Advantages of diaphragm vacuum pumps:

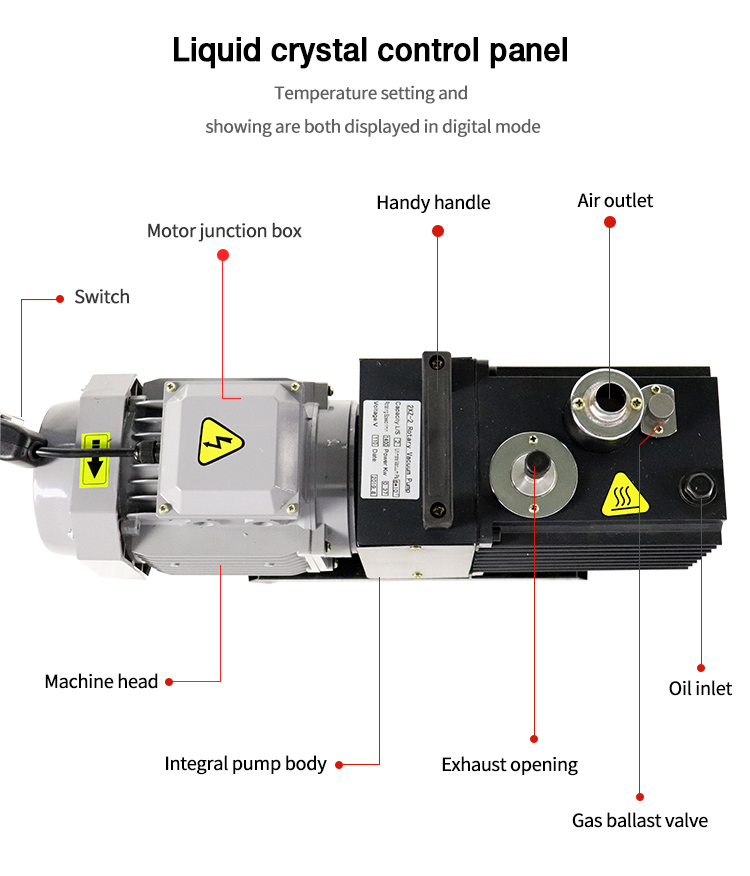

The 2XZ series rotary vane vacuum pump can be used alone or as a backing pump for booster pumps, diffusion pumps, molecular pumps and titanium pumps. Used in electronic device manufacturing, vacuum drying, filtration, welding, metal smelting and other fields.

Features of diaphragm vacuum pump:

1. Super strong ability to remove water vapor.

2. The export oil mist filter is a standard configuration, and the rotary vane pump oil is recycled, no oily smoke, clean, environmentally friendly, and fuel-efficient.

3. It can work continuously when the inlet pressure is atmospheric pressure.

4. High pumping speed can still be maintained under low pressure.

5. Built-in automatic anti-return valve.

6. Air cooling, water cooling is not needed, economical and convenient

7. Low noise and low vibration.

8. Compact structure, small size and space saving.

9. It can be used with various accessories, so it can meet the needs of various applications.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technicians put forward reasonable suggestions based on the use of the product, and assist the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

Is the noise of the rotary vane vacuum pump loud? How many decibels are there?

The noise is very small, below 60 decibels.

What are the environmental requirements of rotary vane vacuum pumps?

The best working temperature is in the range of 20~25℃.

What are the application ranges of rotary vane vacuum pumps?

It can be widely used in vacuum smelting, vacuum welding, vacuum heat treatment, vacuum drying, vacuum packaging and other processes in metallurgy, medicine, chemical industry, printing machinery, packaging machines and other industries. It can be used as a front pump for diffusion pumps, molecular pumps, etc., for electronic instruments, medical instruments and other supporting and experimental research applications.

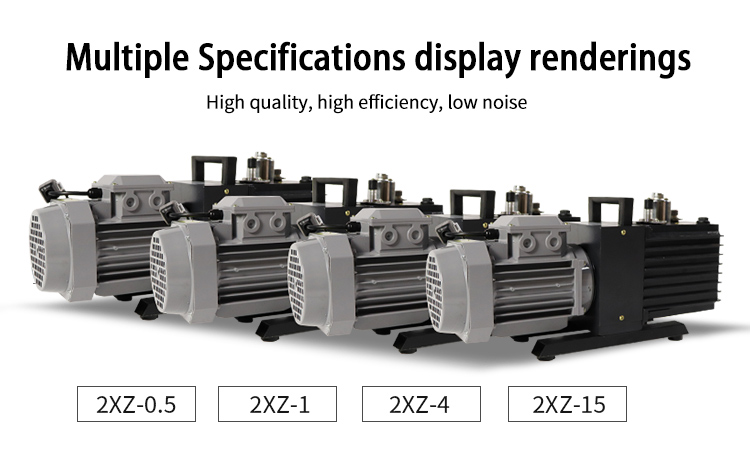

What are the types of rotary vane vacuum pumps?

There are usually two types of rotary vane vacuum pumps: single-stage or double-stage, sometimes called double-stage. The second stage is created by connecting the air inlet of the second rotor to the air outlet of the rotor. The advantage of the two-stage rotary vane pump is that a lower vacuum degree and a higher volume flow can be obtained in this way.

MODEL | 2XZ-0.5 | 2XZ-1 | 2XZ-2 | 2XZ-4 | 2XZ-8 | 2XZ-15 | |

Exhausting Speed(L/S) | 0.5 | 1 | 2 | 4 | 8 | 15 | |

Ult.Vacuum(Pa) | Without Gas Ballast | ≤6×10-2 | |||||

With Gas Ballast | ≤6.5 | ≤1.33 | |||||

Rotary Speed (r/min) | 1400 | 1410 | |||||

Working Voltage(V) | 220 | 220/380 | |||||

Motor Power(kW) | 0.18 | 0.25 | 0.37 | 0.55 | 1.1 | 1.5 | |

Inlet Diameter(mm) | Φ16 | Φ25 | Φ40 | ||||

Temp. Rise of Pump Oil(℃) | ≤40 | ≤45 | ≤65 | ≤70 | |||

Oil Capacity(L) | 0.5 | 0.55 | 0.8 | 0.1 | 2.5 | 4 | |

Size(W*D*H, mm) | 445*130*254 | 467*130*254 | 488*145*280 | 528*145*280 | 575*172*350 | 703*338*453 | |

Weight(kg)(With3-phase Motor) | 13.5 | 15 | 20 | 23 | 48.5 | 77.5 | |

Noise(Db) | ≤60 | ||||||

Vibration Reference Number(U) | ≤80 | ||||||