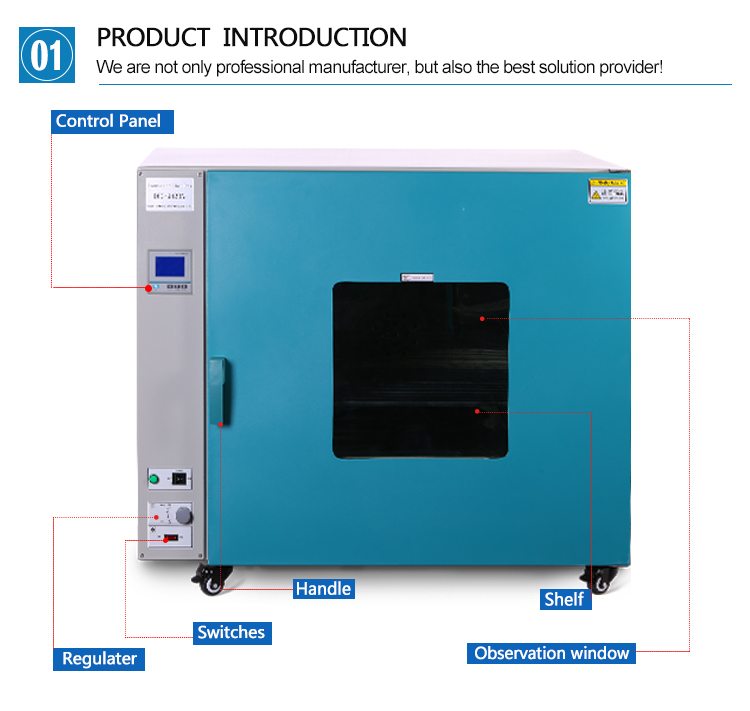

Advantages of blast drying oven:

The blast drying oven is small in size and easy to move in experiments. It is used in industrial and mining enterprises, biopharmaceuticals, food processing, scientific research, medical units and various laboratories. The materials can be dried, baked, melted wax, disinfected, and sterilized.

Features of blast drying oven:

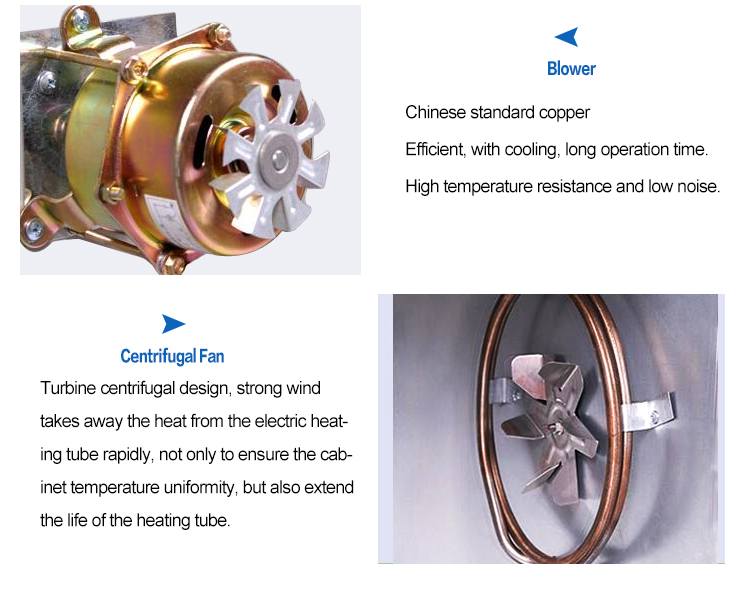

1. High-quality stainless steel electric heating tube, uniform heating and long service life.

2. The silicone door sealing ring is formed as a whole to ensure the high vacuum of the studio.

3. The temperature control range can reach RT+10~250℃.

4. It is convenient to observe the reaction of materials in the working room.

5. The working room is made of stainless steel plate, which is durable.

6. The set temperature has a protective device, the temperature is controlled by a microcomputer temperature controller, and the temperature is accurately controlled

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

Diaphragm Vacuum Pump

Rotary vane vacuum pump

FAQ:

What is the reason why the temperature of the blast drying oven does not rise?

The set temperature is too low, the wiring of the thermometer output circuit is closed, the temperature controller has no output signal is bad, the heater is damaged, the timer is activated, or the setting is incorrect.

Product Usage:

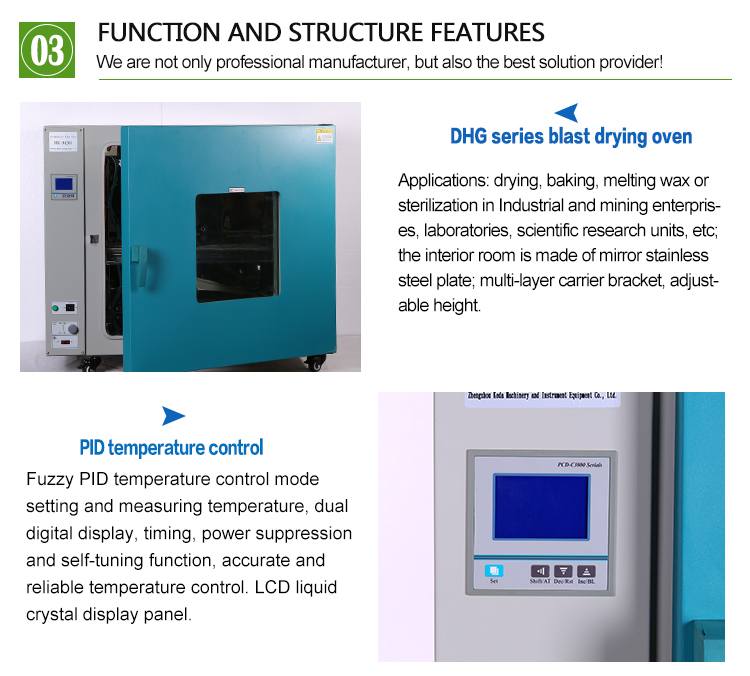

The blast drying oven is used for drying, baking, wax melting, and sterilization for industrial and mining enterprises, laboratories, scientific research institutions, testing institutions, and universities.

What is the principle of the blast drying oven?

Hot air is blown out by a circulating fan to ensure the temperature balance in the box.

What is the principle of the blast drying oven?

When the hot air in the drying room heats the material, the moisture will become water vapor and mixed into the hot air. The air in the drying room is convectively circulated through the fan, and then the hot air with water vapor is discharged through the exhaust hole, and the air intake hole draws The air outside the drying room enters the drying room, and the moisture is also taken out of the drying room through the continuous exchange of air inside and outside the drying room, so as to achieve the purpose of drying.

Model | DHG-9420A |

Power Supply | 220V/50Hz |

Shell Material | Spray-paint Anti-corrosion |

Liner Material | 304 Stainless Steel |

Temp. Range | RT+10~250°C |

Temp. Stability | ±1.0°C |

Temp.Analysis | 0.1°C |

Working Temp. | +5~40°C |

Input Power (W) | 3500 |

Chamber Capacity (L) | 393 |

Inner Dimension (W*D*H, mm) | 750*750*700 |

Overall Dimension (W*D*H, mm) | 1050*950*920 |

Shelves (Pcs) | 3 |

Time Range | 1~9999 min |

Optional Configuration | EX |