Advantages of stainless steel centrifuge:

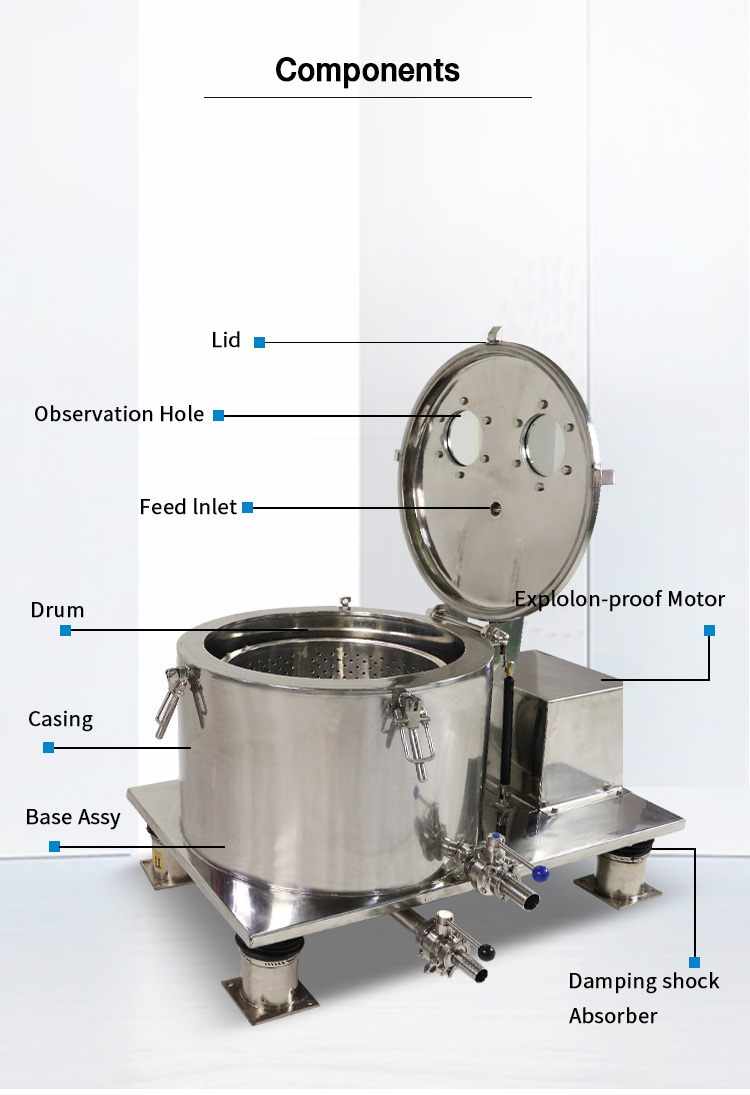

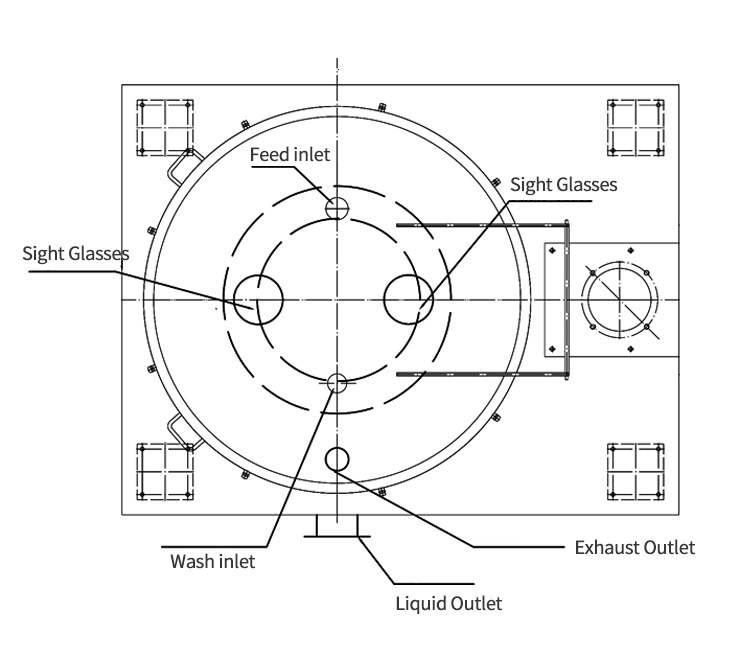

The stainless steel centrifuge has a reasonable structure design, which effectively eliminates sanitary dead corners. The structural parts are smooth and flat, and the surface is polished. The external structural parts, fasteners, and steel drums are all made of stainless steel. The shell is a flip type, which can thoroughly clean the space between the centrifuge shell and the drum compartment.

Features of stainless steel centrifuge:

1. Simple structure, convenient operation and maintenance.

2. Strong versatility and wide application range.

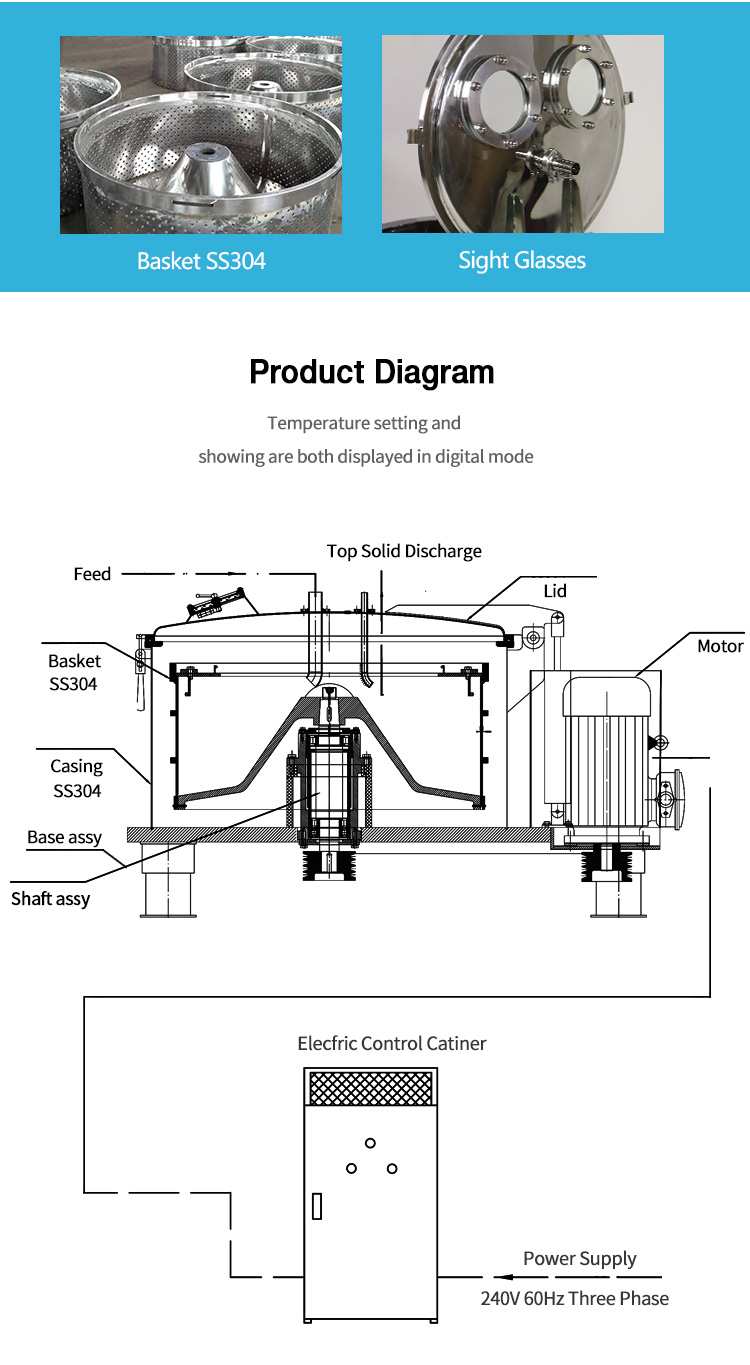

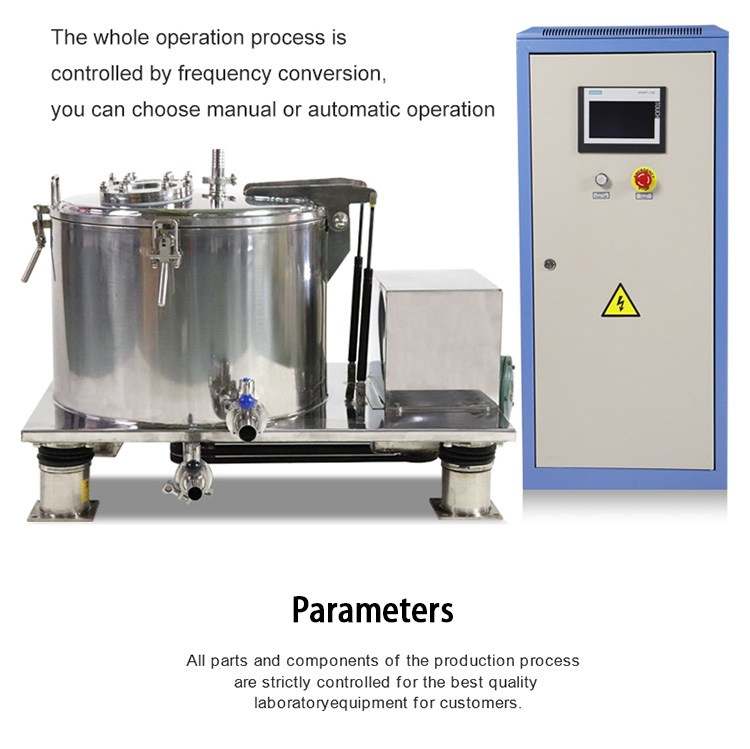

3. Adopt frequency conversion control, stable start, adjustable separation factor.

4. The machine wall is a flat structure, which not only lowers the center of gravity of the machine, and makes the machine need to run more smoothly, but also the flat-type machine base can be used as an operating flat. The operation is more convenient.

5. The material particles are not easy to be broken.

6. The structure design is reasonable, and the shell is tightly designed with a large flip cover. The space between the centrifuge shell and the drum can be thoroughly cleaned.

7. The base and the casing are integrally welded, with high load-bearing strength.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

What should be paid attention to in the use of stainless steel centrifuge?

The stainless steel centrifuge should be placed on a very solid ground and equipped with dust-proof and moisture-proof equipment to ensure that the centrifuge chamber reaches a certain degree of vacuum and operates normally. Do not store any dangerous items near the stainless steel centrifuge. Choose a suitable rotor and control the speed of the rotor. The speed setting should not exceed the maximum speed.

Under what circumstances should the stainless steel centrifuge reduce the maximum speed of the rotor?

When the rotor's operating time and number of operations reach the specified life; when the rotor is locally damaged or slightly corroded in the pipe hole; when the average density of the sample exceeds 1.2g/cm3; when the rotor is exposed to high temperatures

Is the stainless steel centrifuge resistant to acid and alkali?

Of course, the main characteristic of stainless steel is acid and alkali resistance.

Mode | KDCM-10 | KDCM-30 | KDCM-50 | KDCM-100 |

Diameter ( mm) | 300 | 450 | 600 | 800 |

Capacity (L) | 5 | 20 | 40 | 100 |

Max Load (kg) | 7.5 | 30 | 60 | 135 |

Motor (kw) | 0.75 | 1.5 | 3 | 5.5 |

weight (kg) | 200 | 300 | 650 | 1600 |