Advantages of short-path distillation:

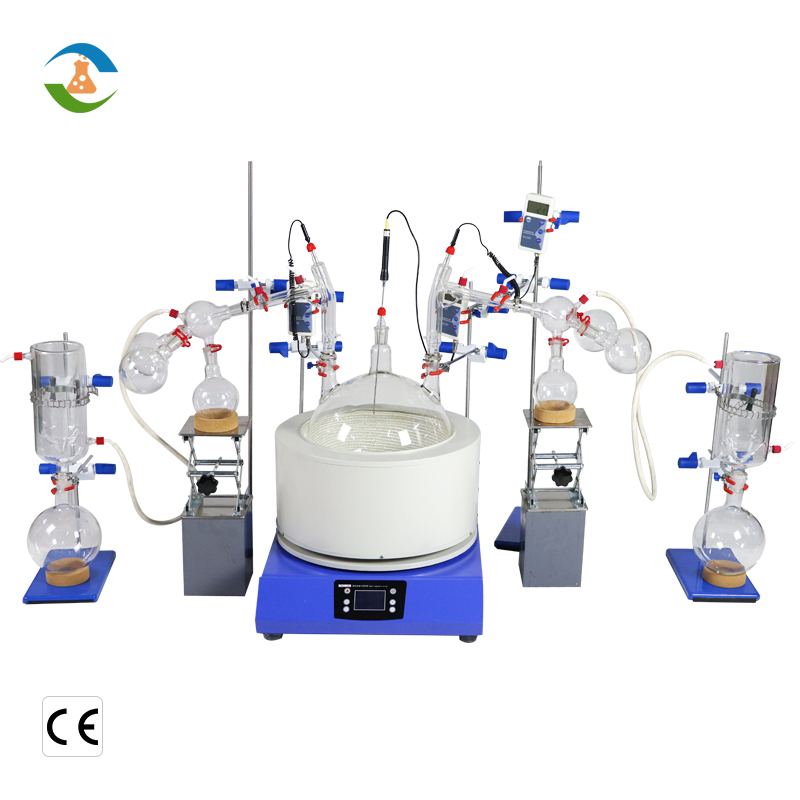

The SPD-2L short-path distillation kit is made of high borosilicate glass and stainless steel, which has good corrosion resistance. As a laboratory distillation equipment, it is small in size, high in evaporation rate and easy to operate.

Features of short path distillation:

1. No boiling and bubbling phenomenon. Molecular distillation is the free evaporation process on the surface of the liquid layer. It is carried out at low pressure, there is no dissolved air in the liquid 2, so the whole liquid will not boil, and there will be no bubbles during the distillation;

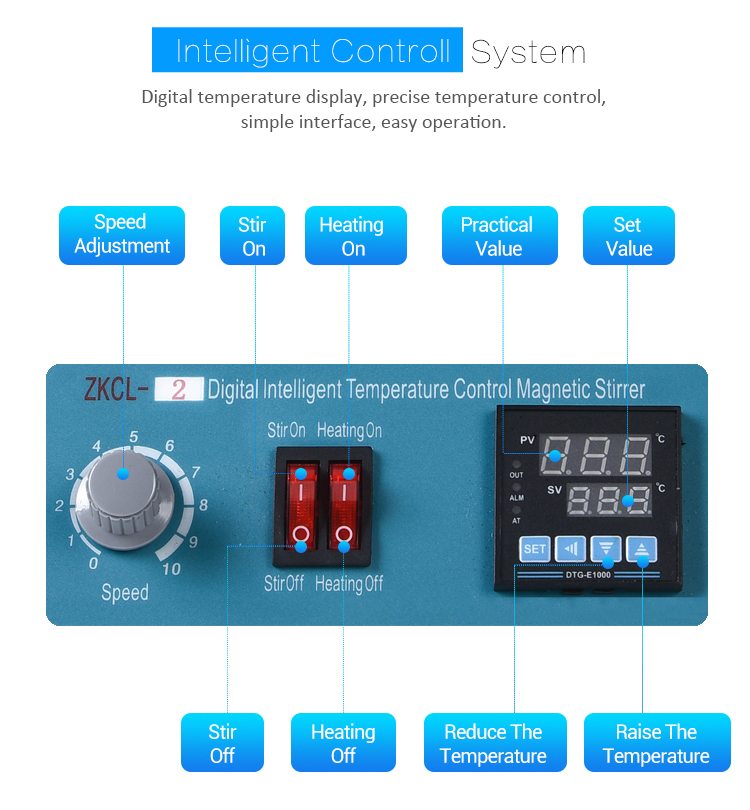

3. Temperature adjustable design, precise temperature control.

4. 304 stainless steel bracket, firm support.

5. Intelligent speed adjustment, stable rotation.

6. Intelligent temperature control, heating accuracy is ±1°C.

7. The degree of separation is high, molecular distillation can separate conventional substances that are difficult to separate;

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

Operation process of short-path distillation:

1. Install the feeder (screw the sampler clockwise), the first, second, and third-stage receiving bottle, and turn on the cooling water circulation button;

2. Open the rotor of the film wiper and adjust to the specified speed (not exceeding 400 r/min);

3. Turn on the vacuum pump after the liquid nitrogen reaches the required level (not less than 1/2 of the volume of the condensing column);

4. When the pressure no longer drops, adjust the vacuum pump fine-tuning valve (not less than 0.5 mbar);

5. After the pressure is adjusted in place, turn the valve of the sampler counterclockwise to adjust the feeding speed;

6. During the operation of the equipment, the liquid can be added at any time through the feeder;

7. When the liquid volume in the feeder is about 50 ml and no more feeding, turn off the vacuum pump, call back the fine-tuning valve, wait for 10 minutes when the pressure is displayed to 1000 mbar, turn off the heater when the pressure is exhausted, and remove it The feeder, pour out the remaining liquid, and replace it with absolute ethanol;

8. Replace the next and second level receiving bottles, install empty bottles, unscrew the feeder, slowly inject absolute ethanol, and use the residual heat to clean the equipment;

9. After cleaning, turn off the cooling water and rotor, take off the feeder and receiving bottle and wash it separately;

10. Turn off the power and clean the countertop.

What are the applications of short-path distillation?

As a hot product of our company, short-path distillation is committed to high efficiency and low cost. At the same time, the short-path distillation device is widely used in pharmaceutical, laboratory fractionation and purification, food and beverage, essential oil and other industries.

What materials are mainly used in short-path distillation equipment?

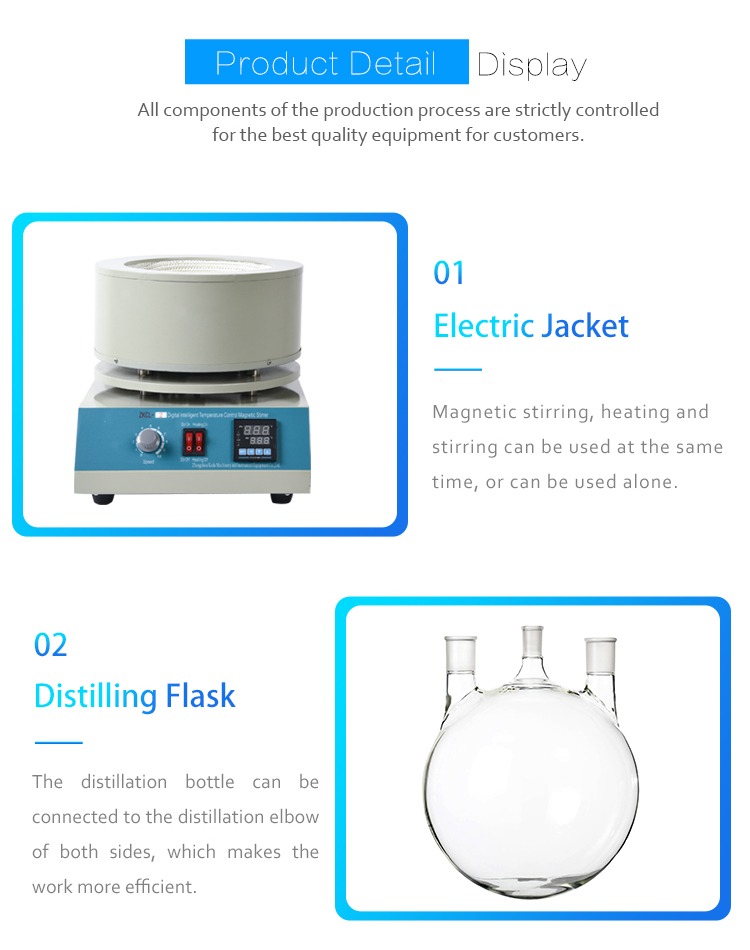

The main raw materials for the production of short-path distillation kits are borosilicate glass, polytetrafluoroethylene, 304 stainless steel and other materials. They all have good chemical resistance and are very good laboratory distillation equipment.

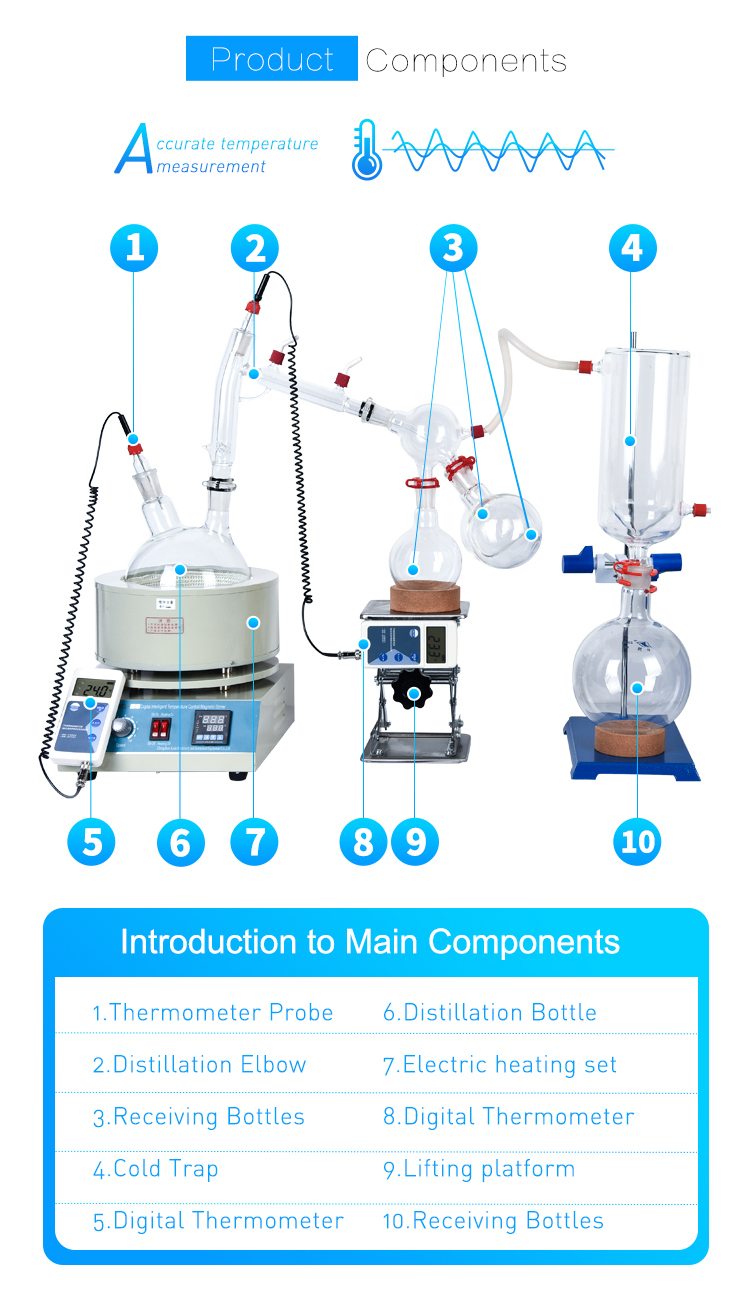

Model | Parts name | Parts number |

2L short path distillation | 2000 ml Digital Heating Mantle | 1 |

2000 ml 2 Neck Boiling Flask | 1 | |

Short Path Distillation Head | 1 | |

Cow Receiver | 1 | |

500 ml Round Bottom Flasks | 3 | |

Plastic Keck Clips | 7 | |

Cast Iron Stand | 1 | |

Metal Three Finger Clamp | 1 |