Features of 10L 20L 50L rotovaps:

RE-1002 RE-2002 RE-5002 rotovaps are rotovaps independently researched and developed by our company. It has a main and auxiliary condenser, which can be customized. It is cheap, simple to operate, stable in quality, economical and practical. It is a biopharmaceutical It is an important equipment for separation, crystallization, drying, purification, recycling and other operations in the fields of, medicine, chemistry and chemical engineering.

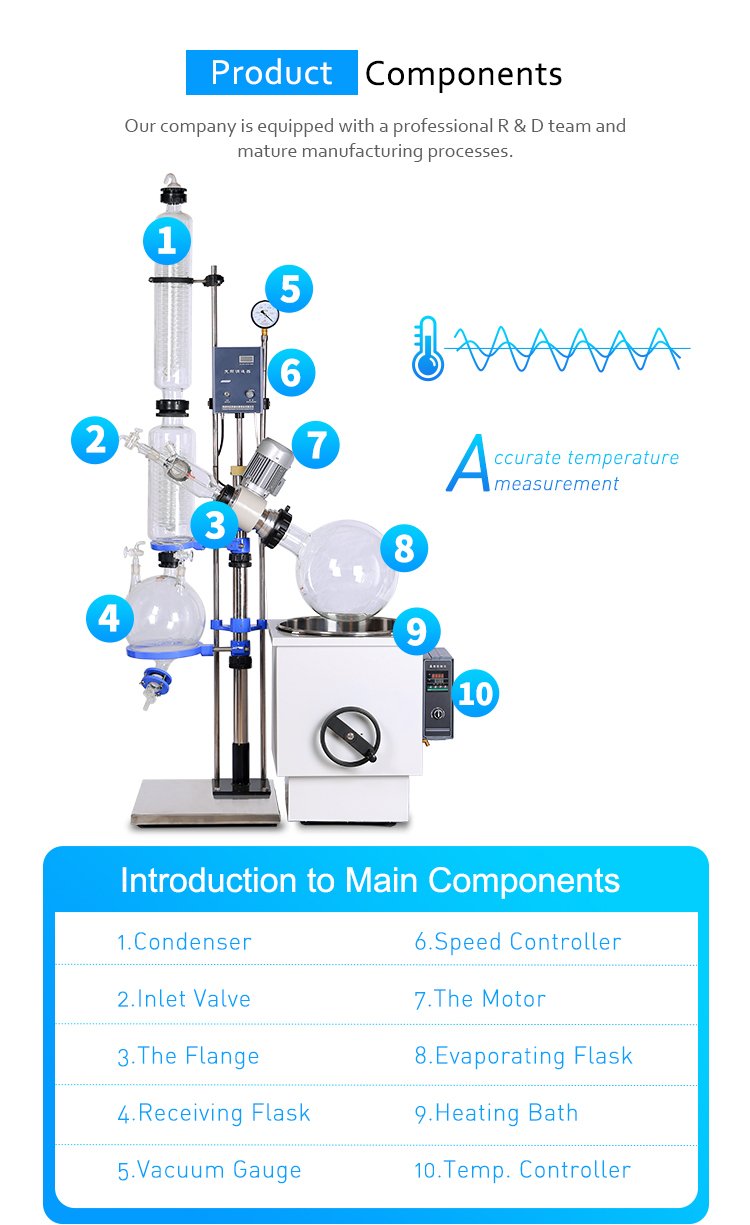

Advantages of 10L 20L 50L rotovaps:

1. ce, iso certified product patent certificate

2. Manual lifting, high stability, knob button adjustment, digital display, convenient operation.

3. The main and auxiliary double condenser design, the material recovery rate is high, the recovery rate can reach 95%.

4. The bracket is made of 304 stainless steel, which is strong and durable. The rotating bottle, receiving bottle and condenser are made of high-quality high-quality borosilicate glass, which is not easy to break.

5. The rotating host starts stably, the speed is 0-120 (r/m), the motor and circuit adopt imported products, and can be upgraded to explosion-proof, safer and longer service life.

6. The sealing part adopts the principle of flange sealing, which can maintain high vacuum.

Advantages of 10L 20L 50L rotovaps:

1. ce, iso certified product patent certificate

2. Manual lifting, high stability, knob button adjustment, digital display, convenient operation.

3. The main and auxiliary double condenser design, the material recovery rate is high, the recovery rate can reach 95%.

4. The bracket is made of 304 stainless steel, which is strong and durable. The rotating bottle, receiving bottle and condenser are made of high-quality high-quality borosilicate glass, which is not easy to break.

5. The rotating host starts stably, the speed is 0-120 (r/m), the motor and circuit adopt imported products, and can be upgraded to explosion-proof, safer and longer service life.

6. The sealing part adopts the principle of flange sealing, which can maintain high vacuum.

Grouped equipment:

RE-1002: DLSB-20/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

RE-2002: DLSB-30/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

RE-5002: DLSB-50/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

FAQ:

What is the difference between a rotovap and ordinary distillation?

Rotovap and ordinary distillation have different uses

10L 20L 50L rotovaps are generally used for extraction and concentration of CBD, medicines, chemistry, and laboratories, so that materials can be distilled and extracted in a closed vacuum environment.

Ordinary distillation is generally used for the drying treatment of easily decomposable materials.

What should I do if the vacuum of the 10L 20L 50L rotovaps cannot be pumped?

It is possible that there is solvent in the container and is limited by the saturated ejector pressure. The solvent needs to be emptied and the bottle is empty and try again; the capacity of the vacuum oil pump is reduced, the oil (water) needs to be changed, and the vacuum oil pump is cleaned and repaired; the vacuum hose joint is loose , Vacuum meter leaks, it needs to be tested and eliminated step by step along the vacuum pipeline; if there are debris in the discharge valve and pressure control valve, clean it; if the glass wool sandwich panel is damaged, it can be updated or repaired.

Why choose high borosilicate glass for the glass part of the 10L 20L 50L rotovaps?

Our company's rotary evaporators all use high borosilicate glass, because it is acid and alkali resistant, high temperature resistant, high transparency, wear resistant, smooth surface and easy to clean.

How to choose the supporting equipment of the 10L 20L 50L rotovaps?

We suggest to choose low-temperature coolant circulation pump, circulating water vacuum pump, you can also contact us, we will make suggestions according to your needs.

Model | RE-1002 | RE-2002 | RE-5002 |

Evaporating Flask(L) | 10 | 20 | 50 |

Receiving Flask(L) | 5 | 10 | 20 |

Rotating Motor(W) | 180W | ||

Rotating Speed(R/MIN) | 0-120 | 0-120 | 0-90 |

Water(Oil) Bath Power(W) | 3000 | 4500 | 7000 |

Temperature Control Range | RT-399℃ | ||

Temperature Fluctuation(℃) | ±1℃

| ||

Evaporation Rate(H2O) | >3L/h | ≥5L/h | ≥9L/h |

Condenser | Vertical Double Condenser | ||

Lifting Mode | Water(Oil) Bath Mannal Lifting | ||

Lifing Height(mm) | 0~220 | ||

Voltage | 220V50HZ | 220V/50HZ | 380V50HZ |

Sealing Mode | PTFE,Fluoro Rubber Sealing | ||

Note | Customized configuration is available | ||