Advantages of spray dryer:

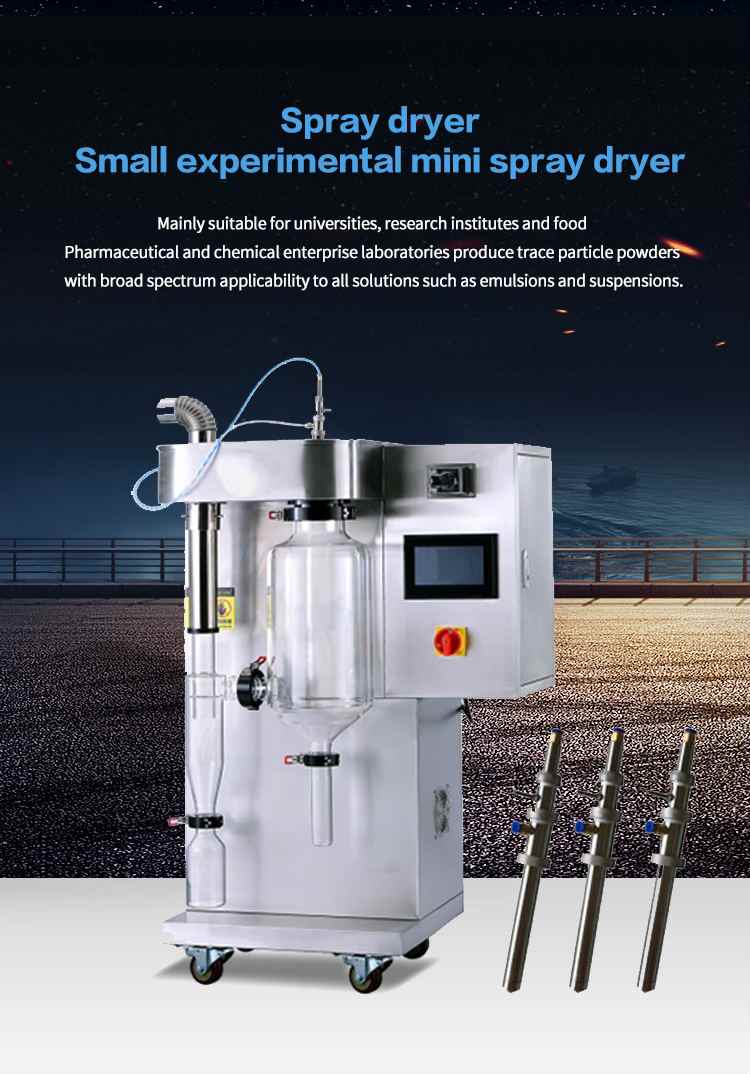

Spray dryers (small spray dryers) are mainly used in universities, research institutes and laboratories of food, medicine and chemical companies to produce micro-particle powders, and have wide applicability to all solutions such as emulsions and suspensions. To

Features of spray dryer:

1. The drying speed is fast, the surface area of the material liquid is greatly increased after atomization, and it can evaporate in an instant in the hot air flow. With 95%-98% moisture, it only takes a few seconds to complete the drying process, which is especially suitable for drying heat-sensitive materials.

2. It has good uniformity, fluidity and solubility, and the product has high purity and good quality.

3. The production process is simplified and the operation and control are convenient. For liquids with a moisture content of 40-60% (up to 90% for special materials), it can be dried into powder products at one time.

4. Fast drying speed, generally only 5-15 seconds, with instant drying characteristics.

5. The particle size of the finished dry powder after drying is relatively uniform, and more than 95% of the dry powder is in the same particle size range.

6. With protection function, the heater cannot be started if the fan is not started.

7. The temperature control adopts real-time regulation PID constant temperature control technology, and the temperature control is accurate.

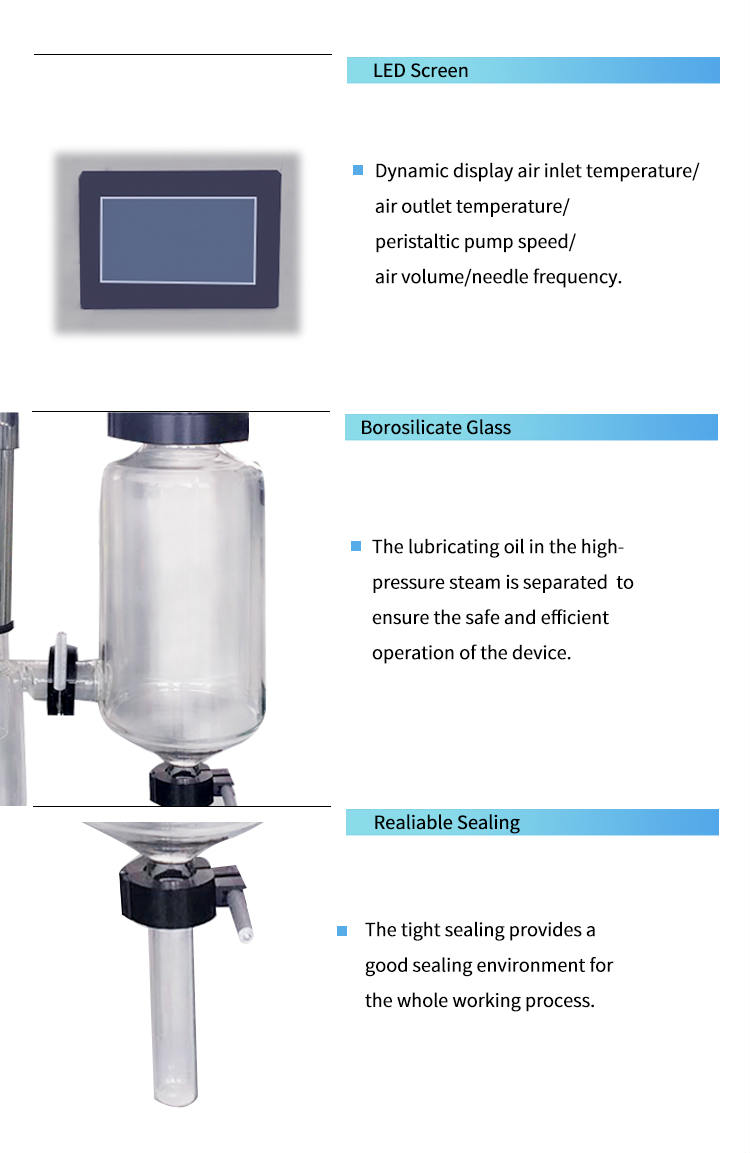

8. The spray, drying chamber and collection device are made of transparent high temperature resistant high borosilicate glass, so that the spray drying process can be carried out in a pollution-free and stable environment.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

What are the main components of spray drying?

It is mainly composed of hot air circulation system, liquid atomization system and collection system.

What is the hot air circulation system for spray drying?

In the process of spray drying, the hot air circulation system is the main power and carrier for drying, collection, and steam discharge. Adopt negative pressure suction method to make hot air circulate in the system. Its advantages are: the hot air is controlled in the system, no leakage, will not affect the experimental environment, so that the experimental staff can work in a clean experimental environment.

What is a spray drying liquid atomization system?

In the spray dryer system, the atomizing nozzle is a crucial element, and there are usually four nozzles with 0.7mm, 1.0mm, 1.4mm, and 2.0mm apertures to choose from. According to different materials and solutions, the selection of nozzles should be consulted with product experts or selected after experiments. The experimental process of spray drying should achieve a complete set of process methods for the successful drying of a certain material. Each experimental parameter is an integral part of the whole process method.

Inlet air temperature: | Room temperature to 300°C |

Outlet temperature: | Room temperature to 140℃ |

Water evaporation capacity : | 0-2000ml/h |

Stainless steel nozzle: | Nozzle diameter Φ0.75mm |

Display: | 7-inch LCD touch operation display |

Real-time temperature control: | Error ±1℃ |

Real-time display temp. accuracy: | 0.1℃ |

Fan: | 0.75kW (aluminum alloy supercharged) |

Maximum drying air volume: | 105m³/h |

Inverter power: | 0.75kW |

Air compressor: | 0.55kW (oil-free) |

Whole machine power: | 2.2kW/4.4kW/8.8kW 220V |

Dimensions: | 650×500×1500mm |