Advantages of Jacketed glass reactor:

S-1L S-2L S-3L S-5L double-layer glass reactor, also known as: small laboratory glass reactor, small glass reactor, laboratory small glass reactor, the double-layer glass reactor produced by our company has convenient operation, beautiful appearance, With novel and practical structure, it is widely used in chemical, pharmaceutical and other fields.

Features of Jacketed glass reactor:

1. The glass components are all high borosilicate glass 3.3, with excellent physical and chemical properties.

2. It can be used in the range of high temperature (200℃) to low temperature (-80℃).

3. It can work under pressure conditions of -0.1 MPa~0.0 MPa.

4. Paddle type stirring blade, PTFE stirring blade; the stirring rod is made of SUS304, wrapped with PTFE, with high strength and strong corrosion resistance.

5. Easy to discharge, no residue.

6. The temperature and speed adopt digital display, which is easy to observe and adjust the material reaction.

7. High efficiency, long running time, good stability and no noise.

8. Frequency conversion speed regulation or electronic stepless speed regulation, AC precision geared motor drives the stirring, strong stirring force, no brushes, no sparks.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technicians put forward reasonable suggestions based on the use of the product, and assist the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

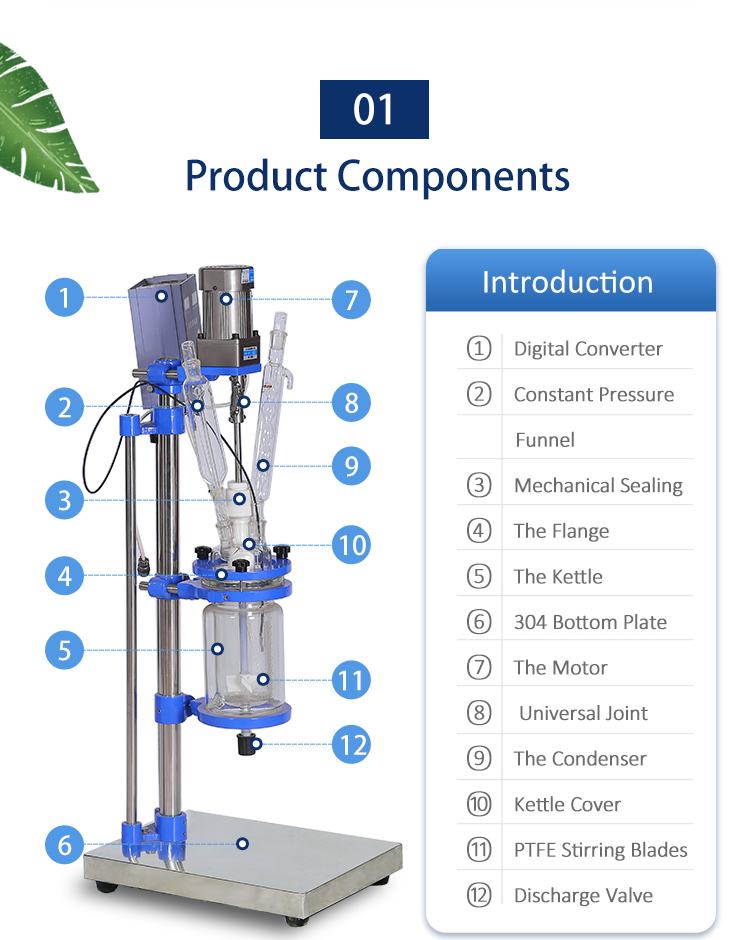

Grouped equipment:

SHZ-C circulating water vacuum pump

DLSB low temperature coolant circulation pump

GYY circulating water (oil) bath

GDX high and low temperature integrated machine

FAQ:

1. What is the working principle of the double-layer glass reactor?

The glass reactor is sandwiched by the double-layer reactor, and a constant temperature (high or low temperature) hot melt or cooling medium is injected to heat or cool the materials in the reactor at a constant temperature, and the double-layer glass reactor can provide stirring. The materials are reacted in the reaction kettle, and the evaporation and reflux of the reaction solution can be controlled. After the reaction is completed, the materials can be discharged from the discharge port at the bottom of the kettle, and the operation is extremely convenient.

2. Why should the glass reactor be kept warm?

Pay attention to heat preservation. Due to the small thickness of the interlayer in the middle of the glass reactor, the thermal insulation performance is poor. In the process of using high temperature and low temperature, users need to use insulation materials to protect the kettle body. At the same time, the user needs to wrap the reactor body and the liquid-conducting pipe with insulation materials, and pay attention to the thickness of the insulation layer to ensure a better insulation effect.

3. How to choose temperature control medium for glass reactor?

Generally speaking, users will select temperature control media of different properties as the heat transfer medium for the reaction according to the required reaction temperature. Choose ethanol bath for low temperature, water bath for normal temperature, and oil bath for high temperature.

4. What is the supporting equipment for the low-temperature reaction of the double-layer glass reactor?

High and low temperature integrated machine: It has both heating and cooling functions, and provides heating and cooling sources for the double-layer kettle in a circular manner, and intelligent temperature control

Low-temperature coolant circulating pump: refrigeration equipment, in a circulating manner, provides low-temperature cooling circulating water for the condensation system of the double-layer kettle, and the condensing medium is ethanol

Model | S-1L | S-2L | S-3L | S-5L |

Stirring Power(W ) | 60 | |||

Stirring Speed(rpm) | 0~600(Max. 1300) | |||

Stirring Shaft Diameter | 12 | |||

Reaction Kettle Capacity(L) | 1 | 2 | 3 | 5 |

Power Supply | 220V 50/60 Hz | |||

Motor Torque(g/cm) | 2000 | 2400 | 4800 | |

Note | Floor type | |||

Explosion-proof

| The stirring power (W): 180, 250, 370 | |||

Power supply: 220V / 50Hz or 110V / 60Hz | ||||

110 V/60Hz can be customized | ||||