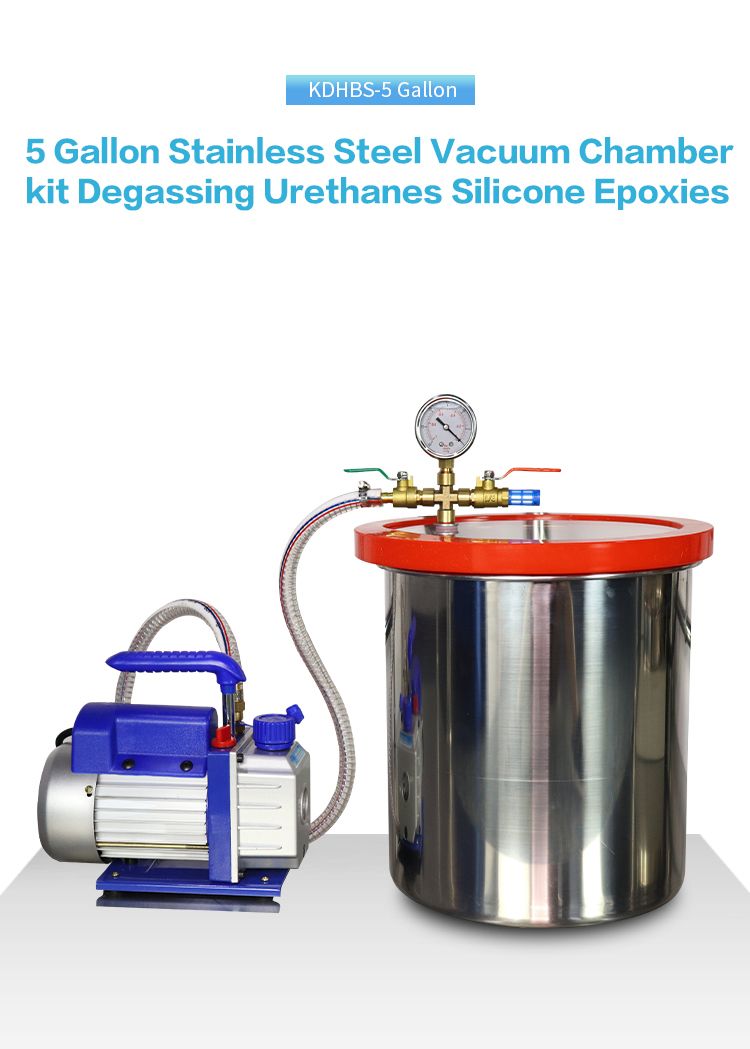

The vacuum chamber is very suitable for removing gases from the compounds remaining in the mixture when the components are mixed. When mixing resin and silicone rubber and slow-solidifying resin, a vacuum chamber is required to ensure a bubble-free mold. Our vacuum chamber greatly reduces bubbles and bubbles that can weaken epoxy or silicone resin. The transparent lid allows you to see the air drawn from the resin mixture. Built-in valve and pressure gauge provide ease of use and convenience.

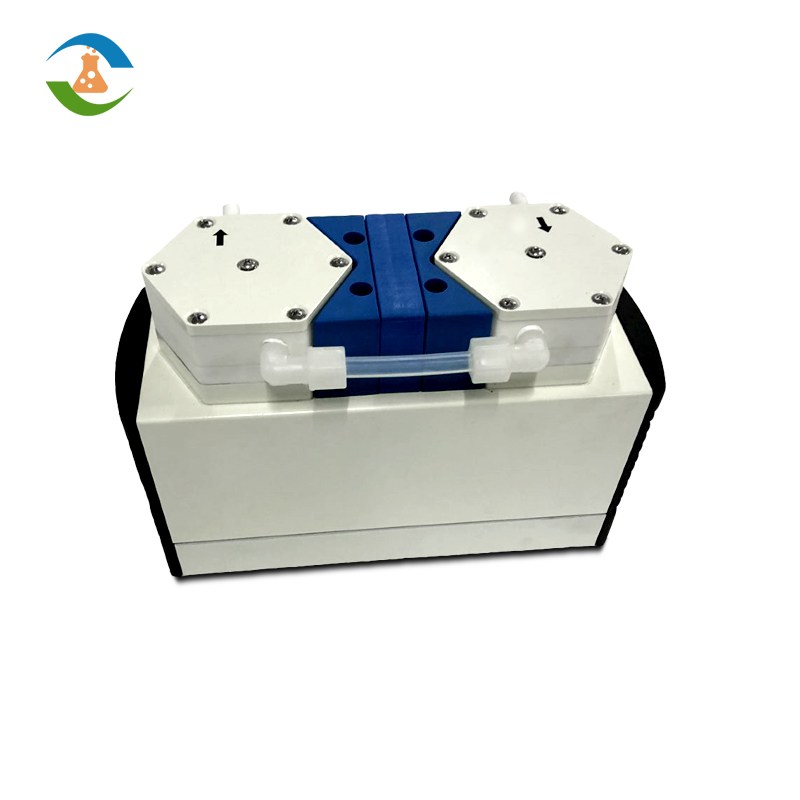

Advantages of stainless steel vacuum chamber:

The stainless steel vacuum chamber is stirred while being evacuated, so that the raw materials are degassed faster, and the mixing and mixing of materials is more complete. Can be used for: resin, paint, ink, pigment, PVC raw material, silica gel, battery colloid, adhesive, dispersant, gypsum, red glue, silicone paint, etc.

Features of stainless steel vacuum chamber:

1. Small and exquisite appearance.

2. All stainless steel material.

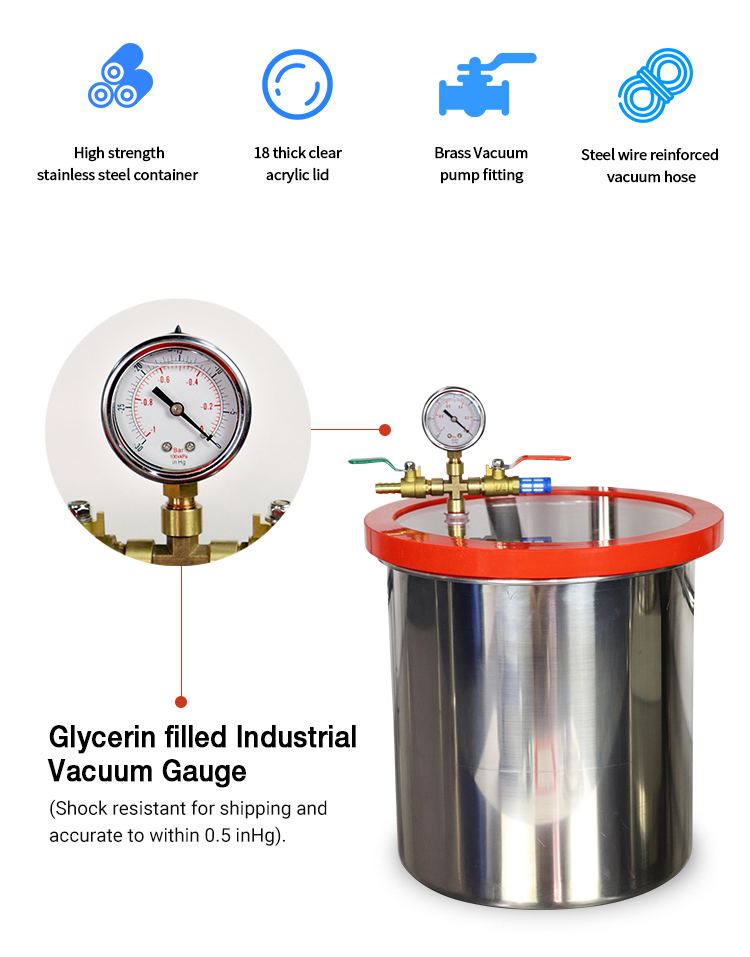

3. Large windows, all specifications use 18mm thick plexiglass, absolutely no deformation.

4. Silicone sealing ring, high air tightness, high vacuum retention, longer life.

5. Super thick material, high safety (strong compressive ability, never deformed).

6. Vibration-resistant vacuum gauge (oil flushing in the vacuum gauge).

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technicians put forward reasonable suggestions based on the use of the product, and assist the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

1. What are the models of your stainless steel vacuum chamber?

RS-1 (+2 Gallon bucket), RS-2 (+ 3 Gallon bucket), RS-4 (+5 Gallon bucket), 2RS-4 (+ 6 Gallon bucket), etc.

2. What are the supporting equipment of the stainless steel vacuum chamber?

Small vacuum pump.

3. What is the working principle of a stainless steel vacuum chamber?

The stainless steel vacuum chamber is an economical alternative to the traditional vacuum drying oven. The vacuum chamber, together with a silicone heating pad or oil/water heating tank, can gently dry the sample without residue, scaling or oxidation. In the absence of a heat source, the vacuum chamber can also be an ideal tool for silicone/resin degassing and vacuum storage.

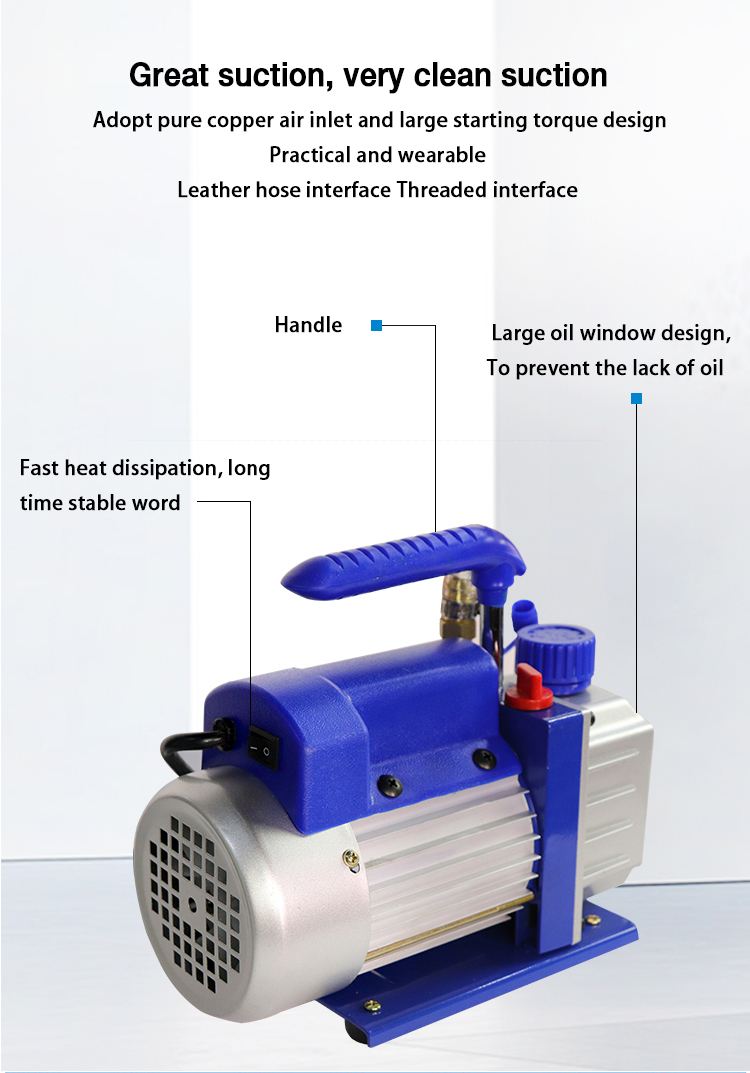

MODEL | RS-1 | RS-2 | RS-4 | 2RS-4 |

voltage (V/Hz) | 220/50 110/60 | |||

Pumping rate (CFM) | 2.5(220V)3.0(110V) | 4.5(220V)5.0(110v)8.0(220v)9.0(110V) | 10(220V)12(110V) | |

.Ult.Vacuum (PA) | 5 | 5 | 5 | 0.2 |

Motor power (HP) | 1/4 | 1/3 | 3/4 | 1 |

Oil capacity (mL) | 220 | 250 | 300 | 550 |

Dimensions (mm) | 260*110*240 | 290*120*240 | 360*135*270 | 430*142*280 |

Barrel inner diameter (cm) | 22*20 | 22*29 | 28*29 | 28*39 |

weight(kg) | 10 | 13 | 18 | 25 |