Advantages of high constant temperature circulating water and oil bath:

The high temperature constant temperature circulating water and oil bath are widely used for drying, concentrating, distilling, impregnating chemical reagents, impregnating drugs and biological products, and can also be used for constant temperature heating in water baths and other temperature tests. They are biological, genetic, viral, aquatic, environmentally friendly, An indispensable tool for education and scientific research in medicine, health, biochemical laboratories, and analysis rooms.

Features of high constant temperature circulating water and oil bath:

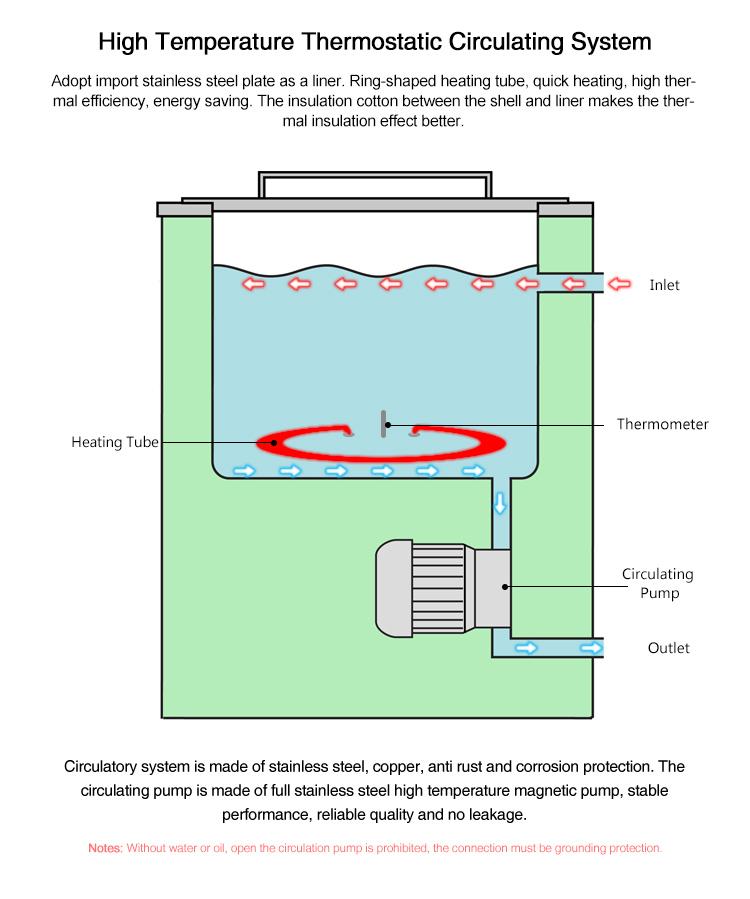

1. The container is made of high-quality stainless steel and is corrosion-resistant.

2. Use 304 stainless steel as the inner tank. The shell is made of high-quality plates and electrostatic spraying.

3. The digital display adopts PI.D control, which has the advantages of precise temperature control and small temperature shock.

4. The circulation system is made of stainless steel and copper, which has the characteristics of anti-rust and anti-corrosion.

5. Vertical structure, equipped with casters, easy to move.

6. Adopt solid state relay control circuit, no contact. No open flame, increase life span.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

1. What are the uses of high temperature constant temperature circulating water and oil bath?

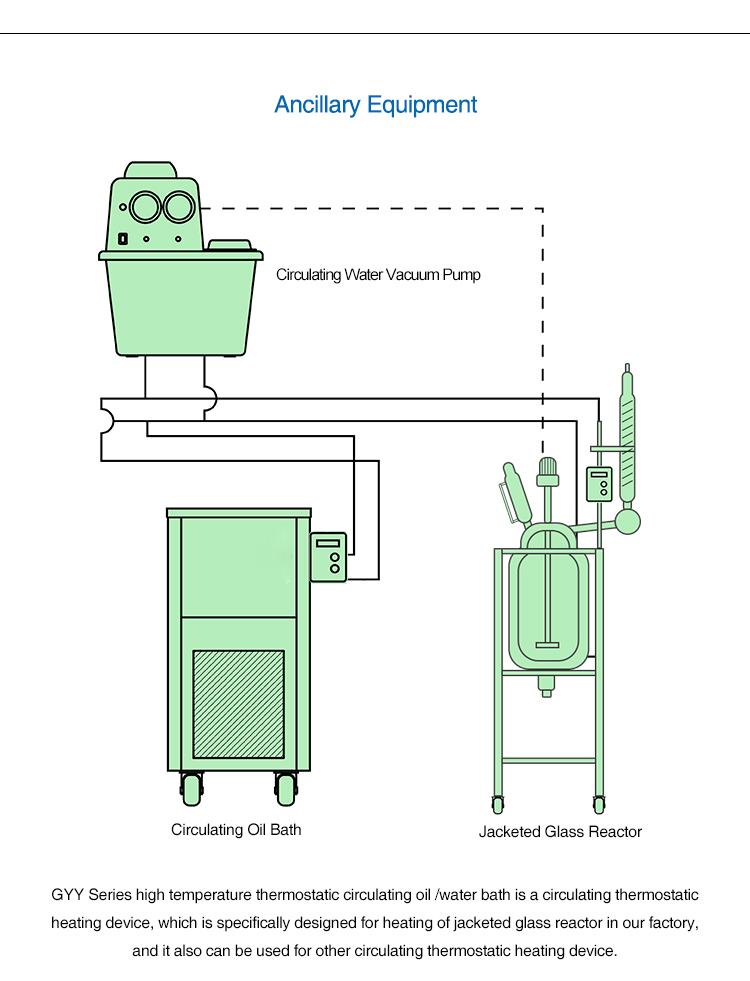

GYY series high temperature constant temperature circulating water and oil bath is a circulating and constant temperature heating device specially designed and produced for the company's double-layer glass reactor. It has compact and reasonable structure, safe and convenient use, accurate temperature control, and controllable output flow. Features such as energy saving. It can conveniently provide a circulating constant temperature heat source for the double-layer glass reactor, and can also be used in other devices that require circulating constant temperature heating. To

2. Maintenance of high temperature constant temperature circulating water and oil bath

In order to improve your quality of use, please use (320 high temperature heat transfer oil).

Maintain the oil level during use and change the oil regularly. When changing the oil, drain all the old oil, flush the inside with new oil, and then add new oil to prevent impurities from entering during use, so as not to affect the quality of the oil.

3. What is the circulation mode of the high temperature constant temperature circulating water and oil bath?

Circulation method: magnetic pump circulation

4. Instructions for use of high temperature constant temperature circulating water and oil bath:

When using a constant temperature oil bath, you must first add oil to the pot, and then turn on the power. The digital temperature controller displays the actual measured temperature, adjust the knob switch, and observe the reading to the required set temperature value. When the set temperature value exceeds the oil When it is warm, the heating indicator light is on, indicating that the preheater has started to work. When the oil temperature reaches your desired temperature, the constant temperature indicator light is on and the heating indicator light is off. It should be noted that the pot oil cannot use the electric heating tube to expose the oil surface to avoid burning Electric heating tube, causing leakage phenomenon

Model | 5L | 10L | 20L | 30L | 50L | 80L | 100L | |

Function | Liquid storage volume (L) | 5 | 10 | 20 | 30 | 50 | 80 | 100 |

No-load maximum temperature(℃) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

Heating power (kW) | 2.8 | 1.5 | 2 | 2.8 | 2.8 | 3 | ||

Cycling performance | Power | 220V/50HZ 380V/50HZ(50L/80L) | ||||||

Pressure | 1.45Mpa | |||||||

Cycle way | Sealed magnetic pump cycles | |||||||

Flow rate(L/min) | 15-20 | 20-25 | ||||||

Tempe control performance | Temp control range (℃) | Water bath:RT~99; Oil bath:RT~250 | ||||||

Temperature error | ≤2.50% | |||||||

Working condition | Power | 380/220V 50Hz | ||||||

Humidity | 60% | |||||||

HTF viscosity | Below 500C℃·S·t | |||||||

Currents(A) | 10 | |||||||

Optional Configuration | Explosion-proof motors and electrical | |||||||

The number of heating tube | 1 | 2 | 3 | |||||

Liner Size (cm) | 25*22 | 25*25 | 30*30 | 35*30 | 45*35 | 50*45 | 55*50 | |

Overall dimensions (cm) | 60*40*68 | 60*45*70 | 63*48*70 | 70*54*85 | 75*58*85 | 86*68*90 | 90*70*95 | |

Weight (kg) | 35 | 45 | 60 | 60 | 75 | 90 | 105 | |