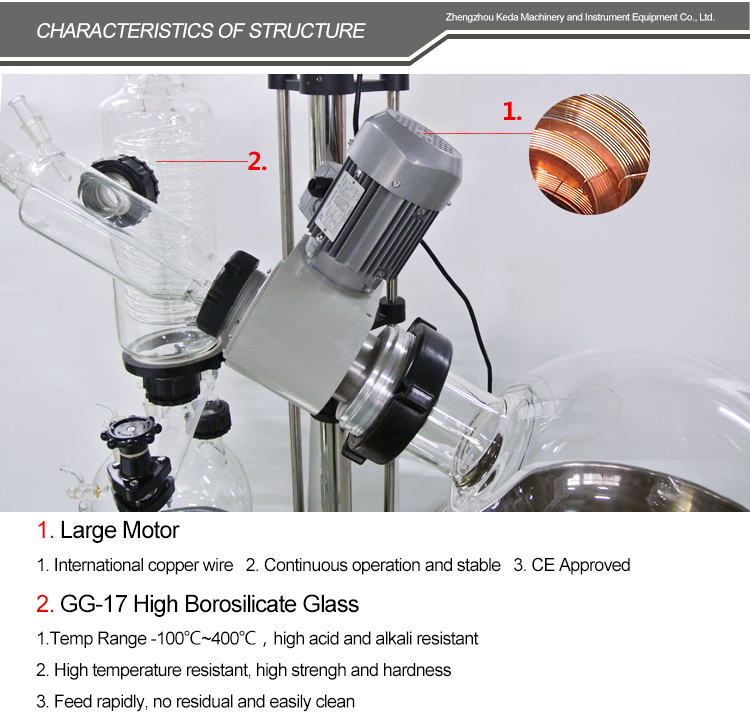

Advantages of large scale rotary evaporator:

1. ce, iso certified product patent certificate

2. Manual lifting, high stability, knob button adjustment, digital display, convenient operation.

3. The main and auxiliary double condensers, the design of double receiving bottles, the material recovery rate is high, and it is convenient for more materials to be distilled and recovered and condensed.

4. The bracket is made of 304 stainless steel, which is strong and durable. The rotating bottle, receiving bottle and condenser are made of high-quality high-quality borosilicate glass, which is heat-resistant and shock-resistant, and is not easy to break.

5. The main engine starts stably, the speed is 0-120 (r/m), the motor and circuit adopt imported products, and can be upgraded to explosion-proof, safer and longer service life.

6. The sealing part adopts the principle of flange sealing, which can maintain high vacuum.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technicians put forward reasonable suggestions based on the use of the product, and assist the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

D-RE-1002: DLSB-20/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

D-RE-2002: DLSB-30/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

D-RE-5002: DLSB-50/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

FAQ:

What is the working principle of a rotary evaporator?

It is heated under constant temperature and rotated under negative pressure to form a thin film, and at the same time the solvent is evaporated and condensed for recovery. It is especially suitable for concentration, crystallization, separation and recovery of heat-sensitive materials.

The supporting equipment of the rotary evaporator to heat the water bath:

The general heating medium for heating the water bath is clean water. If there is a special need for temperature, it can be replaced with silicone oil or high-temperature silicone oil. Close the lid in time to prevent dust from entering the water bath or oil bath and keep the water bath or oil bath clean.

The condenser of the rotary evaporator:

Condenser: The general cooling medium is water. If the ambient temperature is high and the condensation effect is not good, it can be replaced with ethanol and equipped with a circulating refrigerator. The ethanol after cooling is pressed into the condenser for cooling treatment. In cold weather, when the condenser is not in use, the water in the condenser should be drained overnight to prevent the water from solidifying, expanding in volume, and bursting the condenser.

Model | D-RE-1002 | D-RE-2002 | D-RE-5002 |

Evaporating Flask(L) | 10 | 20 | 50 |

Receiving Flask(L) | 5 | 10 | 20 |

Rotating Motor(W) | 180W | ||

Rotating Speed(R/MIN) | 0-120 | 0-120 | 0-90 |

Water(Oil) Bath Power(W) | 3000 | 4500 | 7000 |

Temperature Control Range | RT-399℃ | ||

Temperature Fluctuation(℃) | ±1℃

| ||

Evaporation Rate(H2O) | >3L/h | ≥5L/h | ≥9L/h |

Condenser | Double main condenser, One vice condenser | ||

Lifting Mode | Water(Oil) Bath Mannal Lifting | ||

Lifing Height(mm) | 0~220 | ||

Voltage | 220V50HZ | 220V/50HZ | 380V50HZ |

Sealing Mode | PTFE,Fluoro Rubber Sealing | ||

Note | Customized configuration is available | ||