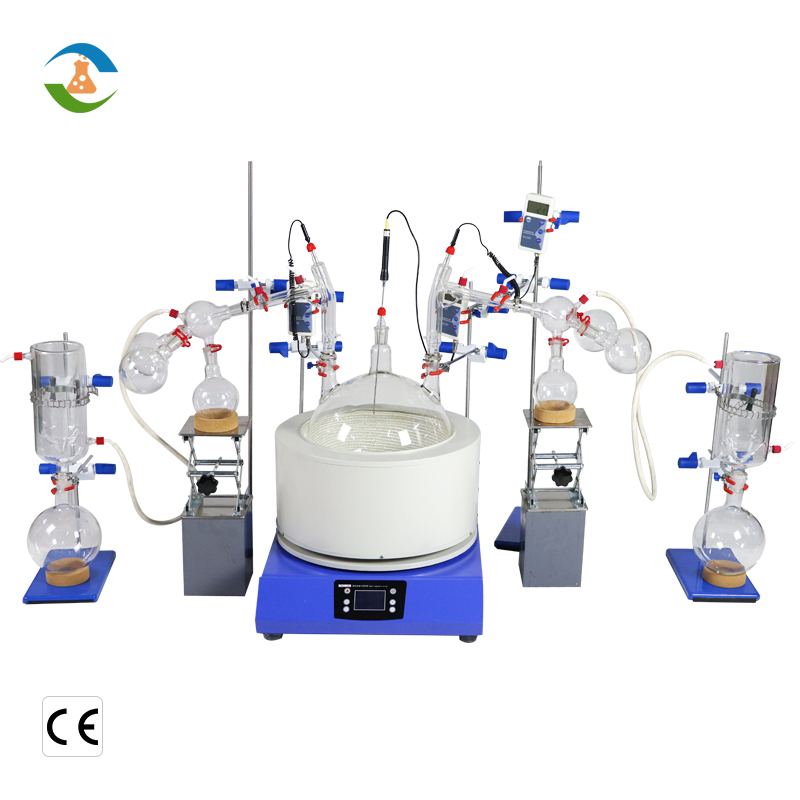

Advantages of short-path distillation:

As a hot product of our company, short-path distillation is committed to high efficiency and low cost. At the same time, the short-path distillation device is widely used in pharmaceutical, laboratory fractionation and purification, food and beverage, essential oil and other industries.

Features of short path distillation:

1. The structure is simple and does not take up space.

2. Flange connection between interfaces, good sealing.

3. Small footprint and easy operation.

4. High-precision transmission and mechanical seal design ensure long-term stable operation of the equipment.

5. The surface of the cylinder is smooth and not easy to stick.

6. Effectively remove organic solvents, odors and other liquid substances, which is a very effective method for desolventizing liquids after solvent extraction;

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

Circulating water type multifunctional vacuum pump

Diaphragm Vacuum Pump

Rotary vane vacuum pump

Low temperature coolant circulation pump

Low temperature constant temperature reaction tank

FAQ:

What are the applicable scopes of short-path distillation?

1. Fine chemicals: such as aromatic oil purification, polymer intermediate purification, lanolin extraction, etc.;

2. Medical field: such as extracting natural vitamin AE, synthetic amino acid and glucose derivatives;

3. Food industry: such as refining fish oil, deacidification, refining higher alcohols, and separating mixed oils;

4. Other fields: petroleum industry, chemical industry, environmental protection.

What is short-path distillation?

The driving force of the steam flow is the pressure difference between the boiling film and the condensing surface, and a small pressure drop will cause the steam to flow. It operates under 1mbar and requires a short distance between the boiling surface and the condensing surface. A distiller made according to this principle is called a short-path distiller.

What are the types of film wipers for short-path distillation and how to choose?

Rolling film type, sliding film scraping type, hinge scraping film type, suitable film scraper can be selected according to the viscosity and processing properties of the material.

Model | Parts name | Parts number |

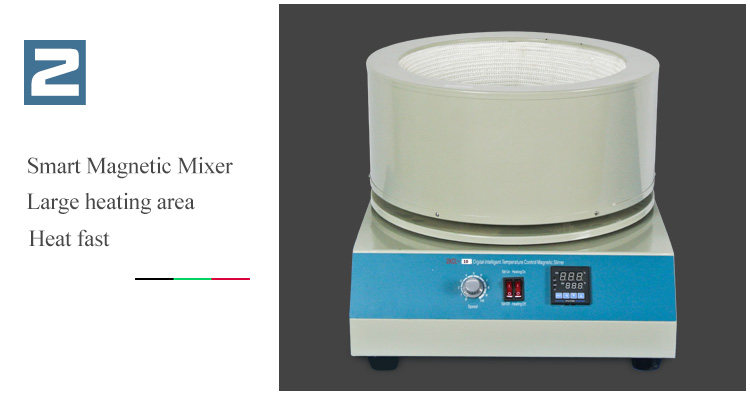

10L short path distillation | 10000 ml Digital Heating Mantle | 1 |

10000 ml 2 Neck Boiling Flask | 1 | |

Short Path Distillation Head | 1 | |

Cow Receiver | 1 | |

1000 ml Round Bottom Flasks | 3 | |

Plastic Keck Clips | 7 | |

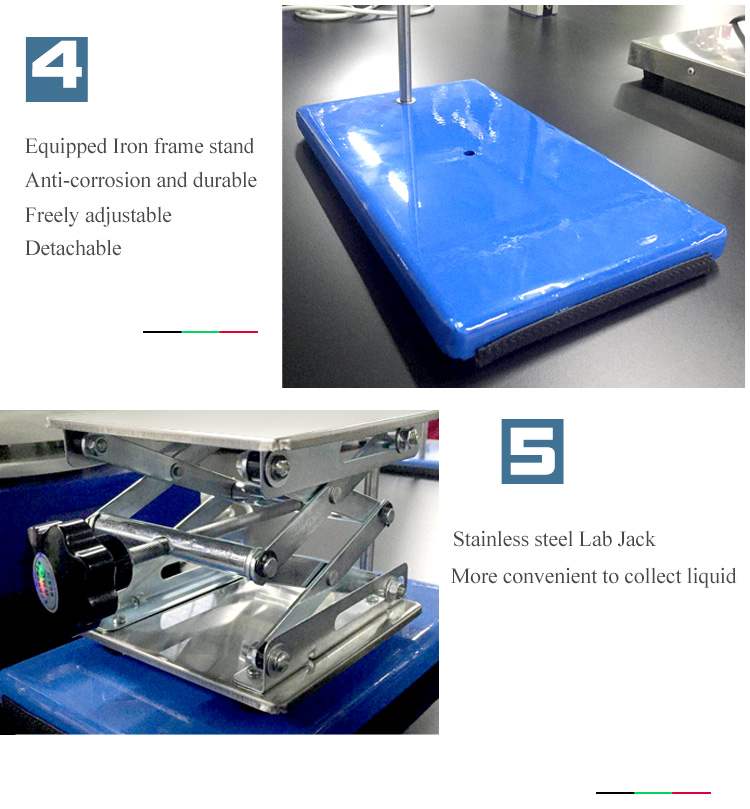

Cast Iron Stand | 2 | |

Metal Three Finger Clamp | 1 | |

Cold trap | 1 | |

PTFE magnetic stirring bar | 1 | |

Lifting platform | 1 | |

backing ring | 1 |