Advantages of stainless steel centrifuge:

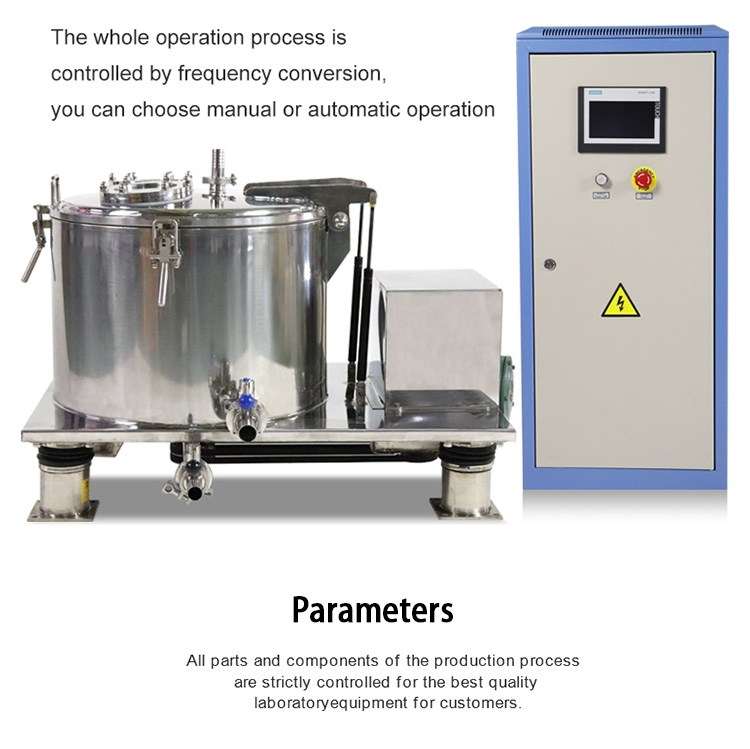

The stainless steel centrifuge has aseptic, hygienic, airtight explosion-proof, multiple safety protection and multiple configuration options, controlled by a fully automatic program, and is widely used in the pharmaceutical, fine chemical and food industries.

Features of stainless steel centrifuge:

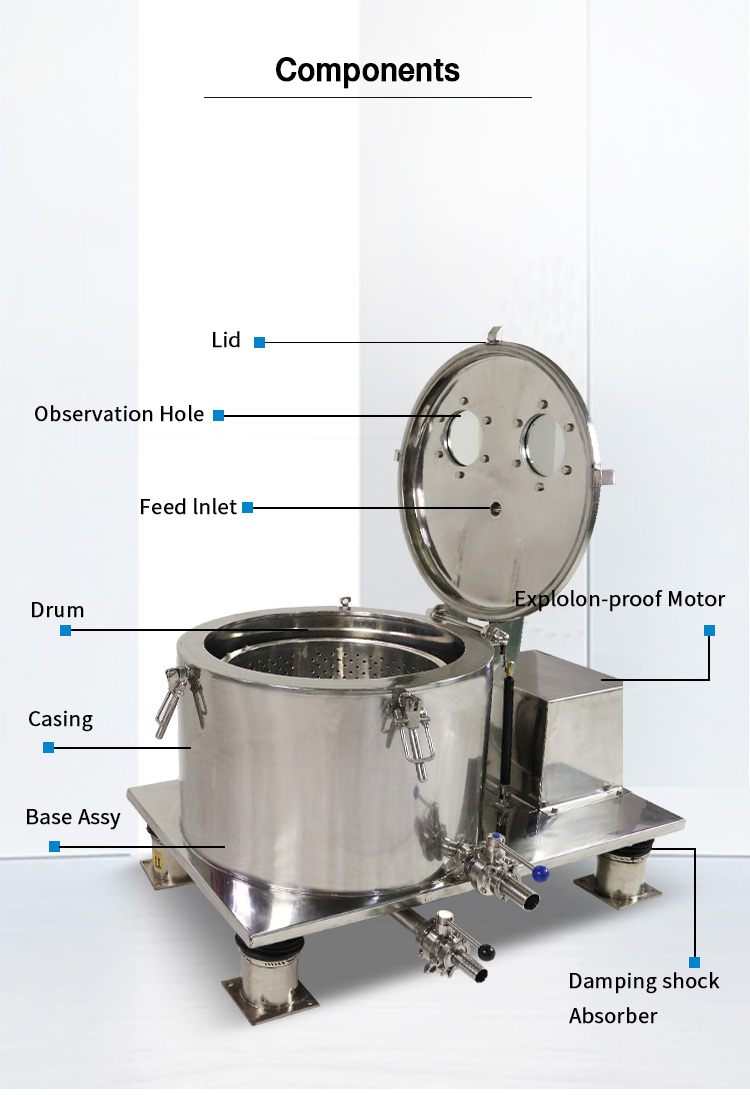

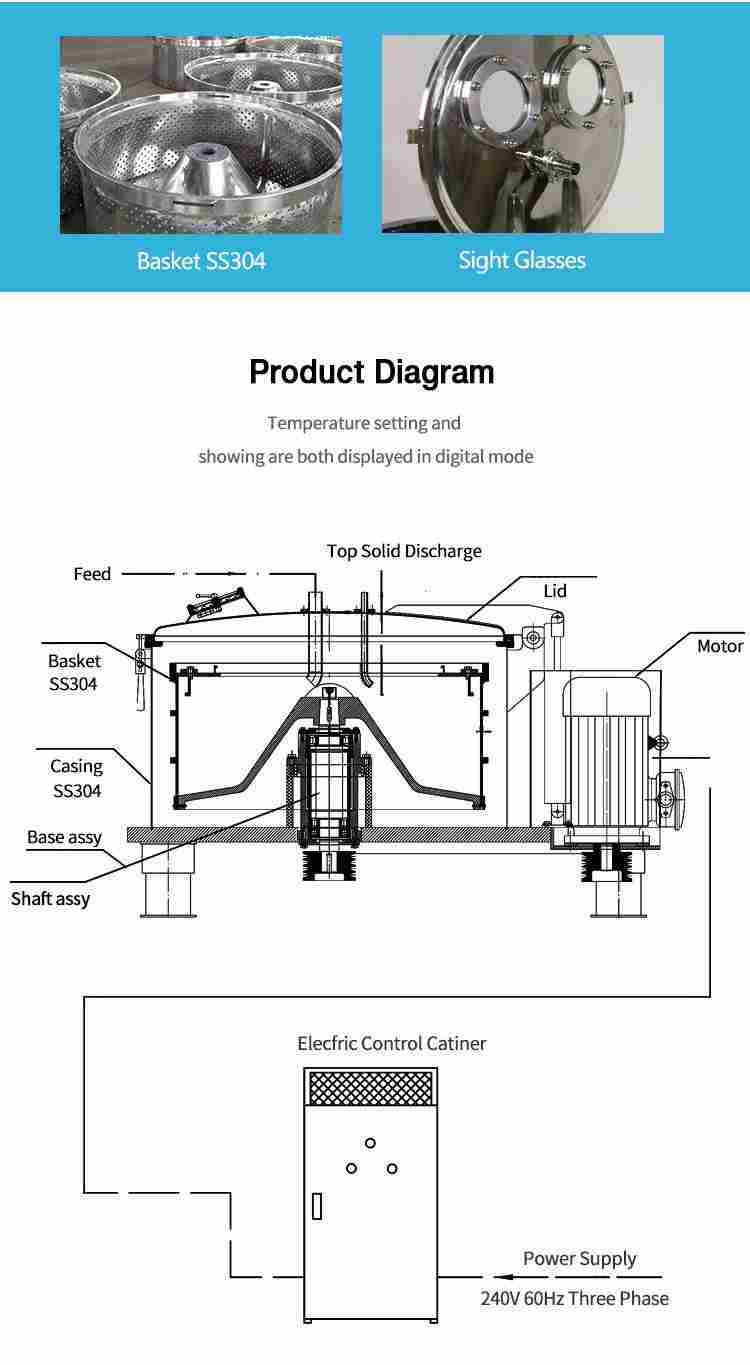

1. The parts in contact with the materials inside the centrifuge, the external structural parts and fasteners of the centrifuge are all made of stainless steel.

The inner and outer shell design of the bearing seat can be lifted vertically from the upper part, which is convenient for disassembly and maintenance, and the seal is reliable.

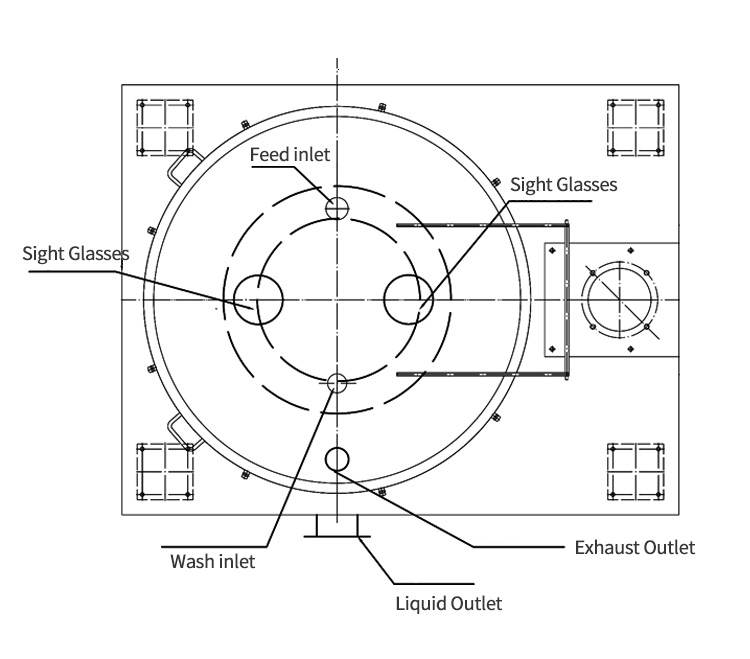

2. Airtight structure, the seal is made of silicon rubber or fluorine rubber, which can meet the requirements of sealing and explosion-proof, and is suitable for toxic, flammable and explosive occasions.

3. The machine cover is a spring-type large flip cover, and the seal is made of silicone rubber, which can meet the requirements of airtight and explosion-proof.

4. Equipped with a high-viscosity liquid damping shock absorber, which can eliminate vibration more effectively and simplify daily maintenance.

5. The product bag is unloaded, and the fine materials are discharged, which reduces the labor life and requires high production numbers. At the same time, it also avoids the pollution and scattering of the finished product caused by manual unloading.

6. The structure design is reasonable, and the shell is tightly designed with a large flip cover. The space between the centrifuge shell and the drum can be thoroughly cleaned.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

How to properly maintain the stainless steel centrifuge?

When using a stainless steel centrifuge, the weight of the material should not exceed the weight that the stainless steel centrifuge can withstand, and the material should be evenly placed in the correct place, so as not to reduce the service life of the stainless steel centrifuge due to overweight. Of course, we also need to refuel the centrifuge regularly, usually every 6 months. It is also necessary to check whether the internal equipment of the centrifuge is worn and loose. If the wear is serious, it should be replaced in time.

What should be paid attention to in the use of stainless steel centrifuge?

The stainless steel centrifuge should be placed on a very solid ground and equipped with dust-proof and moisture-proof equipment to ensure that the centrifuge chamber reaches a certain degree of vacuum and operates normally. Do not store any dangerous items near the stainless steel centrifuge. Choose a suitable rotor and control the speed of the rotor. The speed setting should not exceed the maximum speed.

Can the stainless steel centrifuge run continuously?

The running time of the stainless steel centrifuge should not exceed 60 minutes.

Mode | KDCM-10 | KDCM-30 | KDCM-50 | KDCM-100 |

Diameter ( mm) | 300 | 450 | 600 | 800 |

Capacity (L) | 5 | 20 | 40 | 100 |

Max Load (kg) | 7.5 | 30 | 60 | 135 |

Motor (kw) | 0.75 | 1.5 | 3 | 5.5 |

weight (kg) | 200 | 300 | 650 | 1600 |