The advantages of circulating water vacuum pumps:

Circulating water vacuum pump is a kind of laboratory vacuum generator that uses water jet to generate vacuum. Provide vacuum conditions for evaporation, distillation, crystallization, drying, sublimation, filtration and pressure reduction, and degassing.

Features of circulating water vacuum pump:

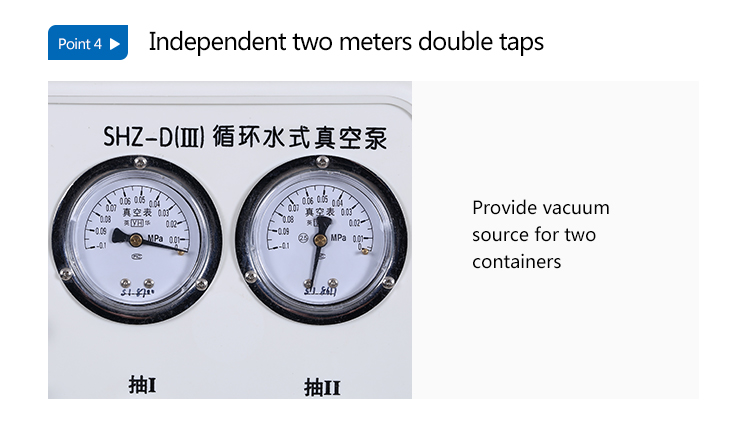

1. It adopts double taps or four taps, which can be used alone or in parallel, equipped with two or four vacuum gauges.

2. There is an ice hole for adding ice when the water temperature is too high and the vacuum is lowered.

3. Recycle water to save water resources.

4. Reasonable design, compact structure, and safe packaging.

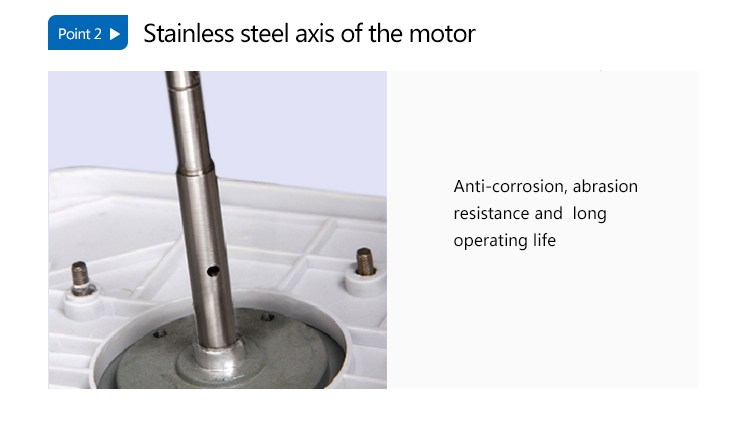

5. The movement is made of stainless steel and anti-corrosion materials.

6. A vacuum degree regulating valve can be installed according to user needs.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

1. What are the models of SHZ-D series circulating water vacuum pumps?

SHZ-D(Ⅲ) and SHZ-D(Ⅲ) four tap.

2. What should I do if the circulating water vacuum pump motor does not work?

Replace a new fuse, replace a new capacitor with the same capacity and voltage as the original, replace a new motor, replace a new bearing, clean up debris, correct the position of the impeller, secure the welding, and tighten the line card.

3. What should I do if the circulating water vacuum pump leaks?

Replace the water tank or sealing ring, and tighten the water nozzle.

4. What are the specific operation methods of the circulating water vacuum pump?

Add water, repeat the machine to stop adding water, and change the water at least once a week. Connect the equipment that needs to be vacuumed to the exhaust nozzle, turn off the cycle switch, turn on the power, and turn on the power switch to start the vacuum operation. Connect the drain hose to the water source (tap water), and the overflow nozzle as a drain outlet. Properly control the amount of tap water to keep the water temperature in the water tank from rising and stabilize the vacuum.

Model | SHZ-D(Ⅲ) | SHZ-D(Ⅲ)four-meter, four tap | Remark | |

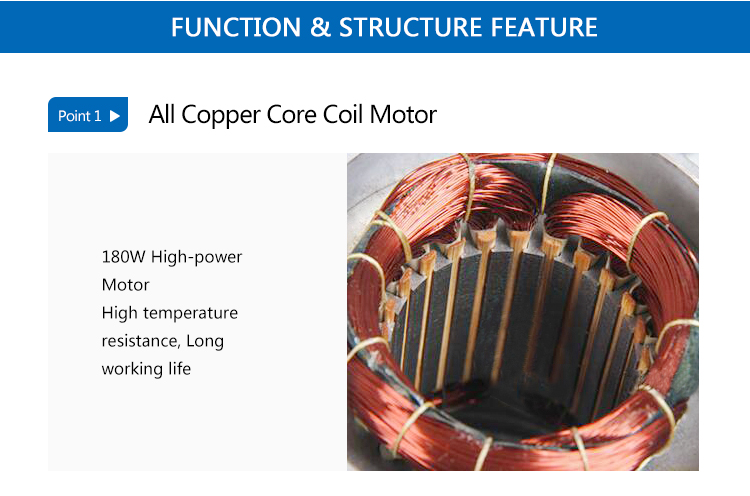

The machine Performance | Power(W) | 180 | 370 | Can equipped with 2L, 5L glass reactor or rotary evaporator, The vacuum is better when the water temperature is between 4℃ and 10℃ |

Voltage(V/Hz) | 220/50 | |||

Flow(L/min) | 60 | |||

Lift(m) | 8 | |||

Body material | Anti-corrosion/1Cr18 | Anti-corrosion | ||

The machine performance | Max. pressure (M Pa) | 0.098 | ||

Sucking rate for single tap(L/min) | 10 | |||

Quantity of tap (Pcs) | 2 | 4 | ||

Tank capacity(L) | 15 | |||

Dimension(mm) | 400*280*420 | |||

Weight(kg) | 15 | |||

Ultimate vacuum(kpa) | 26 | |||

Security performance | Anti~corrosion, counter~current prevent valve | |||