Advantages of stainless steel reactor:

The stainless steel reactor has the characteristics of rapid heating, high temperature resistance, corrosion resistance, and cleanliness. It is widely used in chemical, pharmaceutical, food and other industries.

Features of Stainless steel reactor:

1. Digital display speed and high and low temperature display, easy to operate.

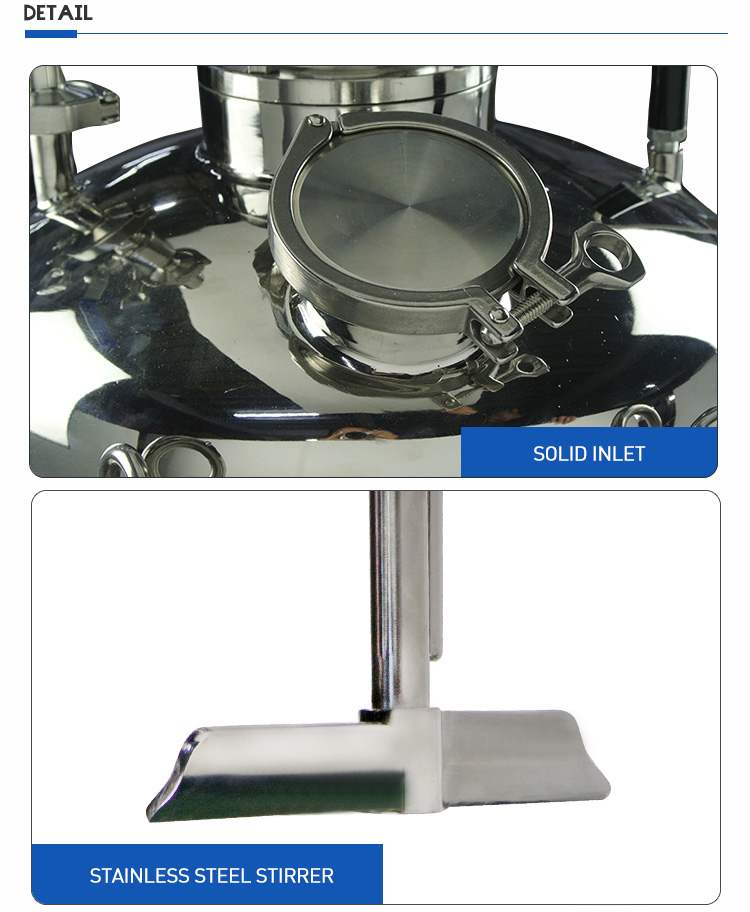

2. The inner surface is mirror polished, which is easy to clean.

3. The fully enclosed design ensures that the material is always in a sterile state

4. You can choose steam heating, electric heating or thermal oil heating.

5. Strong mixing force and stable motor operation.

6. Simple operation and low price.

7. Fast heating, high temperature resistance, no environmental pollution.

8. The overall new stainless steel frame structure, compact, firm and unchanging; with brake angle wheels, easy to move.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

SHZ-C circulating water vacuum pump

DLSB low temperature coolant circulation pump

GYY circulating water (oil) bath

GDX high and low temperature integrated machine

FAQ:

What should be paid attention to in the operation of stainless steel reactor?

1. The agitator should be turned on before the stainless steel reaction kettle is charged. When there is no noise and normal, the material is added to the kettle, and the number of materials added should not exceed the process requirements.

2. It is necessary to strictly follow the process requirements and add materials in order, and do not change the order of materials at will.

3. After the feeding is finished, the temperature starts to rise. It is not allowed to increase the temperature too fast or too slowly. The temperature must be slowly raised to the appropriate temperature for the vacuum reaction of the material within a regular time.

4. The temperature of the kettle should be checked at any time during the heat preservation process, and corresponding records should be made. When the temperature of the kettle is abnormal, measures should be taken in time and the normal vacuum reaction temperature should be adhered to.

5. When opening the cooling water valve, open the return valve first, and then the inlet valve. The pressure of the cooling water should be well controlled, not less than 0.1 MPa, and must not be higher than 0.2 MPa.

6. It is necessary to circulate the condensed water discharge during the operation of the vacuum reaction kettle, and the temperature difference between the upper part and the lower part of the kettle should not be greater than 40 degrees. When the condensate discharge is blocked and the vacuum reactor is severely deformed, emergency measures should be taken to discharge the condensate, and the kettle should be stopped if it is still ineffective.

7. Check the operation of the equipment at any time, and stop for maintenance if any abnormal situation is found.

8. After discharging, the residue in the kettle should be rinsed clean. Do not use alkaline water to wash, take care not to damage the enamel.

What are the heating methods of the stainless steel reactor?

The heating method can be steam heating, electric heating, heat conduction oil heating, etc.

What should be paid attention to before starting the stainless steel reactor?

Check whether the water, electricity, and gas meet the safety requirements. Check whether there is any malfunction in the kettle, agitator, indicating instrument, safety valve, pipeline and valve.

Model: | T-80L |

Capacity(L) | 80 |

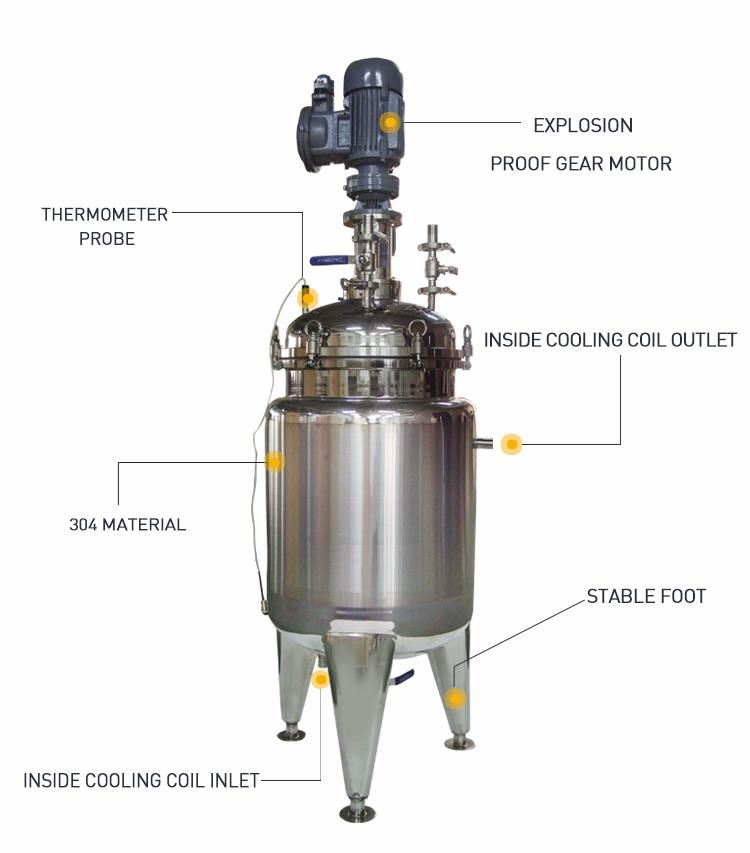

Material | SS304 stainless steel |

Power Supply | 220V 50/60 Hz; 110v 60hz/ 240V60hz |

Stirring Power(W ) | 370 |

Stirring speed(rpm) | 0-180 |