Advantages of high pressure stirred autoclave:

The main feature of the stainless steel high-pressure reactor is the static sealing structure, which uses static sealing instead of dynamic sealing. The stirrer and the motor drive are connected through a magnetic coupler. The non-contact torque transmission completely solves the problem of poor sealing of materials during direct stirring. The entire medium and the stirring part are completely sealed. The stainless steel high-pressure reactor is more suitable for various flammable, explosive, highly toxic, precious media and other chemical media with strong permeability. It is a process of petroleum, chemistry, organic synthesis, polymer material polymerization, food and so on. The most ideal non-leakage reaction equipment for vulcanization, fluorination, hydrogenation, etc.

Features of high pressure stirred autoclave:

1. Various chemical materials can be fully stirred under higher pressure, vacuum and temperature to strengthen the mass transfer and heat transfer process;

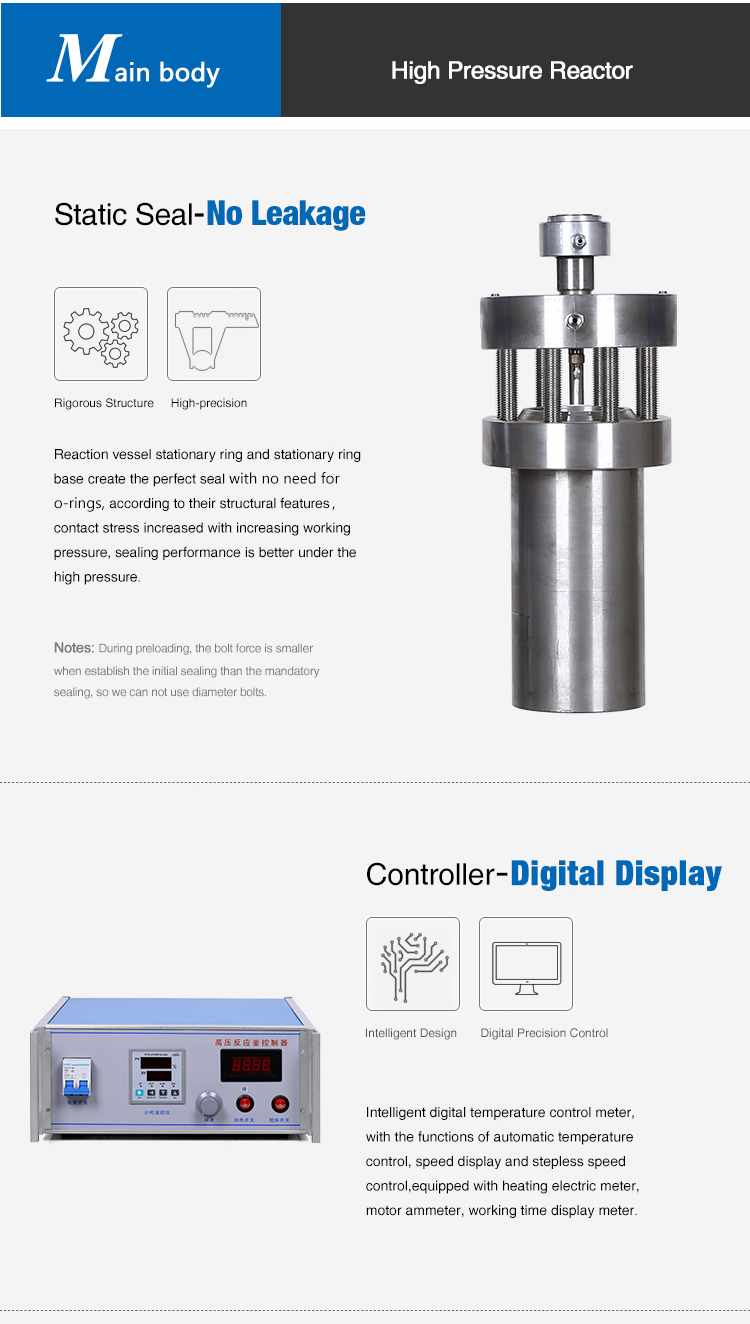

2. Static sealing, no leakage, the sealing between the static ring of the reactor and the static ring seat, no O-ring, depending on the respective structural characteristics, the contact stress increases with the working pressure, and the sealing performance is better under high pressure it is good;

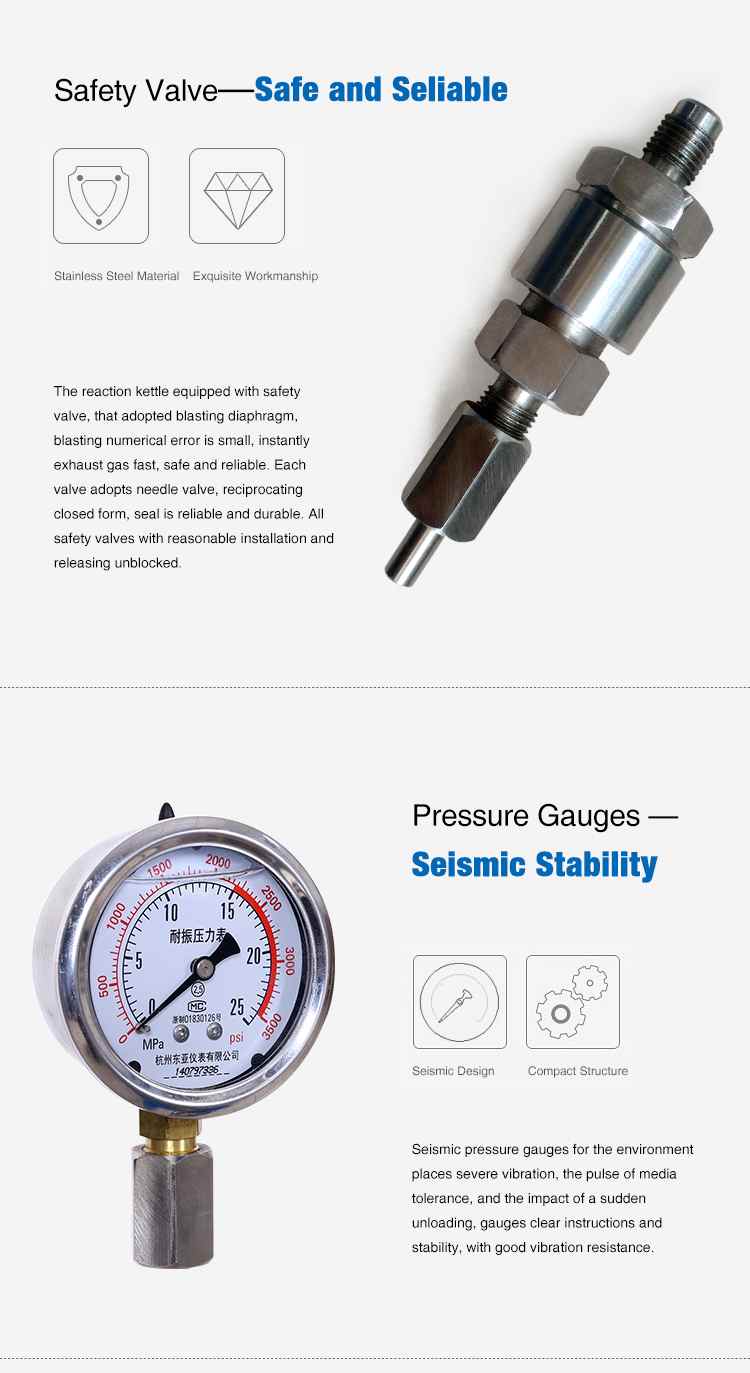

3. The safety valve of the stainless steel high-pressure reactor adopts a blasting diaphragm, the blasting value error is small, the instantaneous exhaust speed is fast, and it is safe and reliable;

4. Each valve of the stainless steel high-pressure reactor adopts a needle valve, which is closed in reciprocating manner, and the seal is reliable and durable. The installation of various valves is reasonable and the discharge is unobstructed;

5. The pressure gauge of the stainless steel high-pressure reactor has good anti-vibration performance and is suitable for places with severe environmental vibration. It can withstand the pulsation, impact and sudden unloading of the medium, and the indicator is stable and clear;

6. Intelligent digital temperature control meter, with automatic temperature control function, speed display and stepless speed regulation function, equipped with heating electric heat meter, motor ammeter, working time display meter.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

What are the models of FCF series high pressure stirred autoclave?

FCF-0.1, FCF-0.25, FCF-0.5, FCF-1, FCF-2, FCF-3, FCF-5, FCF-10, FCF-20, FCF-30, etc.

What are the components of the FCF series high pressure stirred autoclave?

It is composed of kettle body, kettle cover, magnetic stirrer, heater, valve, feed port, internal cooling coil, safety sandblasting device, pressure gauge, controller and lifting device.

Application range of small high pressure stirred autoclave

Widely used in scientific research fields: petrochemical, chemical, pharmaceutical, polymer, metallurgy, environmental protection and other chemical process fields; such as high pressure reaction, hydrogenation reaction, catalytic reaction, drug synthesis, high pressure polymerization, nano synthesis, condition screening, crystallization screening, combination Chemistry, biomass conversion, supercritical reaction, hydrothermal reaction, polymer synthesis, electrochemical corrosion test, infrared detection, etc.

Model | FCF-0.05 | FCF-0.1 | FCF-0.25 | FCF-0.5 | FCF-1 | FCF-2 | FCF-3 | FCF-5 | FCF-10 |

Capacity(L) | 0.05 | 0.1 | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 |

Setting Pressure(MPa) | 22 | ||||||||

Setting Temperature(℃) | 350 | ||||||||

Accuracy of Temperature Control | ±1 | ||||||||

Heating Method | General electric heating, others are far-infrared, thermal iol, steam, circulating water, etc | ||||||||

Stirring Torque(N.cm) | 120 | ||||||||

Heating Power(kw) | 0.6 | 0.8 | 1.5 | 2 | 2.5 | 4 | 7 | ||

Temperature Controller | Real-time display and adjust the speed, temperature, time, with standard PID automatic temperature adjustable meter. | ||||||||

Working Environment | Ambient Temperature 0~50℃,Relative Humidity 30~80%. | ||||||||

Voltage(V/Hz) | 220 50/60 | ||||||||