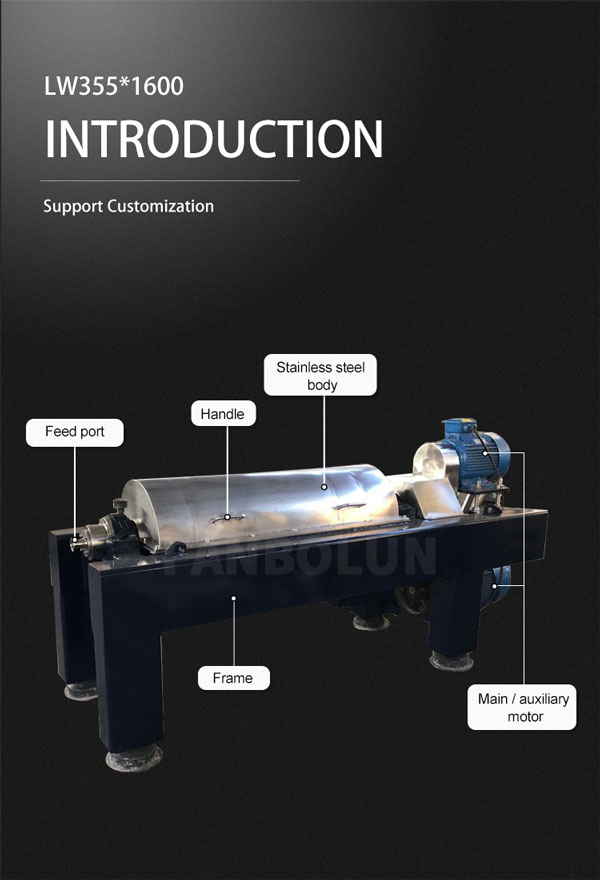

Product Description:

The working precept of the decanter centrifuge is as follows: the drum and the screw rotate in the identical direction and excessive speed at a sure differential speed, the fabric is continuously launched into the inner cylinder of the feeding screw from the feeding pipe, and enters the drum after acceleration. The strong section deposits on the drum wall to form a sediment layer. The feeding screw continuously pushes the deposited solids to the conical finish of the drum and discharges them out of the machine via the slag discharge port. The lighter liquid part materials varieties an internal liquid ring, which repeatedly overflows the bowl from the overflow port on the giant finish of the bowl, and is discharged out of the machine by way of the drain port.

This machine can repeatedly feed, separate, wash and unload at full velocity. It has the characteristics of compact construction, steady operation, stable operation, robust adaptability, massive manufacturing capacity and convenient upkeep. It is appropriate for separating suspensions containing solids with a particle size higher than 0.005mm and a concentration vary of 2-40%. Widely utilized in chemical, light trade, pharmaceutical, food, environmental protection and other industries.We are one of the most capable decanter centrifuge manufacturer in China.

Decanter Centrifuge Working Principle:

Feeding introduction: The slurry is fed into the machine through the axial feed tube, which injects it into the conveyor. The tube conveys the slurry to the center of the conveyor feed chamber.

Acceleration / Dispersal: The injected slurry strikes against an accelerator within the conveyor feed zone. This action accelerates the flow outward through the feed ports into the bowl, forming a 'pond.'

Separation: The solids, being of upper density, displace the liquid and settle to the bowl's wall. The conveyor constantly scrolls the solids up the angled conical part (beach).

Sludge Discharge: The flights push the separated sludge up the bowl's conical half (beach). The solids exit the bowl through 360° solids discharge ports situated at the rear finish.

Fluid Discharge: The clarified liquid rises to the pond's surface and flows over the dams positioned in the entrance bowl hub. At this level, the liquid discharges from the bowl.

Advantages Of Decanter Centrifuge:

Decanters compete with other separation technologies such as filter presses, screw presses, etc.Though all these equipment have advantages, decanters have some specific benefits. These advantages are due to the decanter centrifuge price being a mechanical separator.All the other applied sciences use media separation, which has inherent drawbacks.

The following is an inventory of benefits of decanter centrifuge for sale over filtration strategies.

1. Process Adaptability:

Decanter centrifuge cost can easily handle product variations. They can produce consistent separation results even with various flow rates. These centrifuges can deal with process fluid combine variations with out ultimate product degradation.

2. Vapor Tight Design:

The fundamental design of decanters features a rotating bowl in an enclosed chamber. This design prevents odors and different undesirable fumes, gases from contaminating the working area.

3. Low Labor Costs:

Fluid separation by way of a decanter is virtually an automated course of. This process requires minimal guide service of attendance, thereby reducing related labor prices.

4. Reduced Operating Cost:

Since solely put on components are replaceable in decanter centrifuge price, it minimizes the long-term operating prices. Filter media want fixed replacement in other separation methods.

5. Long Service Life:

Robust design and development are main features of decanter centrifuges. Besides, high-quality materials of construction helps decanters perform with reliability for extended durations.

6. Easy and Quick Installation:

Decanter centrifuge methods are self-contained and are thus simple to install. The pace and ease of commissioning permit them to be productive in brief intervals.

7. Wide Range of Particle Separation:

The decanter separates particle size vary from 1 Micron to fifteen mm or larger. This capacity provides decanters a major advantage over media filters with fixed apertures.

8. Easy Adjustments for Desired Separation Phase:

The decanter centrifuge for sale user can adjust sludge dryness or centrate clarity rapidly and easily. This ease of section high quality adjustment is an additional advantage that's lacking in filtration gear.

Applications Of Decanter Centrifuge:

1. The main purpose of a decanter centrifuge is to separate a large amount of solids from a liquid on a continuous basis. They are also used in trade to scrub and dry bulk solids, similar to polystyrene beads, to make clear liquids and focused solids.

2. Mineral oil industry: Used in petrochemical/petroleum industry for refining, dewatering, oil drilling correctly, lubricant additives, waste oil stream recovery, etc.purification of fuel oil and lubricating oil for ship main engine, land diesel engine, power station.

3. Used for industrial and biological wastewater treatment industry and municipal sewage, washing water cleaning

4. Vegetable oil industry: purification and clarification of palm oil, degumming, soap removal, dehydration and dewaxing of vegetable oil refining; at high temperature: used for oil clarification and improvement of oil quality, suitable for fried foods (such as potato chips, etc.) industry.

5. Beverage products industry: clarification of beer, fruit juice, beverages, etc., extraction of vegetable protein, wastewater treatment, etc.; clarification, purification, separation and extraction of bioengineering fermentation broth.

6. Pharmaceutical industry: purification or clarification in the extraction process of biochemical pharmaceuticals, clarification of traditional Chinese medicines; extraction of vitamins, etc., separation of liquid-liquid-solid three-phase mixtures.

7. Chemical industry: purification or clarification of chemical raw materials; liquid-solid separation or liquid-liquid-solid three-phase separation.

8. Lanolin industry: extraction and purification of lanolin from wool scouring sewage; concentration and separation of fish oil, etc.

Model | LW355*1600 |

Main motor power (kW) | 18.5 |

Auxiliary motor power (kW) | 7.5 |

Drum speed (R/min) | ≤4000 |

Separation factor (g) | 3200 |

Differential speed (R/min) | 2-25 |

Drum inner diameter (mm) | 355 |

Drum length (mm) | 1600 |

Dimensions (mm) | 3500*840*118 |

Weight (kg) | 1800 |