Advantages of high pressure reactor:

Stainless steel simple high-pressure reactor is a simple high-pressure reactor produced according to customer requirements according to the functional characteristics of the autoclave. It can be placed in stainless steel such as electric blast drying furnace, constant temperature oil/water bath, low temperature tank, etc. Small simple high pressure reactor system autoclave is suitable for mixing flammable, explosive, highly toxic, precious media and strong permeable chemical media. It is the best non-leakage reaction for vulcanization, fluorination and oxidation of petroleum, chemical industry, organic synthesis, polymer, food and other processes.

Features of high pressure reactor:

1. The body and lid of the kettle are made of high-quality stainless steel. The simple stainless steel high-pressure reactor body is connected with flanges through threads.

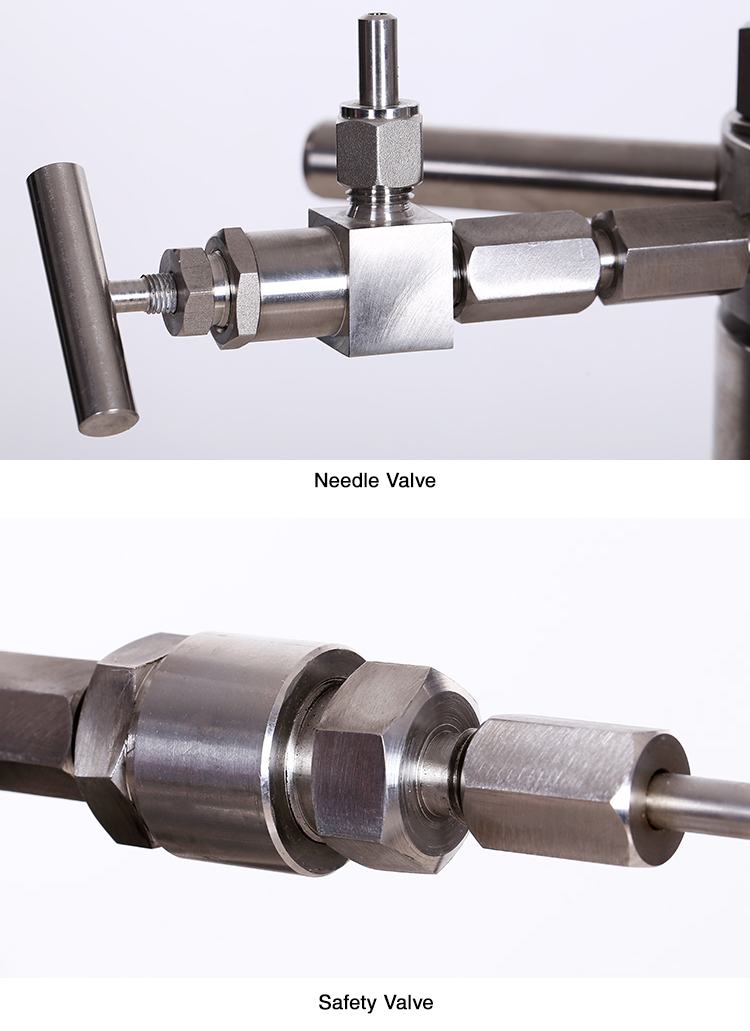

2. Has a good sealing effect.

3. The temperature can be controlled by the PID temperature control system.

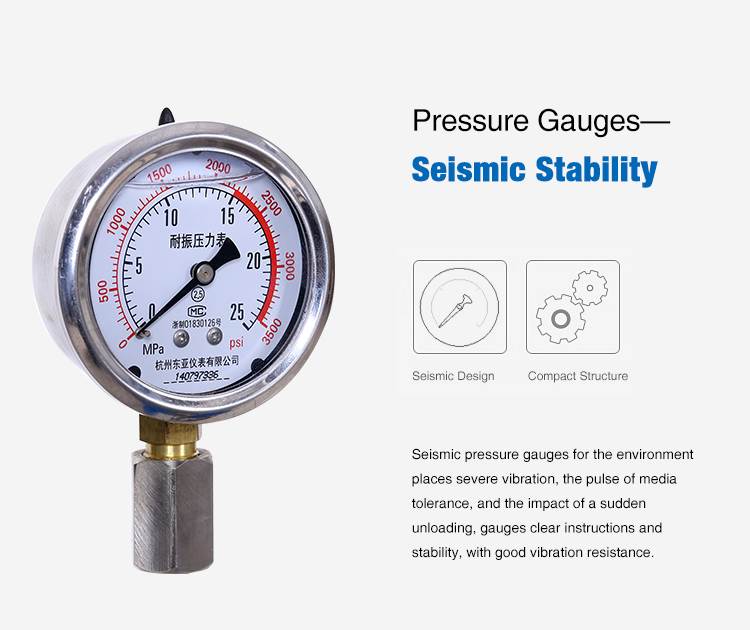

4. Cooling rate ≤5°C/min. The safety pressure is 22 MPa.

5. Beautiful appearance, reasonable structure and simple operation.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

What is the working principle of CJF series high pressure stirred tank?

CJF series laboratory magnetic stirring reactor is a gas-liquid, liquid-liquid, liquid-solid or gas-liquid-solid three-phase chemical material. It is used in chemical reaction stirring reaction equipment to make various chemical materials under higher pressure and stirring. Carry out fully under vacuum and temperature to enhance mass and heat transfer.

Repair and maintenance of simple high pressure reactor:

When using the CF stainless steel simple autoclave, you must close the refrigerant inlet valve, drain the remaining refrigerant in the pot and jacket, and then input the material, turn on the stirrer, and then turn on the steam valve and electric heating power supply. After reaching the required temperature, Turn off the steam valve and electric heating power first, after 2 to 3 minutes, turn off the stirrer. After processing, after the remaining condensate in the pot and jacket is drained, rinse with warm water as soon as possible to brush off the sticky materials. Then use 40℃~50℃ alkaline water to clean the inner wall of the container, and rinse with clean water. Especially when there is no material (heat absorption medium) in the stainless steel reactor pot, the steam valve and electric heating power supply should not be opened. Pay special attention to the use of steam pressure. , Shall not exceed the fixed working pressure.

Model | Volume(L) | DesignedPressure(Mpa) |

CF-0.025 | 0.025 | 22 |

CF-0.05 | 0.05 | 22 |

CF-0.1 | 0.1 | 22 |

CF-0.2 | 0.2 | 22 |

CF-0.25 | 0.25 | 22 |

CF-0.3 | 0.3 | 22 |

CF-0.5 | 0.5 | 22 |

CF-1 | 1 | 22 |

CF-2 | 2 | 22 |

CF-3 | 3 | 22 |

CF-5 | 5 | 22 |

CF-7 | 7 | 22 |

CF-10 | 10 | 22 |

CF-20 | 20 | 22 |