Advantages of stainless steel reactor:

The stainless steel reactor has the characteristics of acid resistance, high temperature resistance, wear resistance and corrosion resistance. It is widely used in chemical, pharmaceutical, food and other industries.

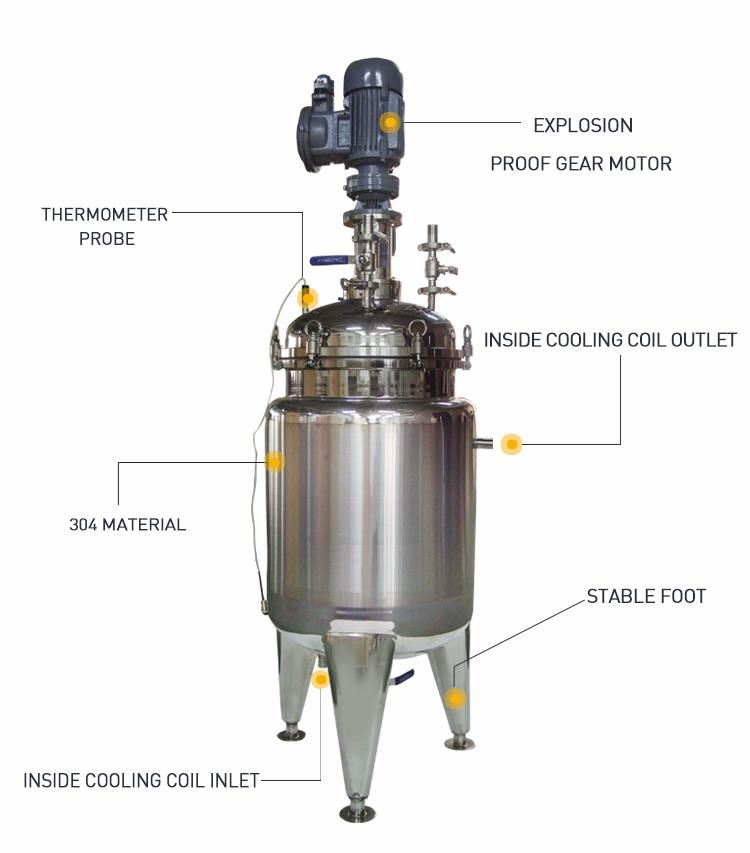

Features of Stainless steel reactor:

1. Frequency conversion digital display stepless speed regulation, AC precision geared motor drives the stirring, strong stirring force, no brush.

2. Good heat resistance, the temperature range can reach -196~600℃.

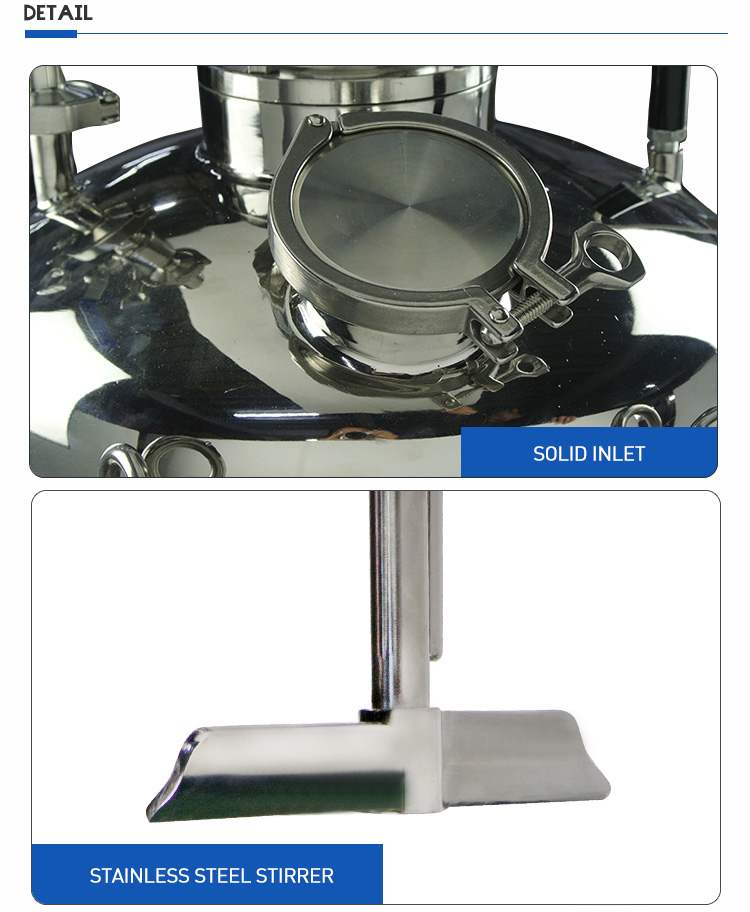

3. The inner surface is mirror polished, which is easy to clean.

4. Optional frame type, anchor type, paddle type, and mixing method to ensure uniform mixing of materials.

5. Fast heating, high temperature resistance, no environmental pollution.

6. The stainless steel reactor has a good heat transfer effect, and the heating and cooling speed is fast.

7. The PTFE components are sealed, and the proprietary technology can maintain high vacuum (about -0.095mpa).

8. Regardless of cooling or heating, related products can be produced according to customer requirements.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

SHZ-C circulating water vacuum pump

DLSB low temperature coolant circulation pump

GYY circulating water (oil) bath

GDX high and low temperature integrated machine

FAQ:

What should be paid attention to before the operation of stainless steel reactor?

1. The operator of the stainless steel reactor must be trained, familiar with the structure and performance of the equipment, and be proficient in the equipment operating procedures.

2. Check whether the kettle, agitator, rolling parts, auxiliary equipment, indicating instruments, safety valves, pipelines and valves meet the safety requirements.

3. Check the autoclave body, cover and all welds for abnormal phenomena such as cracks, deformation, leakage, etc.; the corrosion of the inner and outer surfaces of the body and cover; whether the safety accessories can work normally; whether the condensate discharge equipment Normal; whether the kettle cover suspension equipment and the hand-cranked reducer are sensitive; whether the rolling support is sensitive, whether the foundation is sinking; whether all the fasteners are loose, etc.

4. Check whether the water, electricity and gas meet the safety requirements.

5. After the inspection of related items is completed, it can start normally.

What is the capacity of your stainless steel reactor?

We have 50L, 60L, 80L, 100L stainless steel reactors, if you need other capacities, we can customize them.

What is the speed of the stainless steel reactor?

0-180rpm.

Model: | T-60L |

Capacity(L) | 60 |

Material | SS304 stainless steel |

Power Supply | 220V 50/60 Hz; 110v 60hz/ 240V60hz |

Stirring Power(W ) | 370 |

Stirring speed(rpm) | 0-180 |