Advantages of stainless steel reactor:

The stainless steel reactor is used in the production process of hydrolysis, neutralization, crystallization, distillation, evaporation and other processes in the pharmaceutical, chemical, and food industries. Acid resistance, high temperature resistance, wear resistance and corrosion resistance.

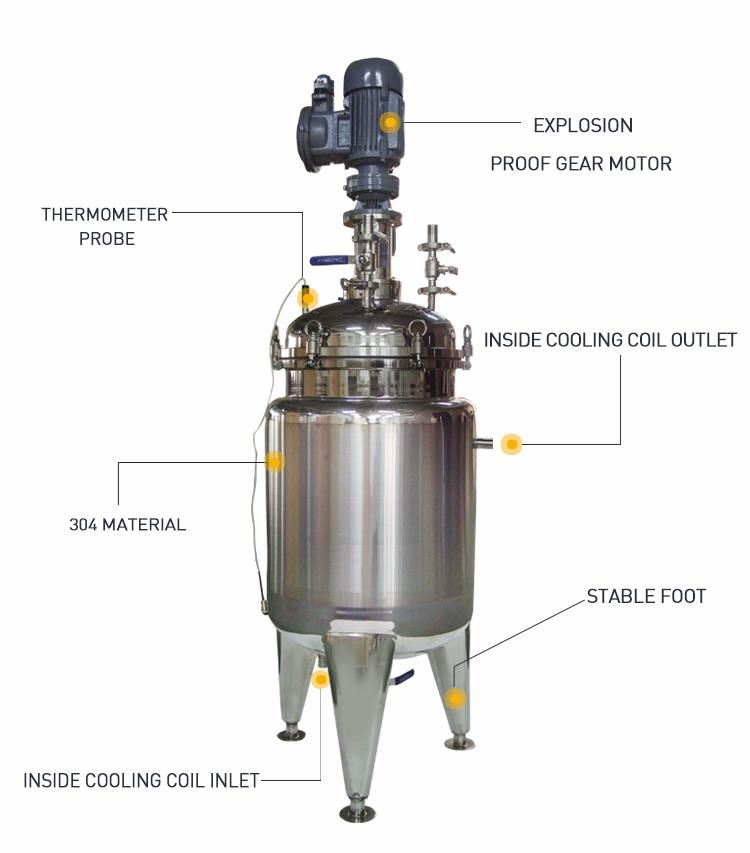

Features of Stainless steel reactor:

1. High efficiency, long continuous operation time and good stability.

2. Made of 304 and 316 high quality stainless steel.

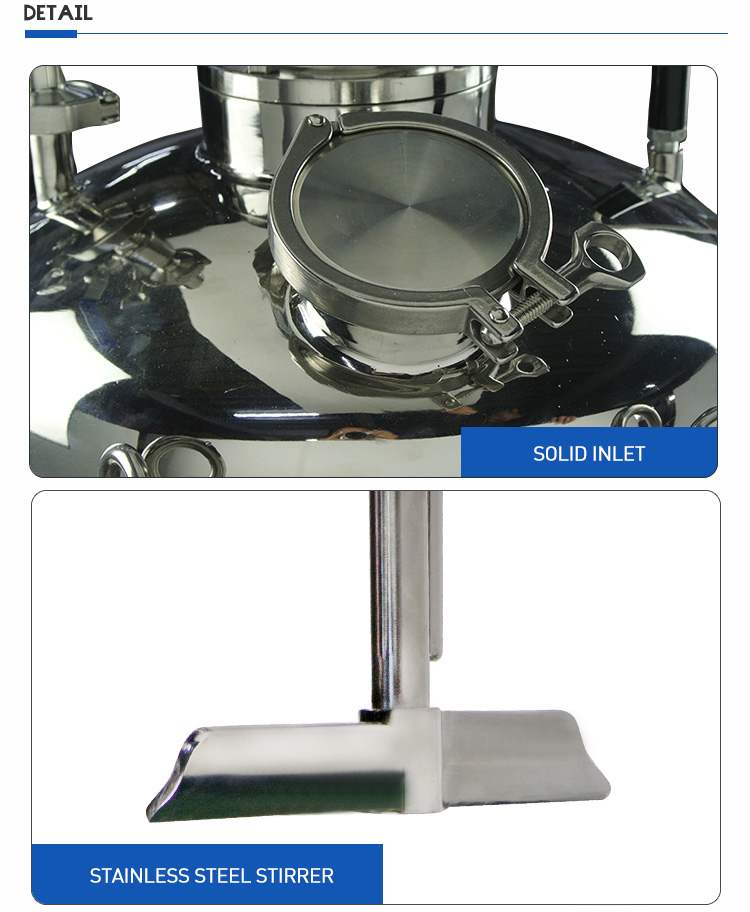

3. Strong stirring force, no brushes, no sparks.

4. The structure is scientific, compact, strong and beautiful.

5. The PTFE discharge valve without dead ends, the body and the lid are also customized according to customer requirements.

6. The heating (cooling) solution of the reaction interlayer can be completely removed after the reaction is completed, and there is no accumulation of liquid.

7. The lid of the kettle has a trial lens port, which can observe the reacted materials, the feeding port, and it can be fed quickly. It is equipped with a pressure gauge and can also be used for positive pressure reaction.

8. The material is in contact with 304 stainless steel, no cross-contamination

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

SHZ-C circulating water vacuum pump

DLSB low temperature coolant circulation pump

GYY circulating water (oil) bath

GDX high and low temperature integrated machine

FAQ:

1. What is the working principle of the stainless steel reactor?

The reaction material can be put into the inner layer of the stainless steel reactor to perform a stirring reaction. The hot solvent or cooling medium is injected through the interlayer of the stainless steel reactor to cool or heat the materials in the reactor. At the same time, the stirring reaction can be carried out under normal pressure or negative pressure according to the requirements of use. The materials are reacted in the reaction kettle, and the evaporation and reflux of the reaction materials are controlled. After the reaction is completed, the materials will be discharged from the discharge port at the bottom of the kettle.

2. What should be paid attention to when feeding stainless steel reactor?

When adding materials, do not directly add large pieces of harder materials, but small pieces. Avoid metal and other hard objects falling into the container. Do not add cold material to the hot kettle or the heating material of the cold kettle when adding materials to the stainless steel reaction kettle.

3. How to maintain the stainless steel reactor?

Check the working condition of the equipment frequently; check the safety valves, thermometers, distillation holes, pressure gauges, electrical instruments, etc. regularly; when the equipment is not in use, it should be scrubbed frequently to keep the exterior clean and the inner tank bright to achieve the purpose of durability.

Model: | T-100L |

Capacity(L) | 100 |

Material | SS304 stainless steel |

Power Supply | 220V 50/60 Hz; 110v 60hz/ 240V60hz |

Stirring Power(W ) | 370 |

Stirring speed(rpm) | 0-180 |