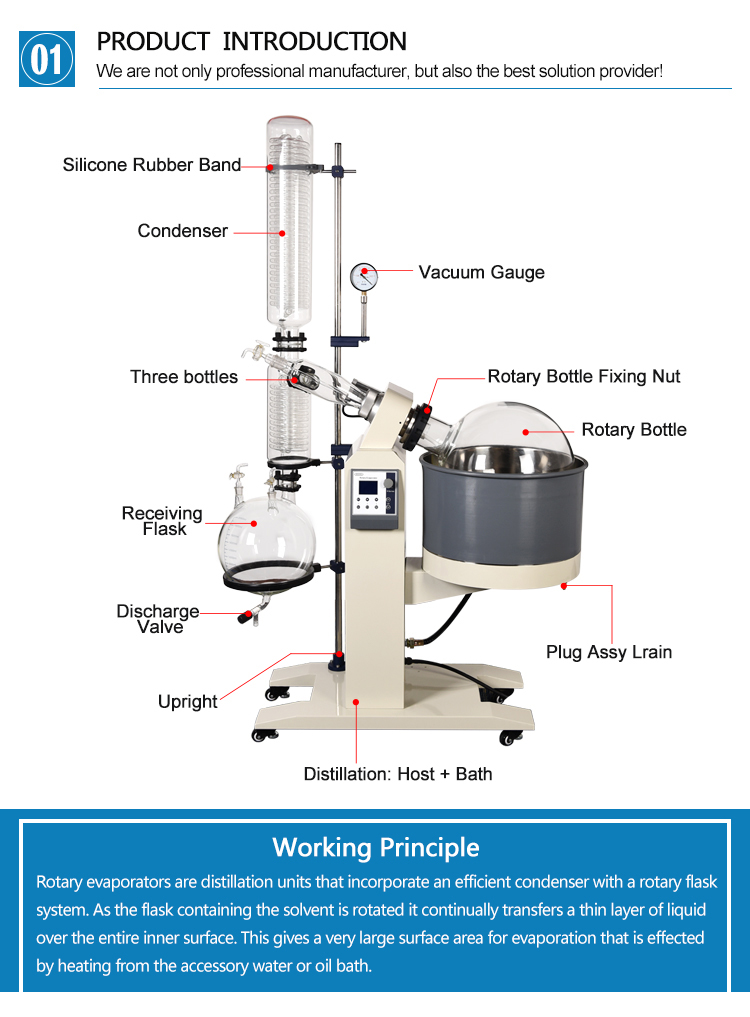

Features of 5L 10L 20L 50L rotary evaporator:

R-1005 R-1010 R-1020 R-1050 rotary evaporator are rotary evaporators independently developed by our company. The volume of the rotary bottle is 5L, 10l, 20l, 50l. The capacity can be customized, the price is cheap, the operation is simple, and the quality is stable. It is economical and practical. It is an important equipment for separation, crystallization, drying, purification and other operations in biopharmaceutical, pharmaceutical, chemical and chemical industries.

Advantages of 5L 10L 20L 50L rotary evaporator:

1. ce, iso certified product patent certificate.

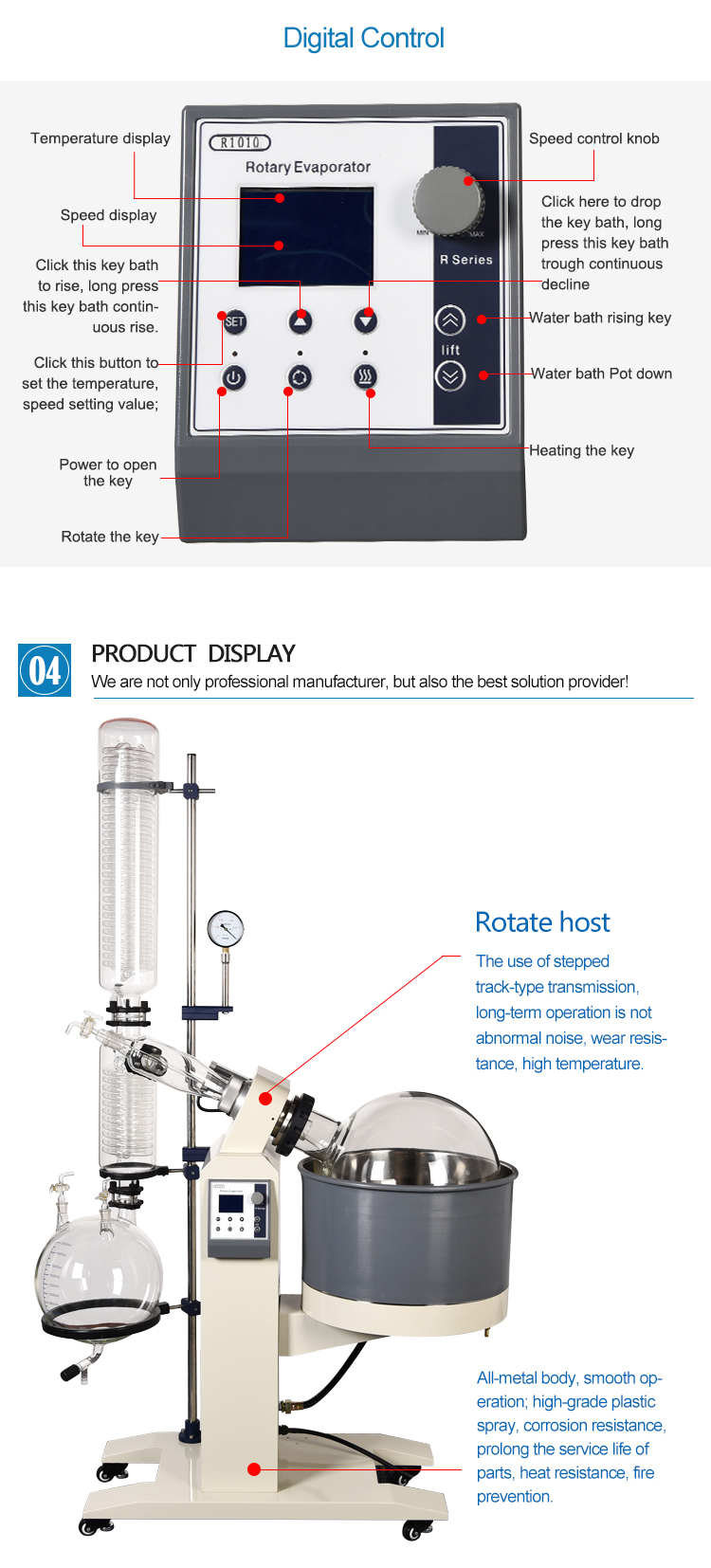

2. Electric lifting, rotating button adjustment, digital display, convenient operation.

3. The motor adopts international copper wire, which has a long continuous running time and good stability.

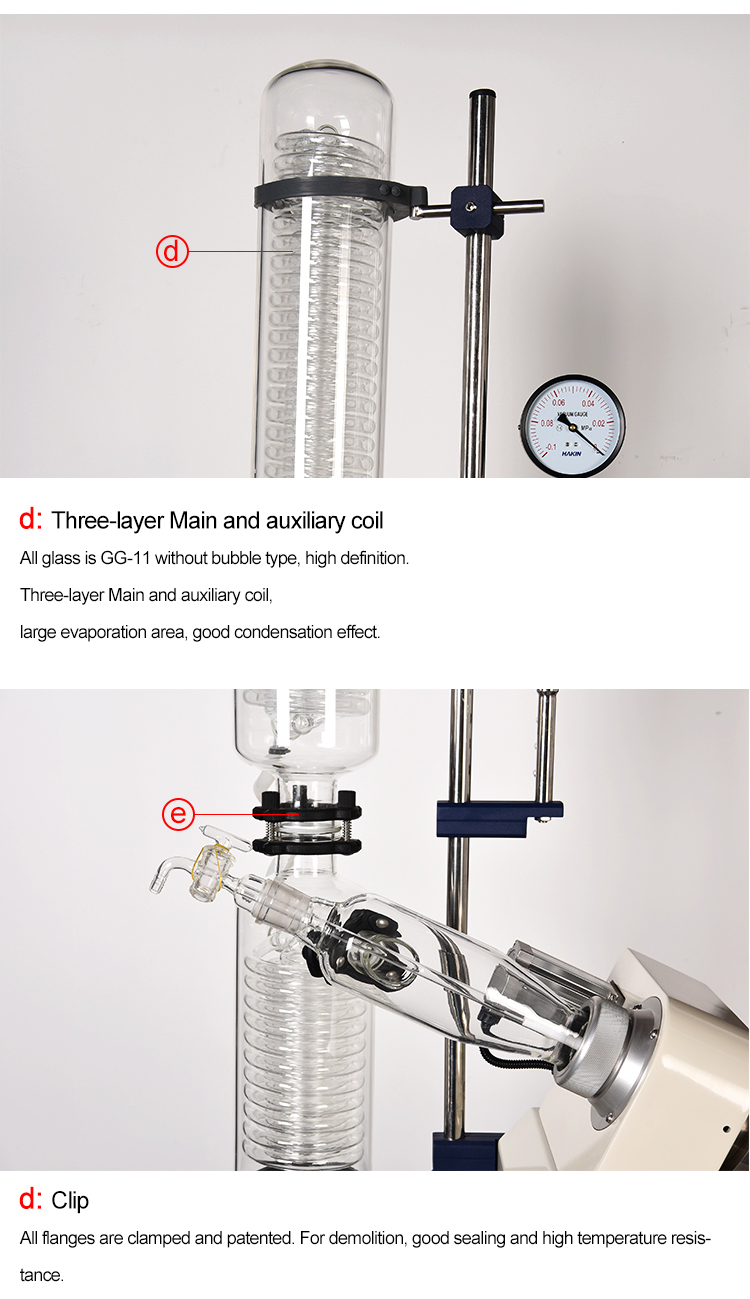

4. The sealing part adopts the principle of flange sealing, which can maintain high vacuum.

5. This type of rotary evaporator uses high-quality high-quality borosilicate glass, heat-resistant and shock-resistant, not easy to break.

6.1°c-100°c temperature adjustment, 0-120 (r/m) speed adjustment, to meet various needs of laboratory instruments.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technicians put forward reasonable suggestions based on the use of the product, and assist the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

R-1005 5L rotary evaporator: DLSB-20/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

R-1010 10L rotary evaporator: DLSB-20/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

R-1020 20L rotary evaporator: DLSB-30/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

R-1050 50L rotary evaporator: DLSB-50/30 low-temperature coolant circulating pump and SHZ-C circulating water vacuum pump

FAQ:

What should I do if the power indicator does not light up after the rotary evaporator is switched on?

If the power cord is not connected or connected incorrectly, just connect the power cord; if the power switch or circuit board fails, stop using it immediately and contact the manufacturer or professional maintenance personnel.

What should I do if the motor of the rotary evaporator does not rotate?

If the indicator light of the electric control box is on, check whether the connection between the internal and external plugs in the electric box is loose or disconnected, re-plug the plug and connect the broken wire; if the indicator or digital display of the electric control box does not light up, update the fuse or confirm There is no abnormality in the power supply; if the inverter displays "OU" due to high frequency interference, just troubleshoot the fault according to the inverter manual.

What is the conventional vacuum degree of the rotary evaporator?

The maximum vacuum is 399.9 (below 3mmHg).

What material is generally used for the rotary evaporator water bath (oil bath)?

Our company's rotary evaporator is generally made of stainless steel with a protective cover, which is corrosion-resistant, heat-resistant, and not easy to rust.

Mode | R1005 | R1010 | R1020 | R1050 |

Optimum ambient temperature℃ | 5~35 | |||

Working power supply (V/Hz) | Single phase 220/60 | Three phase 220-240V/380v/60Hz | ||

Main engine speed control | Digital frequency conversion stepless speed regulation | Digital direct current stepless speed | ||

Main engine speed (RPM) | 10~140 | 20~130 | 20~110 | |

Rotary electric machine (W) | 40 | Brushless 250 | ||

Temperature control (℃) | Digital display temperature control,room temperature -99 | |||

Maximum vacuum (Pa) | 399.9(Below 3mmHg) | |||

Rotating bottle (L) | Five | Ten | Twenty | Fifty |

Flange size | Flange 50 | Flange 125 | Flange 125 | Flange 125 |

Recovery bottle (L) | 3 | 5 | 10 | 20 |

Condenser tube | Vertical double coil | Vertical main cold+cold side, high effeciency reflux condenser | ||

Evaporation capacity (L/h) | The water is more than 2 | The water is more than 3. 2 | The water is more than 5 | The water is more than 9 |

Water bath pot material | Stainless steel | |||

Water bath pot size (mm) | Φ300×170 | Φ350×220 | Φ450×260 | Φ550×320 |

Lifting function | Electric lift | Electric + hand lift | ||

Lift stick (mm) | 0~150 | 0~160 | 0~190 | 0~180 |

Whole power (KW) | 2 | 3 | 4 | 4.0(220-240V) |

Outline dimension (mm) | 7650×400×1070 | 920×550×1700 | 1250×600×2100 | 1320×770×2340 |