Advantages of stainless steel reactor:

The stainless steel reactor has the characteristics of acid resistance, high temperature resistance, wear resistance and corrosion resistance. There are 50L, 60L, 80L, 100L capacity options and can be customized.

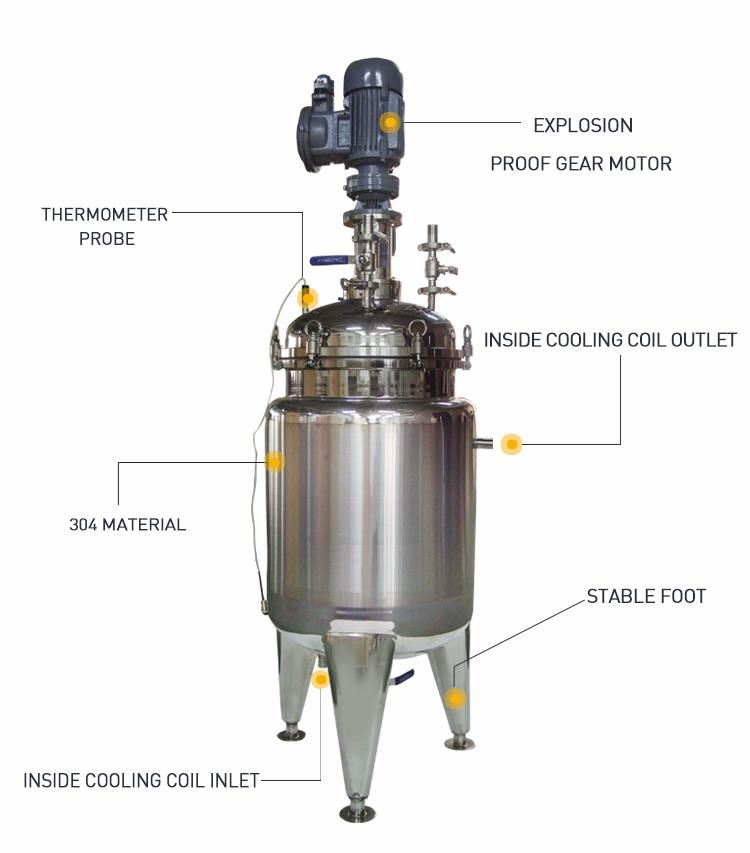

Features of Stainless steel reactor:

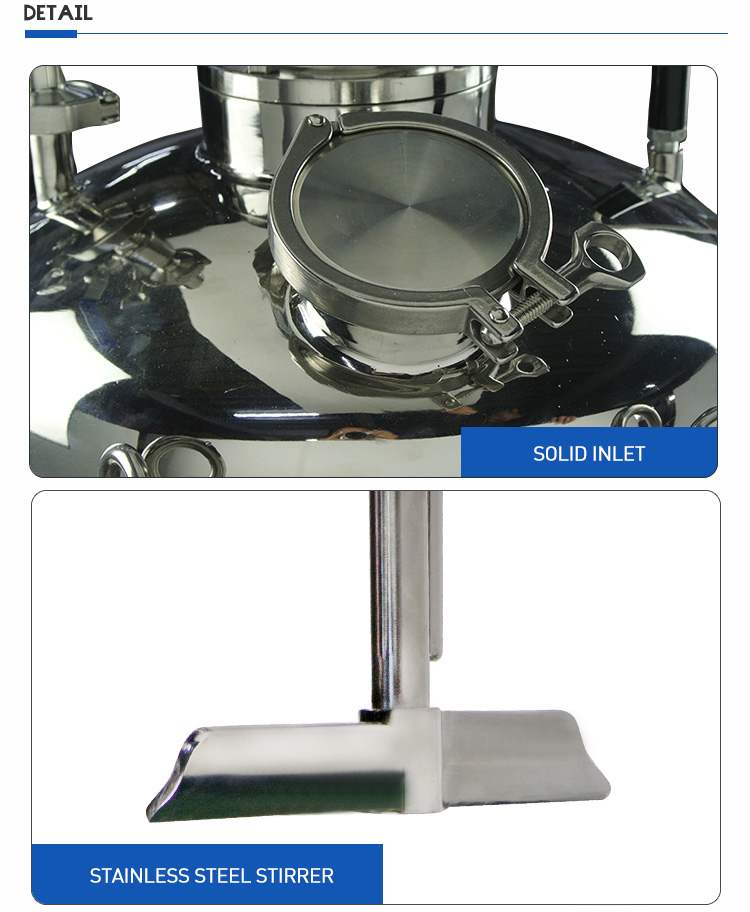

1. The fully enclosed design ensures that the material is always in a sterile state.

2. The material and material contact parts of the stainless steel reactor are made of 304 high-quality stainless steel.

3. Made of 304 stainless steel, with excellent physical and chemical properties.

4. Frequency conversion speed control mixing, stable and reliable operation, large torque, no sparks.

5. It has good corrosion resistance and is not easy to rust.

6. It can withstand higher working pressure, and can also withstand the impact of bulk solid materials when feeding.

7. The overall structure is scientific, novel, practical and beautiful.

8. Mechanical mixing and sealing, good sealing performance.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

SHZ-C circulating water vacuum pump

DLSB low temperature coolant circulation pump

GYY circulating water (oil) bath

GDX high and low temperature integrated machine

FAQ:

1. Precautions for the use of stainless steel reactor:

The reactor is a kind of reaction equipment, and you must pay attention to it when operating it, otherwise it will be damaged due to many reasons and the production will be forced to stop. Many aspects should be paid attention to in the operation of the reactor.

First of all, the reactor must be operated strictly in accordance with the rules and regulations.

Secondly, before operation, carefully check for abnormalities. During normal operation, do not open the upper cover and touch the wiring terminals on the board to avoid electric shock; it is strictly forbidden to operate under pressure; carefully observe the pressure during the pressure test with nitrogen. When the change of the meter reaches the test pressure, immediately close the nitrogen valve switch; the heating speed should not be too fast, and the pressurization should be carried out slowly, especially the stirring speed, which only allows a slow rise.

When the kettle body is heated to a higher temperature, do not touch the kettle body to avoid burns; the temperature should be lowered first after the experiment. No quick cooling is allowed to prevent damage caused by excessive temperature difference and pressure. At the same time, unplug the power supply in time.

At the same time, pay attention to maintenance after the reactor is used, so that the autoclave can have a better service life.

2. What are the components of the stainless steel reactor?

Reactor body, power device, stirring device, heating device, sealing device.

3. What are the heating methods of the stainless steel reactor?

The heating method can be steam heating, electric heating, heat conduction oil heating, etc.

Model: | T-50L |

Capacity(L) | 50 |

Material | SS304 stainless steel |

Power Supply | 220V 50/60 Hz; 110v 60hz/ 240V60hz |

Stirring Power(W ) | 370 |

Stirring speed(rpm) | 0-180 |