Advantages of single layer glass reactor:

The single-layer glass reactor is highly efficient, stable, beautiful, and durable. The single-layer glass reactor is a multifunctional reactor that can perform various biological, chemical, and synthetic reactions under constant temperature conditions, and it can also be refluxed at different temperatures. Or distillation.

Features of single layer glass reactor:

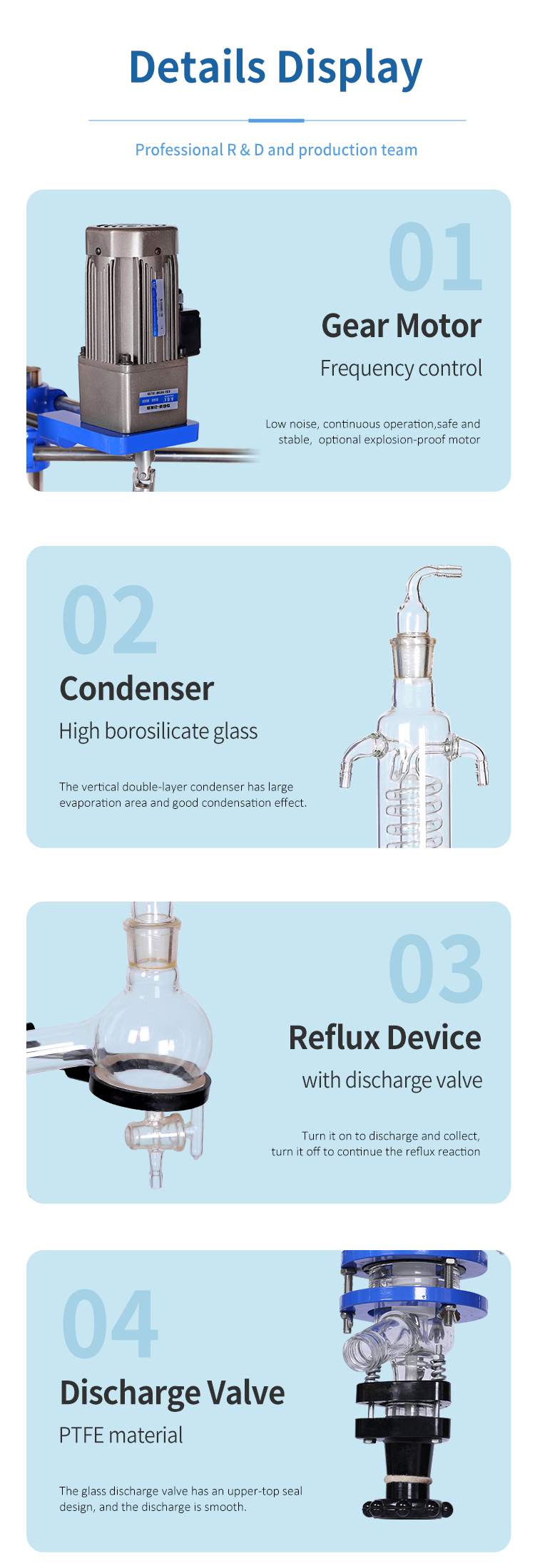

1. Double reflux, integrated standard port condenser

2. Large bottom port design, fast discharge speed, easy to clean

3. Sealing mechanical parts are made of PTFE, with high vacuum

4. The glass parts are made of GG17 high borosilicate glass, which is resistant to strong acid and can withstand the experimental temperature -100~400℃

5. Provide explosion-proof series, which is safer

6. Distillation and reflux can be carried out at the same time

7. Large-caliber discharge valve can discharge solid and liquid materials

8. Efficient and stable, beautiful and generous, durable

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technicians put forward reasonable suggestions based on the use of the product, and assist the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

Low temperature coolant circulation pump

SHZ-C circulating water vacuum pump

FAQ:

1. What should be paid attention to when using single-layer glass reactor?

The glass parts should be cleaned, and a small amount of vacuum silicone grease should be applied to each standard port, ball grinding port and sealing surface to increase air tightness. The power supply voltage of the workplace must be consistent with the requirements of the glass reactor. High-speed operation is not suitable for no-load, glass reaction When the kettle needs to be heated, the temperature should be gradually increased.

2. What are the components of the single-layer glass reactor?

Glass part, stirring part, sealing part, supporting bracket part, heating and cooling part.

3. How to cool down the single-layer glass reactor?

The cooling method of the single-layer kettle is to circulate the cold medium through the cooling coil on the inner wall of the heating tank. After cold exchange with the heating medium, it is transferred to the material in the kettle. Generally, it can only be used for forced cooling of the material.

4. Why should a single-layer glass reactor be matched with a low-temperature coolant circulation pump?

The refrigeration equipment provides low-temperature cooling circulating water for the condensing system of the double-layer kettle in a circulating manner, and the condensing medium is ethanol; it can also be used for cooling coil circulation to force the temperature of materials

Model | F-10L | F-20L | F-30L | F-50L |

Voltage(V/Hz) | 220 50/60 | |||

Stirring Power(W) | 120 | |||

Stirring Speed(rmp) | 60~600 | |||

Capacity(L) | 10 | 20 | 30 | 50 |

Heating Power(kW) | 3 | 4.5 | 6 | |

Heating Mantle Power (kw) | 2.1 | 3 | 3.8 | 5 |

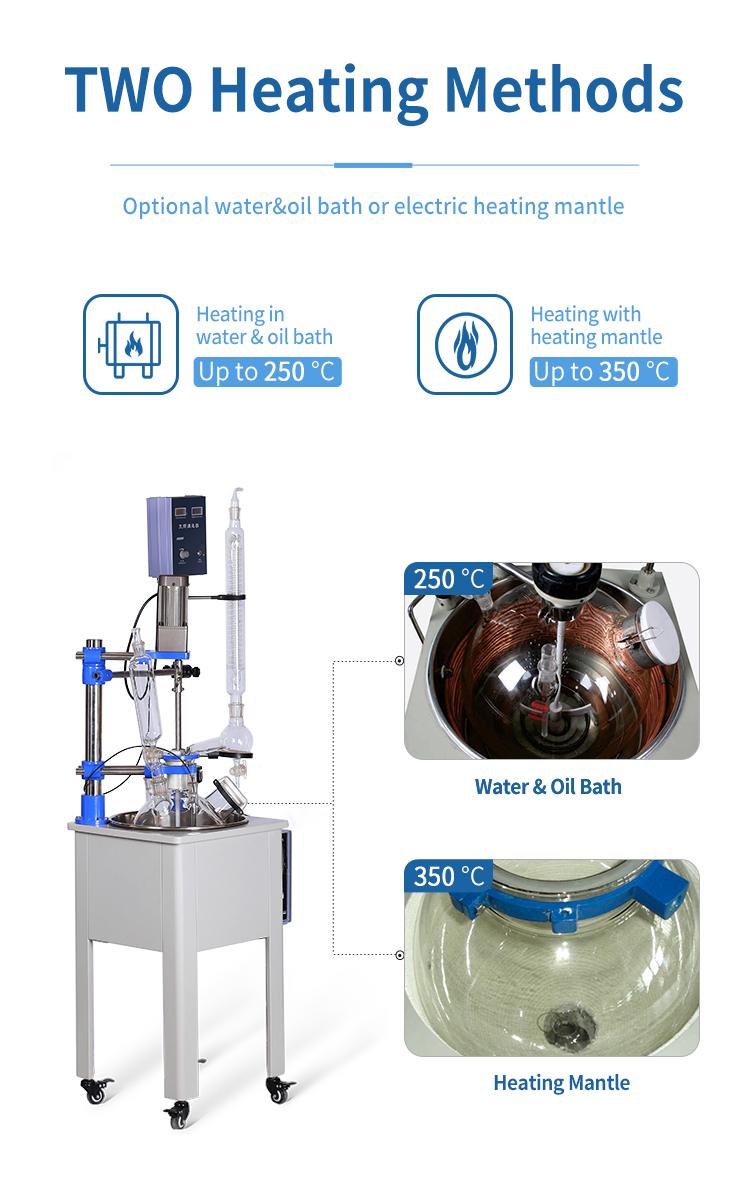

Temperature Using Range(℃) | RT-250 | RT-350 | |||

Motor Torque(g/cm) | 1000 | 1200 | 1500 | |