Our rotary evaporator is usually used with a vacuum pump, and we provide supporting equipment for the rotary evaporator. Generally speaking, the vacuum pumps used in conjunction with rotary evaporators include circulating water vacuum pumps, rotary vane vacuum pumps, and diaphragm vacuum pumps.

The rotary evaporator is mainly used for distillation and extraction, and the rotary evaporator is usually used under vacuum. Therefore, it must be matched with a vacuum pump to achieve rapid distillation. But there are many types of vacuum pumps. Which vacuum pump is suitable for use with a rotary evaporator?

Vacuum pumps suitable for rotary evaporators:

Generally speaking, the three more suitable types are circulating water vacuum pumps, rotary vane vacuum pumps, and diaphragm vacuum pumps. These three vacuum pumps are commonly used to match glass reactors and rotary evaporators. Among them, circulating water vacuum pumps are divided into two types: desktop and vertical. The 2XZ series are commonly used in rotary vane vacuum pumps, while diaphragm vacuum pumps have corrosion resistance and can be used for corrosive solvents.

Circulating water vacuum pump

It is a new type of multi-purpose vacuum pump designed based on circulating water as the working fluid and the working principle of generating negative pressure by fluid jet injection. It is not only a vacuum pumping device, but also provides circulating cooling water to the reaction device. The pump has the characteristics of no oil, no pollution, corrosion resistance, low noise, convenience and flexibility. It adopts anti-corrosion movement or stainless steel movement, one machine can be used for multiple purposes, with a larger space, a vertical type can be used, and a small space can be used as a desktop type.

Rotary vane vacuum pump

The rotary vane vacuum pump adopts a double-stage high-speed direct-connected structure rotary vane, which is one of the basic equipment used to extract gas from a sealed container. The pump cavity is equipped with a rotor, and there is a rotary vane in the rotor slot. When the rotor drives the rotary vane to rotate, the rotary vane is close to the cavity wall to separate the inlet and exhaust ports, and the volume of the inlet cavity is periodically enlarged. Inhale, the volume of the exhaust chamber is periodically reduced to compress the gas, push the exhaust valve to exhaust, and obtain a vacuum. It has the characteristics of high speed, small appearance, compact structure, and convenient fluidity.

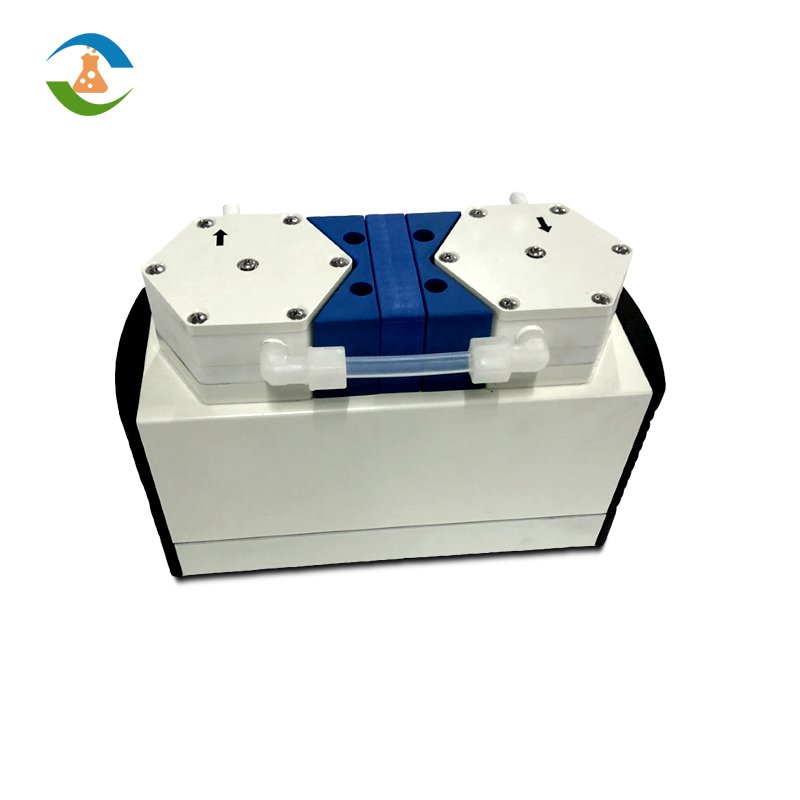

Diaphragm Vacuum Pump

It is a kind of variable volume vacuum pump. The working principle is that an eccentric wheel is sleeved on the motor shaft, one end of the connecting rod is sleeved on the eccentric wheel, and the other end is connected with a soft diaphragm. As the motor rotates, the connecting rod is driven to reciprocate, and the connecting rod drives the diaphragm fixed on the pump body to reciprocate, causing it to elastically deform, so that the volume of the pumping chamber on the pump body changes periodically. The pump body is equipped with intake and exhaust valves, which can inhale when the volume becomes larger, and exhaust when the container becomes smaller, so as to achieve the purpose of pumping. General water pumps and oil pumps do not have corrosion resistance. Diaphragm vacuum pumps are generally made of PTFE material with good corrosion resistance and excellent corrosion resistance.

You can choose the vacuum pump suitable for your equipment according to your needs, or you can contact us, we will provide solutions according to your usage scenarios and equipment.