Advantages of molecular distillation:

The molecular distillation system is made of high borosilicate glass, stainless steel and polytetrafluoroethylene. It has excellent corrosion resistance. It can watch the entire process of material feeding, evaporation, separation and discharging. It can be widely used in pharmaceuticals and food. , Petroleum, chemical, environmental protection and other industries.

Features of molecular distillation:

1. Very high evaporation efficiency, reducing residence time with minimal time delay.

2. The molecular distillation system is composed of high borosilicate glass, stainless steel and polytetrafluoroethylene, which has excellent corrosion resistance.

3. The main body of the molecular distillation system adopts high borosilicate glass, which can observe the operation of the whole process well.

4. The high-precision distiller makes the liquid form a complete film on the heating surface. The inner wall of the cylinder is smooth and clean, the inner wall is smooth and bright, and it is not easy to stick to dirt.

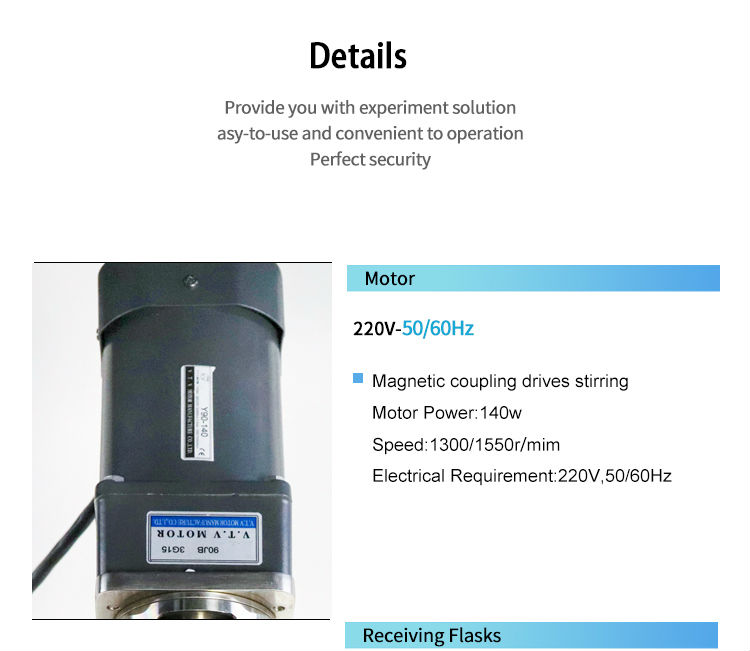

5. Frequency conversion speed motor, safe and reliable operation, with self-cooling fan, can work continuously for a long time.

6. The entire molecular distillation system has good sealing performance, and the minimum vacuum pressure can reach 0.1Pa.

7. The maximum temperature of the system can reach 230℃/300℃.

8. The maximum theoretical vacuum can reach 5Pa or 0.1Pa.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

Rotary vane water vacuum pump

Circulating water vacuum pump

Low temperature coolant circulation pump

Circulating water/oil bath

FAQ:

1. What are the advantages of molecular distillation over conventional distillation technology?

For the separation of high boiling point, heat sensitive and easily oxidizable materials, molecular distillation provides a good separation method. Because molecular distillation operates at a temperature much lower than the boiling point of the material, and the residence time of the material is short;

Molecular distillation can effectively remove substances in liquids such as organic solvents, odors, etc., which is an effective method for the desolvation of liquids after solvent extraction;

Molecular distillation can selectively distill out the target product and remove other impurities. Through multi-stage separation, more than two substances can be separated at the same time;

The fractionation process of molecular distillation is a physical process, so it can well protect the separated substances from pollution and infringement.

2. What is the working principle of molecular distillation?

Molecular distillation is a special liquid-liquid separation technology. It is different from the traditional distillation which relies on boiling point difference to separate, but relies on the difference in the mean free path of the molecular motion of different substances to achieve separation.

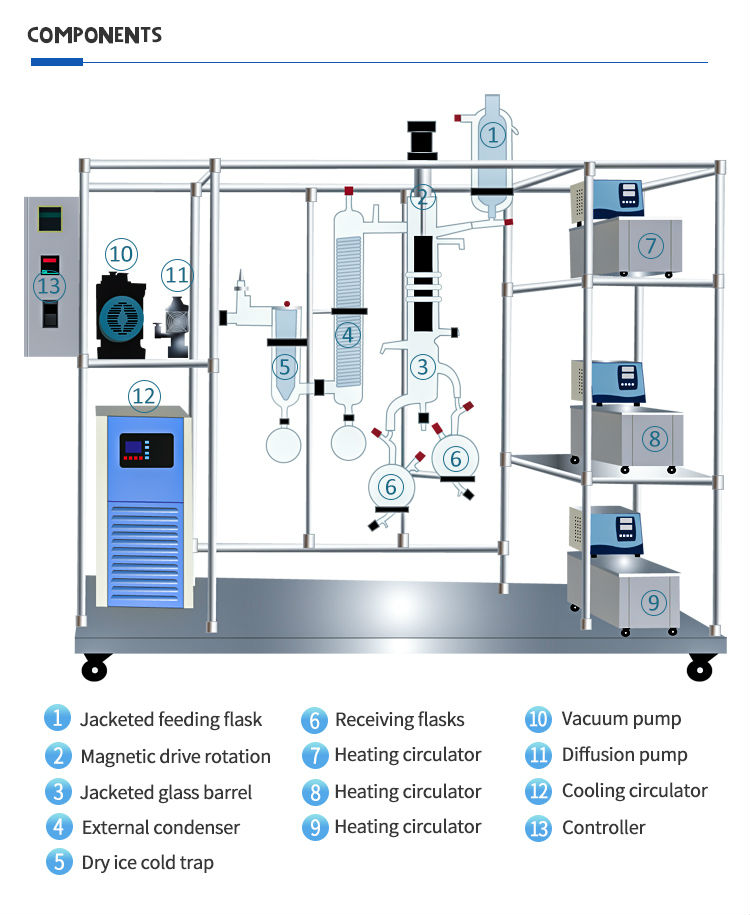

3. What are the components of molecular distillation?

Molecular evaporator, degassing system, feeding system, heating system, cooling vacuum system and control system.

Model | KMD-060 | KMD-080 | KMD-100 | KMD-150 | KMD-200 |

Effective evaporation area (m2) | 0.06 | 0.1 | 0.15 | 0.24 | 0.35 |

Barrel diameter(mm) | 60 | 80 | 100 | 150 | 200 |

Feeding funnel volume | 1L | 1.5L | 2L | 2L | 5L |

Feed rate (g/h) | 250-500 | 500-750 | 750-1500 | 1500-3000 | 3000-5000 |

Motor power (W) | 90 | 120 | 120 | 120 | 200 |

Maximum speed (rpm) | 0-500 | ||||

Distillate receiving flask | 1L | 1L | 2L | 3L | 5L |

Recicle receiving flask | 1L | 1L | 2L | 3L | 5L |

Operation temperature | Up to 200℃ | ||||