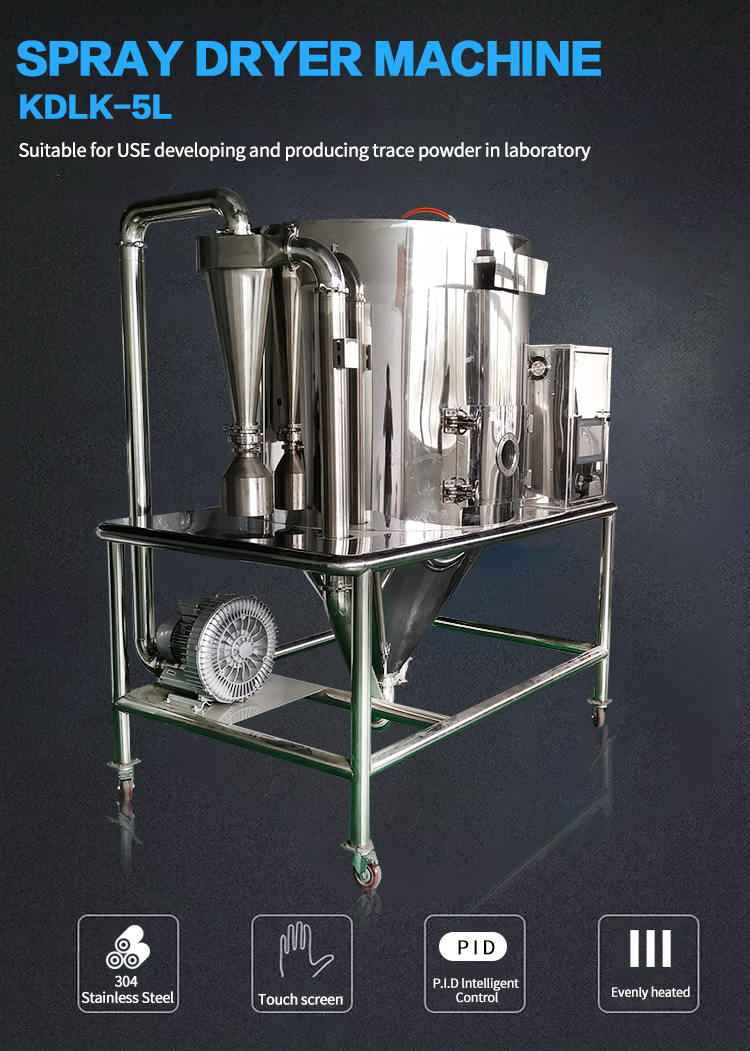

Advantages of spray dryer:

The laboratory spray dryer produced by our company is made of 304 stainless steel. It adopts two-stage heating and can be heated to the set temperature in one minute. It can start the experiment faster. Compared with other spray dryers on the market, it has a lower The powder moisture content.

Features of spray dryer:

1. The noise is very low, less than 60db, which meets the laboratory noise standard.

2.18kw high power heating, faster heating speed.

3. Bipolar spiral hot air distributor, hot air is more even.

4. The high-efficiency volute cyclone separator is used for material recovery, and the recovery speed is faster.

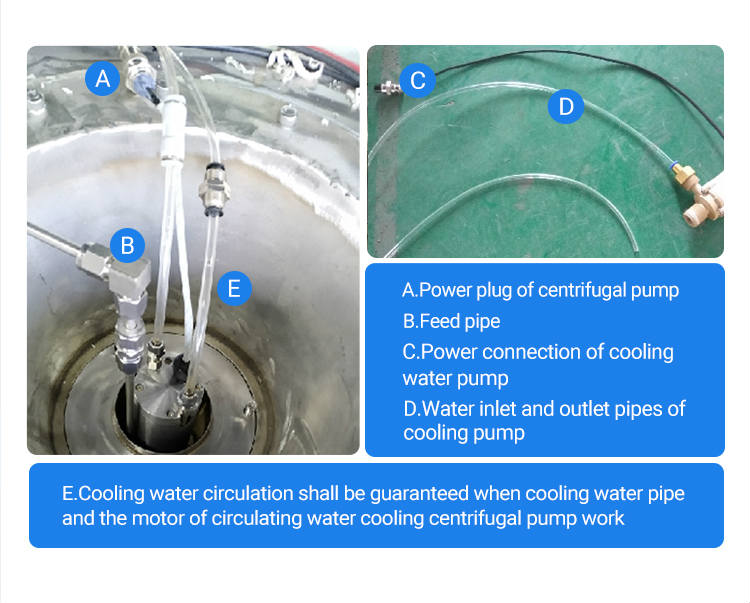

5. Cooling water pipe, circulating water cooling centrifugal pump motor, it is necessary to ensure that there is circulating cooling water during work.

6. All components of the whole machine are integrally formed, all 304 stainless steel, anti-corrosion and easy to clean.

7. The operating noise of the whole machine is low, less than 50 decibels, and it is not noisy to use in the laboratory.

8. Use the touch screen to display operation, control temperature, air flow, air pressure, pump speed and deblocking frequency, etc.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

What is a collection system for spray drying?

The collector is a classic powder collector, widely used by spray dryer systems. Its structure and shape directly affect the collection rate of powder, and it plays an important role in the spray dryer. For the spray dryer system, the performance of the collector is often considered through observations of actual operations and experimental results.

What is the working principle of spray drying?

After filtering and heating, the air enters the air distributor on the top of the dryer, and the hot air enters the drying chamber evenly in a spiral shape. The material liquid passes through the high-speed centrifugal atomizer at the top of the tower, and (rotating) sprays into very fine misty liquid beads, which can be dried into finished products in a very short time in co-current contact with hot air. The finished product is continuously output from the bottom of the drying tower and the cyclone separator, and the waste gas is evacuated by the induced draft fan.

What are the application areas of spray drying?

Beverages, flavors and colors, milk and egg products, plant and vegetable extracts, pharmaceutical synthesis, heat-sensitive plastics, polymers and resins, fragrances, blood products, superconductors, biochemical products, dyes, soaps and detergents, food bonding Agents, oxides, bone meal and tooth powder, etc.

Material: Solution (include some suspension liquids) |

Max. water evaporation capacity of host machine: About 6L/h |

Inlet air temperature: From room temperature to 330℃ |

Outlet air temperature: From room temperature to 140℃ |

Heating method: Electrical heating |

Drying method: Centrifugal atomization |

Equipment material: 304 stainless steel |

Installation site: Indoor Working voltage: 380V 50-60HZ |

Floor area (length, width and height): 2.0m*1.3m*2.15m |