Features of digital rotary evaporator:

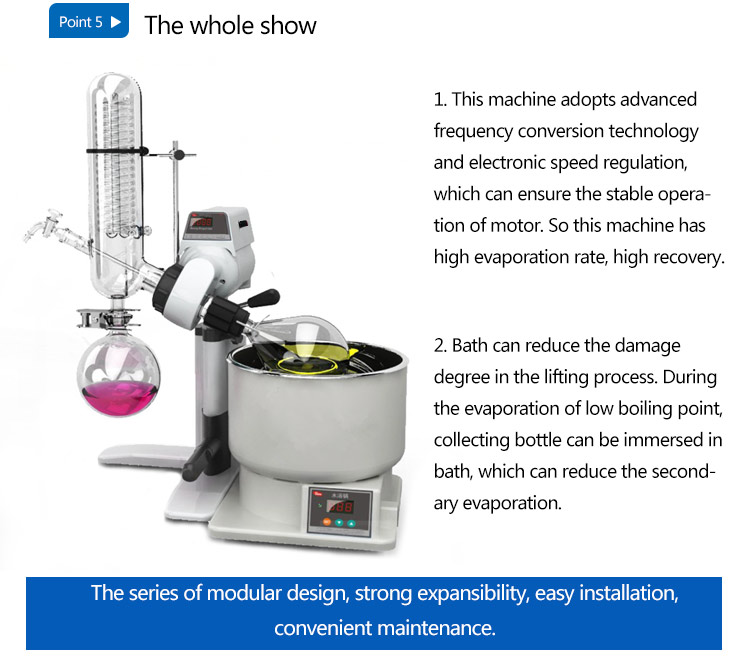

N-1100D digital rotary evaporator is a small volume rotary evaporator sold directly by our company, also called micro rotary evaporator. It is cheap, simple to operate, stable in quality, economical and practical. It is used for separation and crystallization in biopharmaceutical, pharmaceutical, chemical and chemical fields. , Drying, purification, recycling and other important equipment for operations.

Advantages of digital rotary evaporator:

1. ce, iso certified product patent certificate.

2. The rotating bottle can be raised and lowered manually or electrically, with knob button adjustment and digital display, making the operation more convenient.

3. Rotating bottle 0.5-2L, receiving bottle 1L, small capacity, suitable for vacuum distillation extraction of small materials.

4. The weight is only 9.5kg, the volume is small and does not take up space.

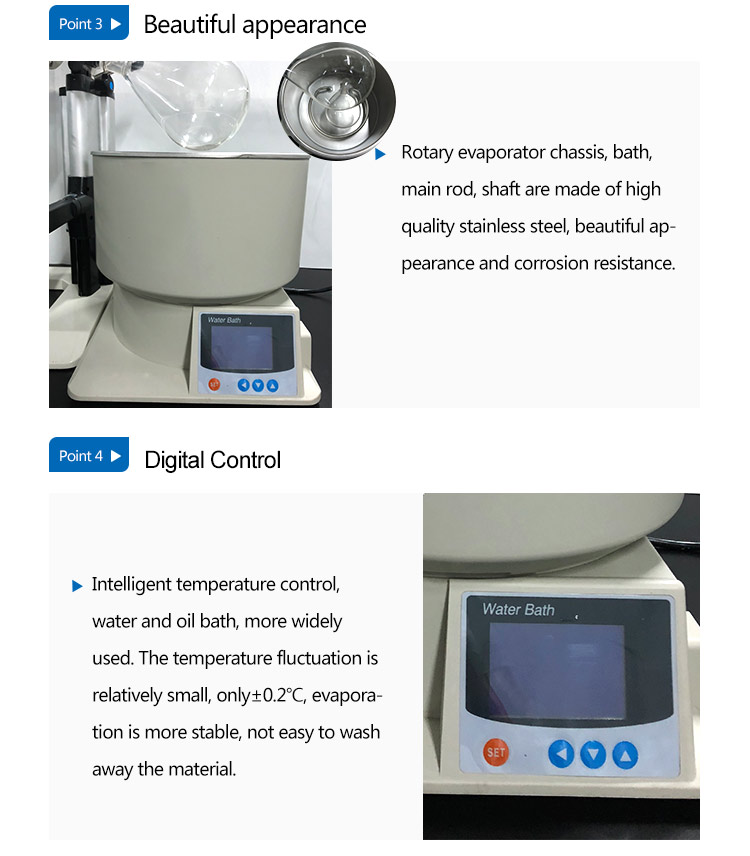

5. The bracket is made of 304 stainless steel, which is strong and durable. The rotating bottle, receiving bottle and condenser are made of high-quality high-quality borosilicate glass, which is not easy to break.

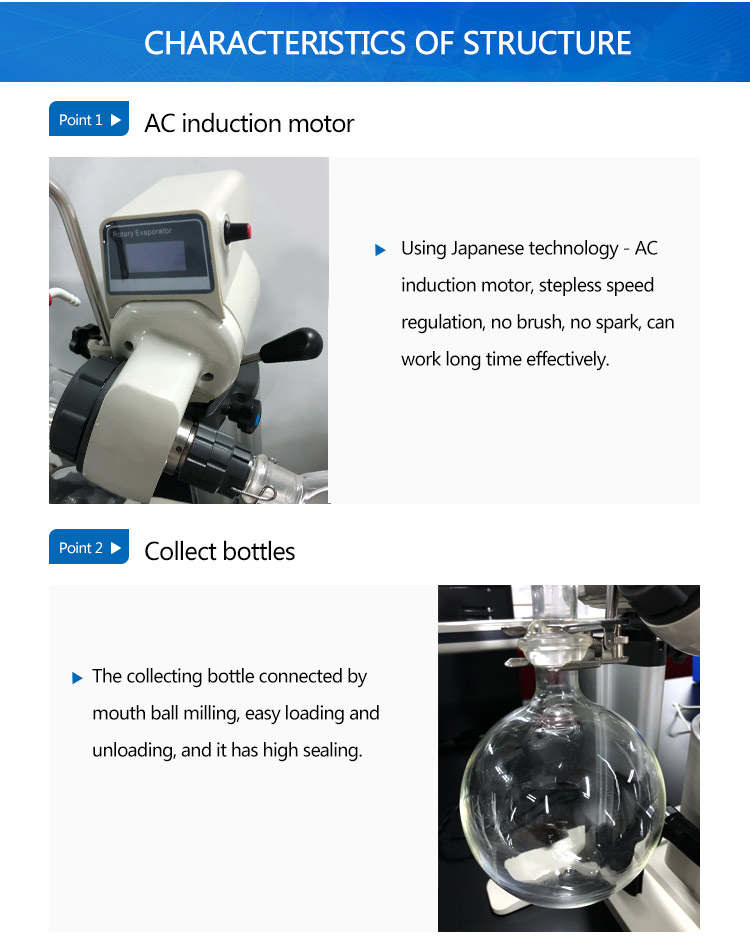

6. The motor and circuit adopt imported products, and can be upgraded to explosion-proof, safer and longer service life.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technicians put forward reasonable suggestions based on the use of the product, and assist the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

N-1100D: DLSB-5/10 low-temperature coolant circulating pump and SHZ-D (Ⅲ) circulating water vacuum pump

FAQ:

What are the precautions for digital rotary evaporators?

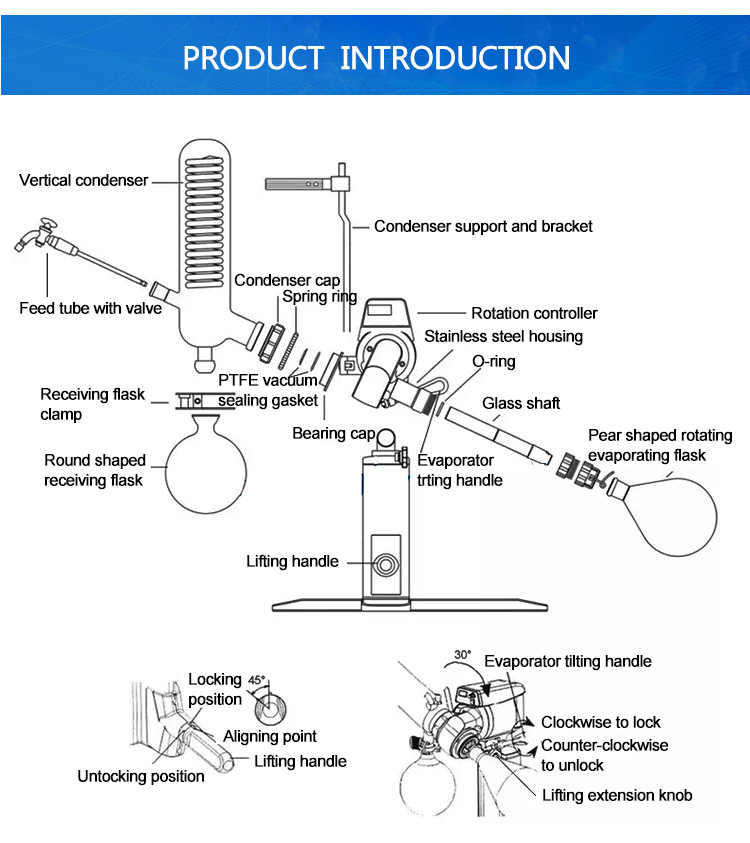

1. If the vacuum cannot be drawn up, check: whether the joints and interfaces are sealed; whether the sealing ring and the sealing surface are effective. Whether the vacuum grease is applied between the main shaft and the sealing ring; whether the vacuum pump and its hose are leaking; whether the glass parts are cracked, broken, or damaged.

2. A layer of vacuum grease must be applied to each grinding port, sealing surface sealing ring and joints before installation.

3. Water must be added before the heating tank is energized, and dry heating without water is not allowed.

4. Screw into the safety hole to prevent damage to the flask.

5. The assembly of glass parts should be handled with care, and should be washed, wiped dry or dried before assembly.

What is the difference between a digital rotary evaporator and ordinary distillation?

Rotary evaporator and ordinary distillation have different distillation speeds

When the rotary evaporator distills, because the evaporation surface area of the solution is large, the evaporation speed is fast.

Ordinary distillation can not evaporate a large area, so the evaporation rate is relatively slow.

Decompression vacuum equipment of digital rotary evaporator?

Decompression equipment: often configured as a water pump. For some solvents with high boiling points, the water pump can be replaced with an oil pump. Pay attention to the requirements of the equipment when replacing it.

What is the scope of application of the digital rotary evaporator?

The rotary evaporator uses a rotary evaporator bottle to increase the evaporation area and place it in a water bath under reduced pressure while rotating while heating the device to diffuse and evaporate the solution in the bottle. It is an ideal and necessary basic instrument for manufacturing and analysis experiments in the chemical industry, pharmaceutical industry, universities and scientific research laboratories, such as concentration, drying, and recycling.

Model | N-1100-D |

Rotary speed(Rpm) | 10~180 |

Evaporating speed(ml/min) | 20 |

Achievable vacuum(Pa) | 399.9 (below 3mmHg) |

Temperature range(℃) | Room temp~100 |

Temperature display | Keypad input Digital display |

Speed-setting | Knob setting ,Digital display |

Safety functions | Fuse |

Functions of lifting table | Weight balancing Gliding elevating+ manual lifting |

Rotary motor(W) | 25 |

Heater wattage(KW) | 1.5 |

Condenser model | Lean type water refrigerating |

Rotary bottle(L) | 0.5~1 |

Collecting bottle(L) | 1 |

Vacuum sealing | Double sealing rings made of Teflon+ Vinton materials |

Water Bath size and volume(L) | φ260×140·7.4 |

Elevating stroke(mm) | 100+150 |

Ambient temperature(℃) | 5~35 |

Dimensions (mm) | 750L×320W×540H |

Weight(kg) | 9.5 |

Power Supply(V/Hz) | 220/50 |