Advantages of supercritical co2 extraction:

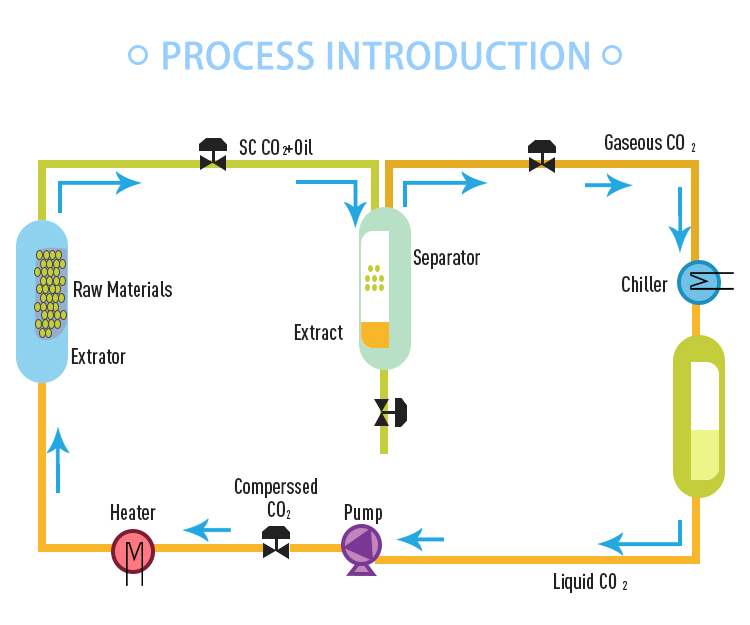

The essential feature of the supercritical carbon dioxide extraction machine is to use environmentally friendly, non-toxic, non-residual CO2 instead of water or organic solvents as the extraction medium, and extract under conditions close to room temperature. Its biggest advantage is to separate the extraction (refining) ) And removal of solvents, etc.

Features of supercritical co2 extraction:

1. Carbon dioxide is cheap, non-flammable, non-explosive, sterilizing, and non-bacterial.

2. Low critical temperature, suitable for the extraction and purification of heat-sensitive compounds.

3. The extraction temperature is low, usually no more than 80°C (mostly around 50°C), which will not destroy the natural activity of the active ingredients.

4. The extraction speed is fast, non-toxic, non-flammable, safe to use, and does not pollute the environment.

5. It can provide an inert environment to avoid product oxidation and does not affect the effective components of the extract.

6. Reasonable structure: SFE equipment is a high-pressure equipment. Therefore, we use short connections, high strength, and light vibration in the design to ensure safety and efficiency, so as to reduce production costs and increase extraction speed.

7. Automatic operation: Extraction kettle cover and quick-opening structure, use the remaining gas of the system to open the cover, double extraction kettles work alternately, changing the kettle time is less than 5 minutes, saving a lot of time than the traditional method, but also reducing labor intensity.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

The main technical parameters of supercritical CO2 extraction

1. Extraction kettle: 05L, 1, 2L, 5L/50 Mpa, 10L, 24L/4 OMpa, 50-200 L/32 Mpa, dual-purpose solid and liquid. The water distribution jacket can be recycled and the temperature is adjustable.

2. Separating kettle: 03-10L/30Mpa, 50-200L/16-22Mpa. The water distribution jacket can be recycled and the temperature is adjustable.

3. The inner diameter of the distillation column is 125×2-3m/30 mpa, 135×2-3m/3 ompa, Φ48x4-6m/30 mpa, 178x4-6m30 mpa, which can also be divided into 4 sections, 6 sections, and 8 sections according to the process requirements. Temperature control; the user can choose the corresponding filler according to the process requirements.

4. CO2 high pressure pump: 20L/40 Mpa·h three plunger frequency modulation, 50L/50 Mpa·h three plunger frequency modulation, 400 L/40 Mpa·h three plunger frequency modulation, 800 L/40 Mpa·h three plunger frequency modulation Frequency modulation, pump head cooling system.

5. In the extraction process, the carrier pump is used for extraction to change the polarity of CO2 and expand the scope of application.

6. Refrigeration system: equipped with semi-hermetic compressor and hermetic compressor, the refrigeration capacity meets the technological requirements.

7. Heat exchange and temperature control system: According to the process requirements, the extraction kettle, separation kettle and rectification tower are equipped with heat exchange system and temperature control system respectively. Double screens control the temperature of the water bath, test the temperature of the CO2 fluid, and the temperature control accuracy is ±1℃.

8. Pressure control (protection): The outlet of the high-pressure pump is assigned a contact pressure gauge, the working pressure is set, and the overpressure protection automatically stops the pump. The high-pressure pump, extraction kettle, separation kettle, and distillation tower are all equipped with a maximum working pressure safety valve, and automatic pressure relief protection for overpressure. The outlet of the pumping kettle is equipped with a back pressure valve system. Ensure that the pressure is stable, easy to adjust, and the pressure control accuracy is ±0.1Mpa.

9. Flow display: metal rotor flowmeter, digital display remote transmission, respectively display instantaneous flow and cumulative flow

10. Piping: containers, valves, fittings and pipes in contact with fluid are made of stainless steel

11. Others: three-phase four-wire system 380 V/50 Hz, CO2 food grade ≥99.5%, user power supply.

What is the effect of the extraction temperature on the supercritical co2 extraction?

The influence of temperature on the dissolving ability of supercritical fluids is more complicated. Under certain pressure, increasing the temperature will increase the volatility of the extract, which increases the concentration of the extract in the supercritical gas phase, thereby increasing the amount of extraction; but On the other hand, as the temperature increases, the density of the supercritical fluid decreases, so that the solubility decreases, and the extraction volume decreases.

What are the applications of supercritical co2 extraction?

The characteristics of supercritical CO2 extraction determine its wide range of applications. For example, in the pharmaceutical industry, it can be used for the extraction of effective ingredients of Chinese herbal medicines, the refining of heat-sensitive biological products, and the separation of lipid mixtures; in the food industry, the extraction of hops, the extraction of pigments, etc.; in the perfume industry, natural and Refining of synthetic spices; separation of mixtures in the chemical industry, etc.