Advantages of diaphragm vacuum pumps:

It provides vacuum conditions for evaporation, distillation, crystallization, drying, sublimation, filtration, decompression, and degassing, and is suitable for solvent recovery, various highly toxic, flammable and explosive, strong acid, strong alkali extraction, etc.

Features of diaphragm vacuum pump:

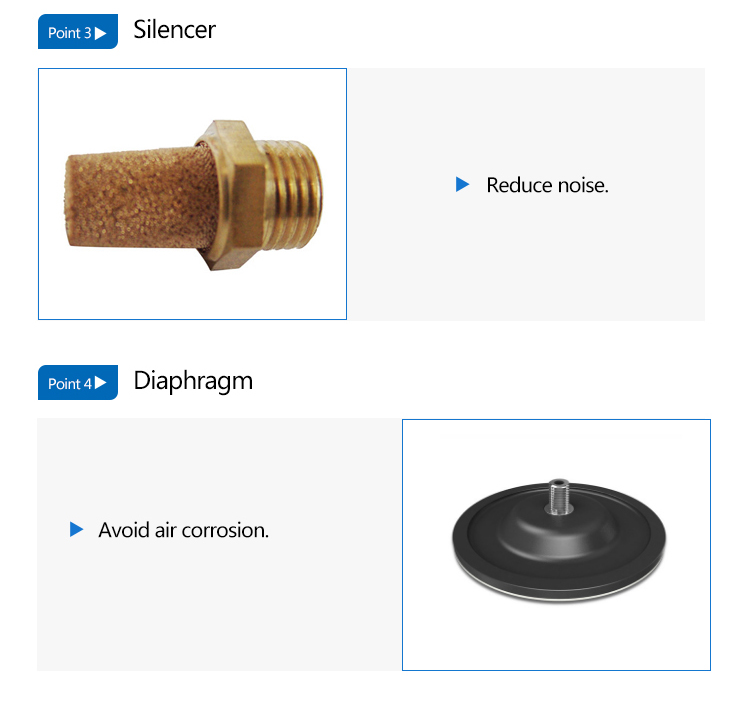

1. No need for any working medium (no oil), no pollution, at the same time, the gas exchange chamber of the machine is built with filter materials, thus ensuring the purity of the air.

2. No need for any working medium, no friction at the working part.

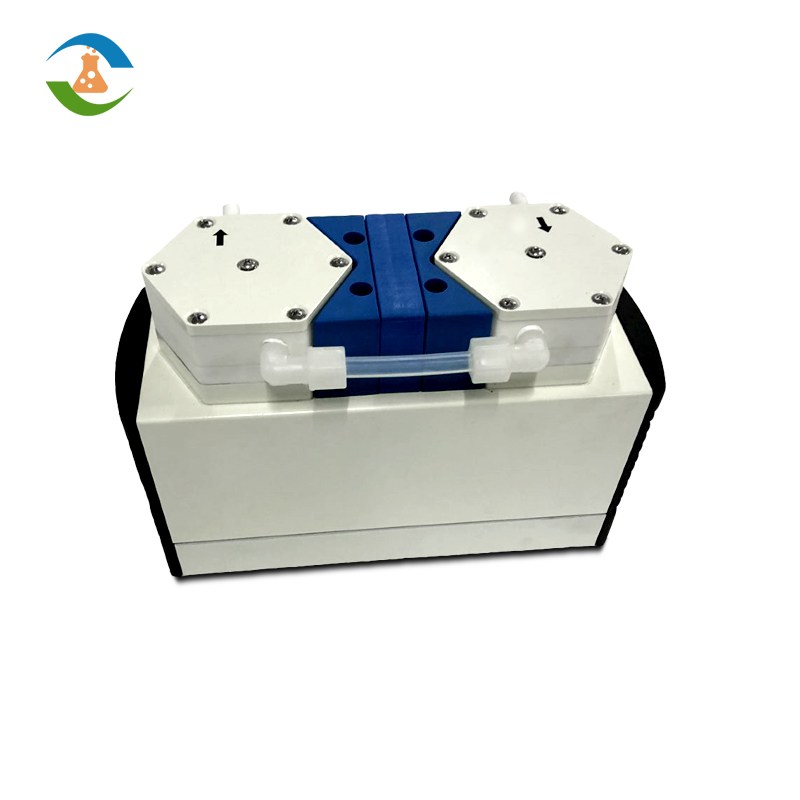

3. Small size, light weight, easy to move and save space.

4. The air inlet separation bottle can prevent solid particles and liquid water from entering the pump body.

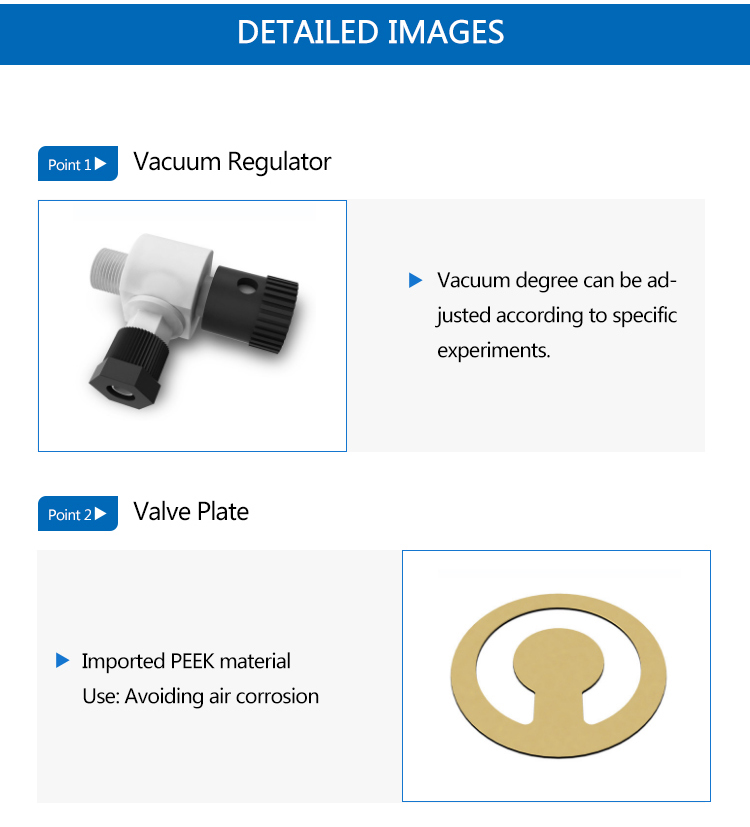

5. Imported PEEK material valve plate and Teflon material diaphragm are used to effectively prevent gas corrosion.

6. Convenient maintenance and repair.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

1. The structure of the diaphragm pump

Diaphragm pump is mainly composed of transmission part and diaphragm cylinder head. The transmission part is a driving mechanism that drives the diaphragm to agitate back and forth. Its transmission forms include mechanical transmission, hydraulic transmission and pneumatic transmission. Among them, hydraulic transmission is widely used. The working part of the diaphragm pump is mainly composed of the crank connecting rod mechanism, the plunger, the hydraulic cylinder, the diaphragm, the pump body, the suction valve and the discharge valve, etc., among which the driving mechanism and the reciprocating plunger composed of the crankshaft connecting rod, the plunger and the hydraulic cylinder The pumps are very similar.

2. What should I pay attention to when using a diaphragm vacuum pump?

Diaphragm vacuum pumps should be placed as close to the supporting products as possible, and at the same time, the pumps should be placed as close as possible to the pumped liquid. When the inlet pressure exceeds 10 feet (3 meters) of liquid column, a slow pressure regulator is required to extend the life of the diaphragm. If the equipment is a hard pipe, use a short hose to connect the pump and the pipe. The hose can slow down the vibration and distortion of the pipeline. It is recommended to use a pressure stabilization tank to further reduce pulses in the fluid.

3. How to install the diaphragm vacuum pump?

The best installation should be at the connection of the shortest and straightest inlet and outlet pipelines. Should try to avoid additional elbows and pipe fittings. The pump body should be able to independently support all pipelines. Moreover, the piping should be arranged in an orderly manner to avoid stress on the pump body piping device.

Model | DP401 |

Power(W) | 250 W |

Power supply(V/Hz) | 220/50 |

Speed(rpm) | 1400 |

Inspiratory diameter (mm) | ф10 |

Exhaust diameter (mm) | ф10 |

Maximum vacuum (DPA) | 0.098(20mbar) |

Pumping capacity (L / min) | 45 |

Overall dimension (mm) | 195L×440W×290H |

Weight (kg) | 15 |