Advantages of hydrothermal autoclave reactor:

The hydrothermal synthesis reactor is a reactor used to synthesize chemical substances at a certain temperature and pressure. It is widely used in scientific research experiments in new materials, energy, environmental engineering and other fields.

Features of hydrothermal autoclave reactor:

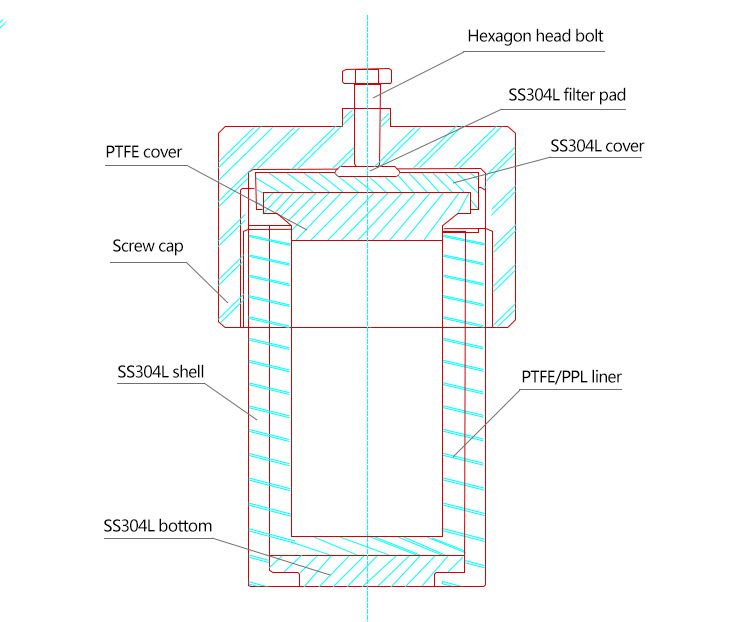

1. With explosion-proof function, the shell is made of high-quality 304 stainless steel, with good corrosion resistance, no harmful substances overflow, reducing pollution and safe use.

2. Quickly and non-destructively dissolve samples that are difficult to dissolve under normal conditions, as well as samples containing volatile elements after temperature rise and pressure rise.

3. Beautiful appearance, reasonable structure, simple operation, short analysis time and reliable data.

4. High temperature resistance: -200℃~240℃, pressure: 0~6MPa.

5. The internal material is made of PTFE, which has the characteristics of acid and alkali resistance.

6. After the temperature is increased and the pressure is increased, it can quickly and without damage to dissolve some reagents that are difficult to dissolve under normal conditions and reagents containing volatile elements.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

What is a hydrothermal autoclave reactor?

The hydrothermal reactor is a closed container that can decompose insoluble substances. It can be used for sample dissolution pretreatment in atomic absorption spectroscopy and plasma emission analysis; it can also be used for small-dose synthesis reactions; it can also use strong acid or alkali in the tank and the high temperature and high pressure airtight environment to achieve the purpose of rapid digestion of insoluble substances . Do sample pretreatment in chemical analysis methods such as gas phase, liquid phase, plasma spectroscopy mass spectrometry, atomic absorption and atomic fluorescence. It is a right-hand man for digesting samples in the determination of trace elements and trace elements. It can be used in the determination of heavy metals such as lead, copper, cadmium, zinc, calcium, manganese, iron, mercury, etc. It can also be used as a high-temperature, high-pressure, corrosion-resistant and high-purity reaction vessel, as well as organic synthesis, hydrothermal synthesis, crystal growth or Sample digestion, extraction and other aspects. Dissolve heavy metals, pesticide residues, food, silt, rare earths, aquatic products, organics, etc. before the sample. Therefore, it is widely used in research and production in petrochemical, biomedicine, materials science, geochemistry, environmental science, food science, commodity inspection and other departments.

What are the models of hydrothermal synthesis reactor?

KH-15, KH-25, KH-30, KH-50, KH-100, KH-150, KH-200, KH-250, KH-300, KH-400, KH-500, KH-1000, etc.

What is the operation method of hydrothermal synthesis reactor?

The reactant refers to the kettle body, and the feed coefficient is less than 0.8. When the reactant system is corrosive, it should be placed in a tetrafluoroethylene bushing to ensure that the kettle body is not corroded. Place the synthesis kettle in the heater and raise the temperature to the required reaction temperature (less than the specified safe use temperature) according to the specified heating rate. When the temperature is lowered after the reaction is over, it must be operated in strict accordance with the specified cooling rate to facilitate safety and the service life of the reactor. After confirming that the intra-abdominal temperature is lower than the boiling point of the solvent of the reactant system, the kettle cover can be opened for subsequent operations. The reactor should be cleaned in time after each use to avoid corrosion. Particular attention should be paid to clean the seals of the kettle body and the kettle cover line, and take care to prevent them from being bruised or damaged.

Hydrothermal Synthesis Reactor | ||||||||||||

Model | KH-15 | KH-25 | KH-30 | KH-50 | KH-100 | KH-150 | KH-200 | KH-250 | KH-300 | KH-400 | KH-500 | KH-1000 |

Material | Kettle body is stainless steel and the liner is PTFE | |||||||||||

Capacity(ml) | 15 | 25 | 30 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 500 | 1000 |

Remarks | Safe temperature is 200℃. Max. Pressure is 3 Mpa | |||||||||||