Advantages of high constant temperature circulating water and oil bath:

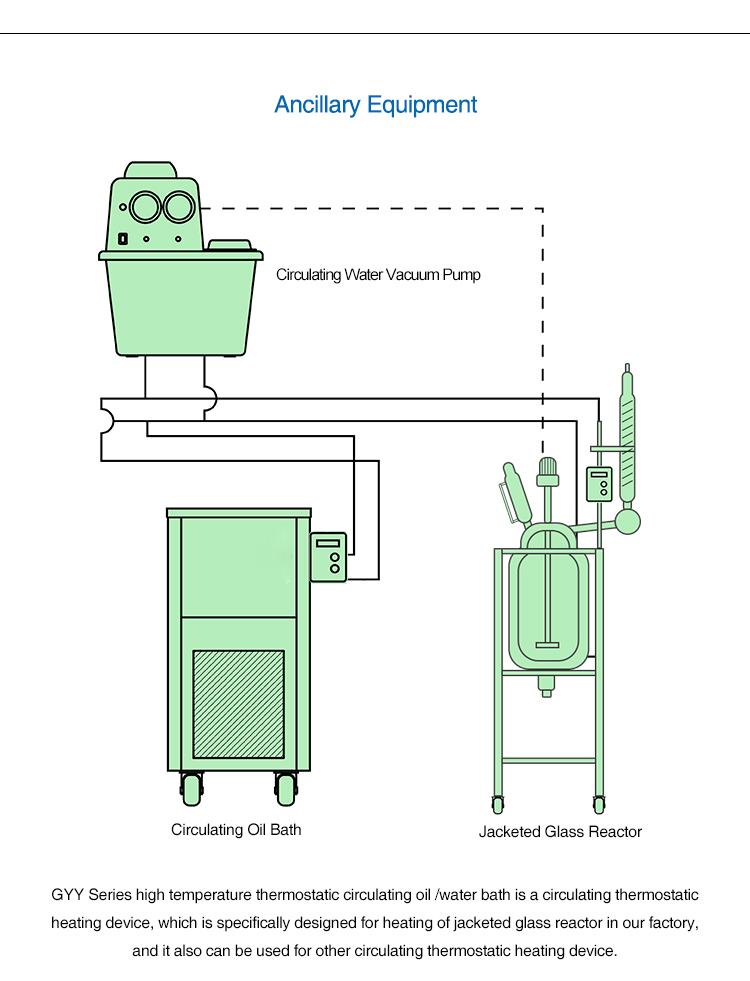

GYY series high temperature constant temperature circulating water and oil bath is a circulating and constant temperature heating device specially designed and produced for the company's double-layer glass reactor. It has compact and reasonable structure, safe and convenient use, accurate temperature control, and controllable output flow. Features such as energy saving. It can conveniently provide a circulating constant temperature heat source for the double-layer glass reactor, and can also be used in other devices and occasions that require circulating constant temperature heating.

Features of high constant temperature circulating water and oil bath:

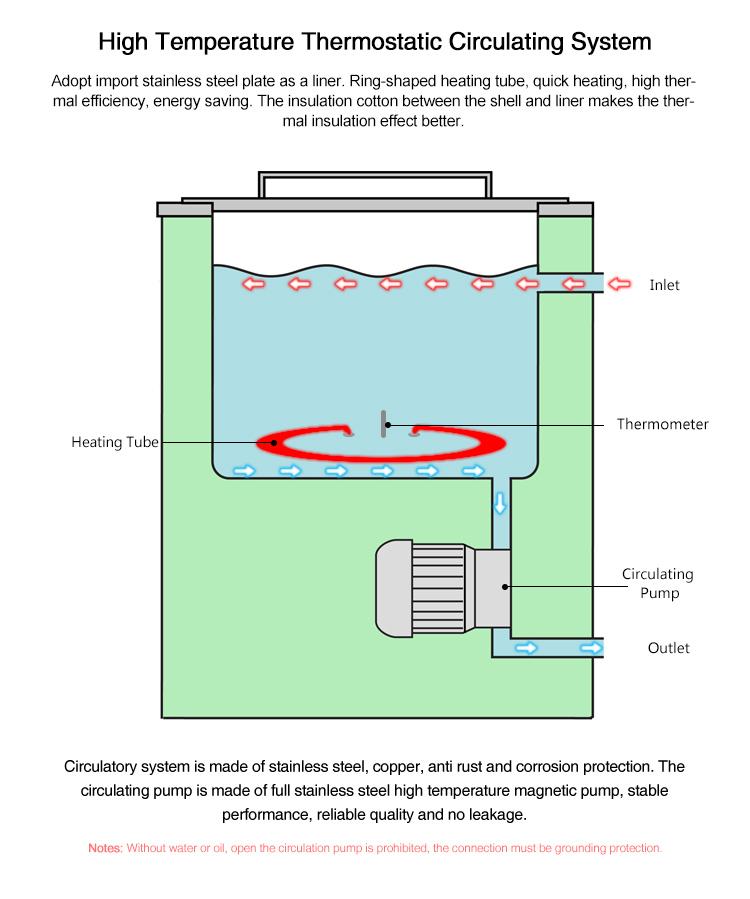

1. The oil bath shell and inner liner are protected by temperature insulation cotton, which has excellent heat preservation effect.

2. Digital display temperature control, simple operation and eye-catching.

3. The electric heating tube will be in the middle of the oil, heating fast, high thermal efficiency, low power consumption, and electronic constant temperature.

4. The air-cooled circulating water bath/oil bath can be forced air-cooled to achieve rapid cooling.

5. The circulating pump is used in all stainless steel high temperature canned motor pumps, which has the advantages of stable performance, reliable quality and no leakage.

6. The container is made of high-quality stainless steel and is corrosion-resistant.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

1. What are the precautions for operating high temperature constant temperature circulating water and oil bath?

To ensure safety, please connect the ground wire when using.

Dry burning without refueling is strictly prohibited.

When not working, the power supply should be cut off to avoid accidents. It can be customized according to customer requirements.

2. Features of high temperature constant temperature circulating water and oil bath:

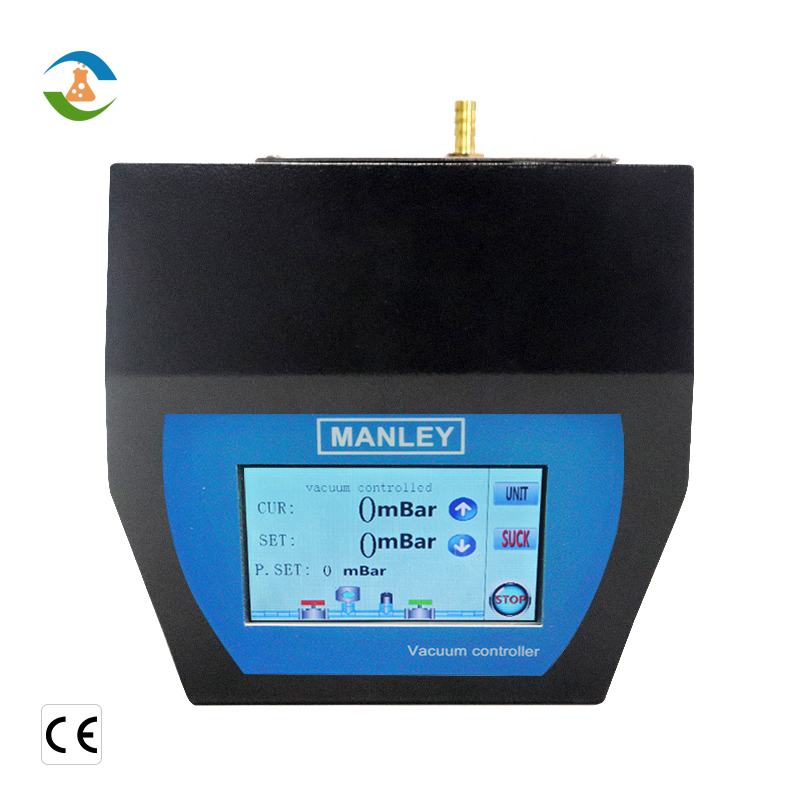

1. The temperature control system of GYY high temperature circulating oil bath pot/tank has been improved by us. Whether it is digital display or display display, SCR (below 3KW) or solid state relay (above 3KW) is added as the heating control core of the machine. , The principle of thyristor is to adjust the voltage and temperature by the weak electric signal of the instrument. The solid-state relay relies on the micro-voltage signal of the instrument to be turned on and off as a switch output, so as to realize the control of the output terminal of the heater.

2. GYY high temperature cycle The temperature sensing part of the oil bath/tank instrument adopts K-type armored platinum resistance, and the envelope adopts copper tube coating process, which has fast heat conduction. The platinum resistance sensor is a temperature measurement product with the characteristics of small resistance and high accuracy.

3. What is the temperature range of the high temperature constant temperature circulating water and oil bath?

GYY series high temperature constant temperature circulating water and oil bath: capacity: 5L-200L, temperature range: 0-200℃.

4. What are the characteristics and uses of high temperature constant temperature circulating water and oil bath?

The high temperature circulating oil bath adopts an all-stainless steel shell, and the designed and produced circulating and constant temperature heating device has the characteristics of compact and reasonable structure, safe and convenient use, accurate temperature control, controllable output flow, and energy saving. It can conveniently provide a circulating constant temperature heat source for laboratory equipment such as single and double-layer reactors/jacket reactors/rotary evaporators/glass reactors/vacuum reactors, and can also be used in other devices and occasions that require circulating constant temperature heating.

Model | 5L | 10L | 20L | 30L | 50L | 80L | 100L | |

Function | Liquid storage volume (L) | 5 | 10 | 20 | 30 | 50 | 80 | 100 |

No-load maximum temperature(℃) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

Heating power (kW) | 2.8 | 1.5 | 2 | 2.8 | 2.8 | 3 | ||

Cycling performance | Power | 220V/50HZ 380V/50HZ(50L/80L) | ||||||

Pressure | 1.45Mpa | |||||||

Cycle way | Sealed magnetic pump cycles | |||||||

Flow rate(L/min) | 15-20 | 20-25 | ||||||

Tempe control performance | Temp control range (℃) | Water bath:RT~99; Oil bath:RT~250 | ||||||

Temperature error | ≤2.50% | |||||||

Working condition | Power | 380/220V 50Hz | ||||||

Humidity | 60% | |||||||

HTF viscosity | Below 500C℃·S·t | |||||||

Currents(A) | 10 | |||||||

Optional Configuration | Explosion-proof motors and electrical | |||||||

The number of heating tube | 1 | 2 | 3 | |||||

Liner Size (cm) | 25*22 | 25*25 | 30*30 | 35*30 | 45*35 | 50*45 | 55*50 | |

Overall dimensions (cm) | 60*40*68 | 60*45*70 | 63*48*70 | 70*54*85 | 75*58*85 | 86*68*90 | 90*70*95 | |

Weight (kg) | 35 | 45 | 60 | 60 | 75 | 90 | 105 | |