Advantages of blast drying oven:

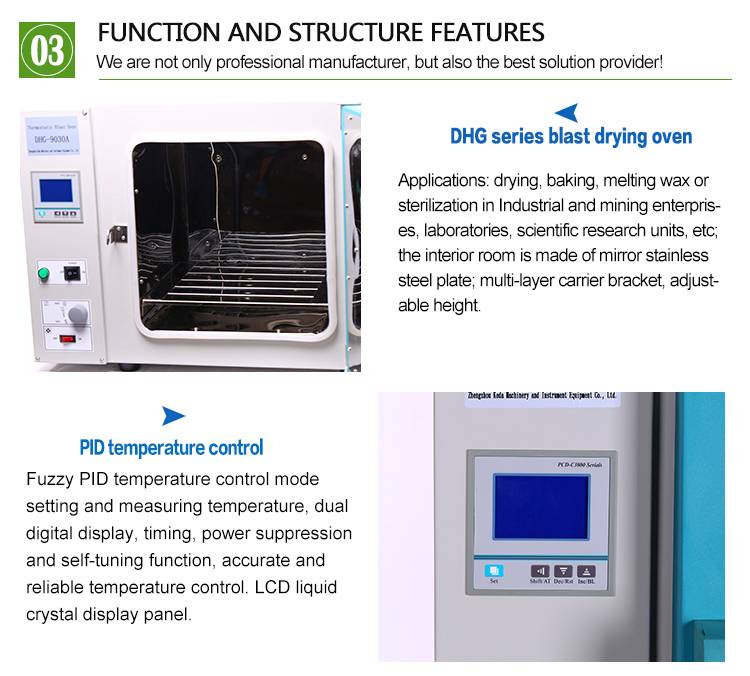

Blast drying oven is one of the most commonly used drying equipment, widely used in industrial and mining enterprise laboratories, medical and health research institutes, for drying, baking, wax melting, sterilization, curing and other reactions.

Features of blast drying oven:

1. Double-layer tempered glass door, two layers inside and outside, beautiful and generous.

2.1-9999min timing range.

3. The use of a new type of synthetic silicon sealing strip, can run at high temperature for a long time, has a long service life and is easy to replace.

4. The box body is made of high-quality steel plate with beautiful appearance.

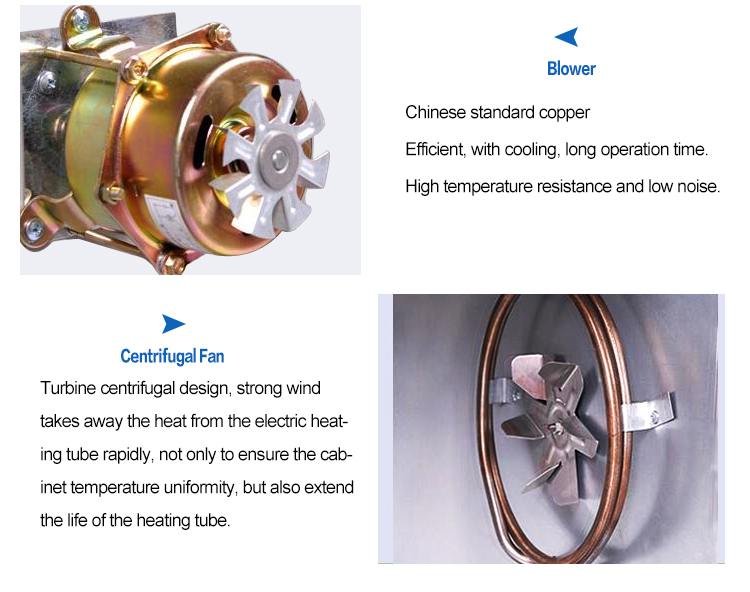

5. The temperature is more uniform and the materials can be fully reacted.

6. Over temperature protection, sensor open/short circuit protection, automatic alarm

7. The air inlet can be opened and closed freely, the air duct structure is reasonable, and the temperature uniformity in the working room is good

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

Diaphragm Vacuum Pump

Rotary vane vacuum pump

FAQ:

What is the principle of the blast drying oven?

When the hot air in the drying room heats the material, the moisture will become water vapor and mixed into the hot air. The air in the drying room is convectively circulated through the fan, and then the hot air with water vapor is discharged through the exhaust hole, and the air intake hole draws The air outside the drying room enters the drying room, and the moisture is also taken out of the drying room through the continuous exchange of air inside and outside the drying room, so as to achieve the purpose of drying.

Product use:

The blast drying oven is used for drying, baking, wax melting, and sterilization for industrial and mining enterprises, laboratories, scientific research institutions, testing institutions, and universities.

What are the advantages of the blast drying oven?

The electric heating method is used to carry out the blast circulation drying test. The hot air is blown out by the circulation fan to form convection in the box, thereby ensuring the temperature balance in the box, so that the items can be dried quickly. It is mostly used in chemicals, medicine, casting, automobiles, food, machinery And so on in various industries. The heating speed is fast, the uniformity is high, and it is suitable for most industries.

Which vacuum pump can be selected for the blast drying box?

The blast drying box produced by our company can be equipped with rotary vane vacuum pump, diaphragm pump and circulating water vacuum pump. Please contact us for specifications.

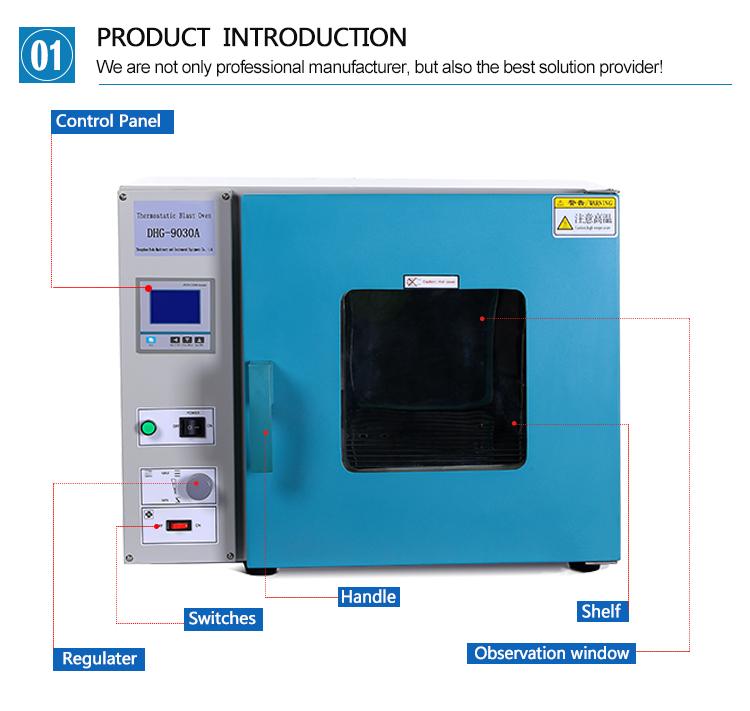

Model | DHG-9030A |

Power Supply | 220V/50Hz |

Shell Material | Spray-paint Anti-corrosion |

Liner Material | 304 Stainless Steel |

Temp. Range | RT+10~250°C |

Temp. Stability | ±1.0°C |

Temp.Analysis | 0.1°C |

Working Temp. | +5~40°C |

Input Power (W) | 850 |

Chamber Capacity (L) | 40 |

Inner Dimension (W*D*H, mm) | 340*340*340 |

Overall Dimension (W*D*H, mm) | 630*600*500 |

Shelves (Pcs) | 1 |

Time Range | 1~9999 min |

Optional Configuration | EX |