Advantages of molecular distillation:

Molecular distillation is a special liquid-liquid separation technology, which is different from traditional distillation which relies on boiling point difference. This is a process of distilling and purifying heat-sensitive substances or high-boiling substances by using the difference in the free path of motion of different substances under high vacuum. Mainly used in the fields of chemistry, medicine, petrochemical, perfume, plastic and oil.

Features of molecular distillation:

1. Adopt pressure-resistant precision gear pump for feeding and discharging, which can realize constant feeding and discharging speed;

2. Wide applicability, after the material enters the feeding tank, it can be kept warm throughout the whole process;

3. Materials with low viscosity and low boiling point to high viscosity and high boiling point can be separated;

4. Simple operation; only need to pour the material into the feed tank and set the button to carry out the whole operation;

5. The maximum temperature of the system can reach 300℃, which can realize precise temperature control

6. Safe and reliable operation; with self-cooling fan, can work continuously for a long time

7. The evaporation efficiency is very high, which can reduce the retention time and has the smallest time delay

8. The main body of the molecular distillation system is made of high borosilicate glass, and the operation process of the whole process can be well observed

9. Non-toxic, harmless, non-polluting, non-residual, and can obtain pure and safe products.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

Grouped equipment:

Rotary vane vacuum pump

Circulating water vacuum pump

Low temperature coolant circulation pump

Circulating water/oil bath

FAQ:

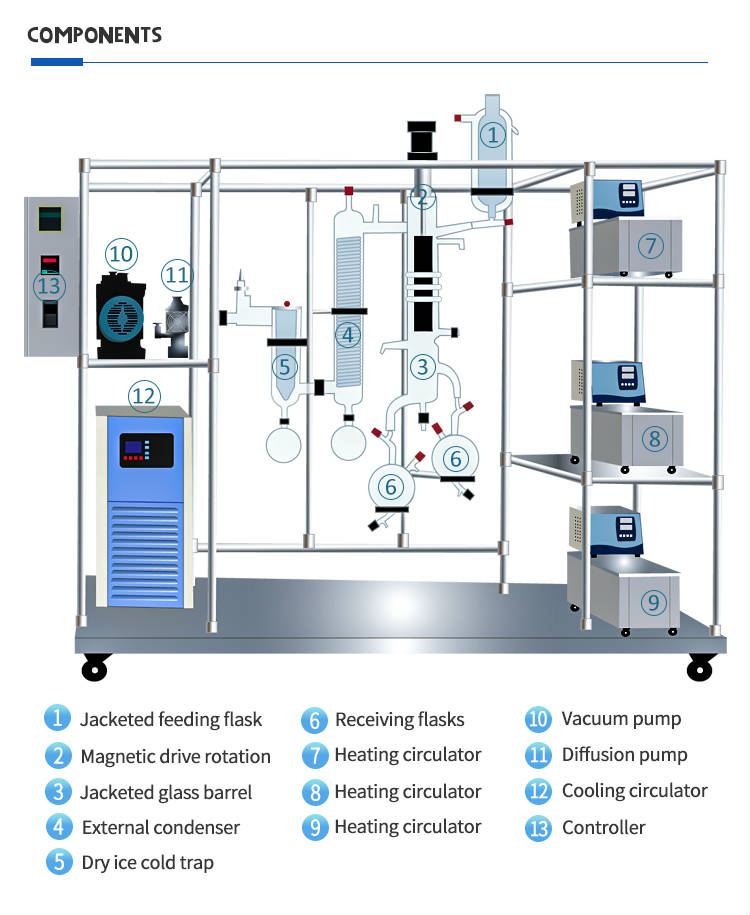

What are the equipment components of molecular distillation?

A complete set of molecular distillation equipment consists of three types of equipment: a short-path distiller, a circulating water vacuum pump and a low-temperature coolant circulating pump.

What are the similarities between molecular distillation equipment and thin film evaporator?

1. All are liquid-liquid separation, solid-liquid separation is not possible; the material requirements are that it can flow at high temperatures, and cannot be solid after heating, but can become solid after cooling

2. Vacuum distillation done all

3. Evaporative separation by forming a thin film on the evaporation surface

What materials are used for the components of the molecular distillation system?

The molecular distillation system is composed of high borosilicate glass, 316L stainless steel and polytetrafluoroethylene, and has excellent corrosion resistance. The maximum theoretical vacuum can reach 5Pa or 0.1Pa.

Model | KMD-060 | KMD-080 | KMD-100 | KMD-150 | KMD-200 |

Effective evaporation area (m2) | 0.06 | 0.1 | 0.15 | 0.24 | 0.35 |

Barrel diameter(mm) | 60 | 80 | 100 | 150 | 200 |

Feeding funnel volume | 1L | 1.5L | 2L | 2L | 5L |

Feed rate (g/h) | 250-500 | 500-750 | 750-1500 | 1500-3000 | 3000-5000 |

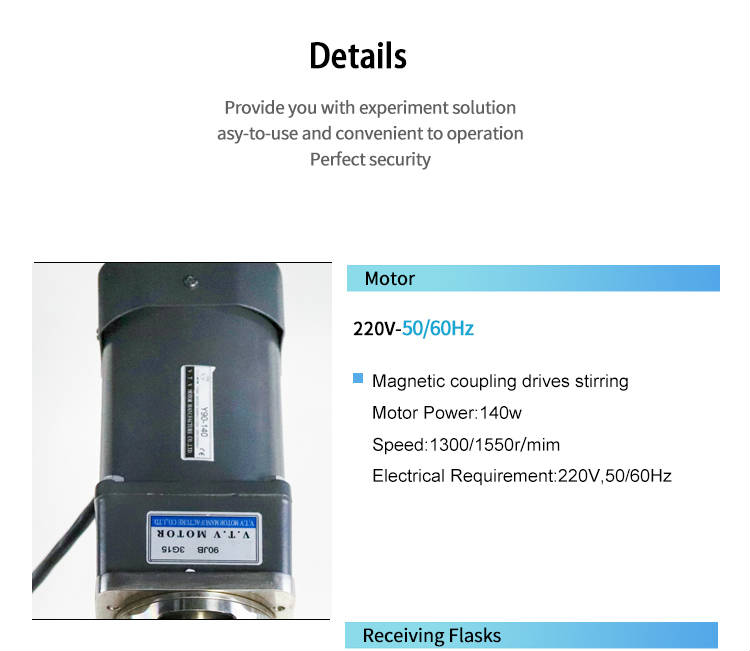

Motor power (W) | 90 | 120 | 120 | 120 | 200 |

Maximum speed (rpm) | 0-500 | ||||

Distillate receiving flask | 1L | 1L | 2L | 3L | 5L |

Recicle receiving flask | 1L | 1L | 2L | 3L | 5L |