We are a manufacturer of rotary evaporators in China. Our rotary evaporators need models such as the 2L rotary evaporator, 10L rotary evaporator, 20L rotary evaporator, etc. Contact us to get the best price.

What is a rotary evaporator?

Rotary evaporators are mainly used for concentration, solvent separation, and crystallization in medicine, chemistry, and biopharmaceutical industries. Rotary evaporators can also be used for the distillation and extraction of essential oils and other vegetable oils. They are more commonly used to extract CBD components in plant hemp. It can perform continuous constant temperature heating in a closed environment under vacuum conditions, the rotating bottle keeps rotating at a constant speed, and the material forms a large area of film on the inner wall of the rotating bottle to achieve the effect of distillation.

What are the advantages of using a rotary evaporator for distillation and extraction?

1. The heating area of the rotary evaporator is large and the evaporation speed is fast.

2. It can effectively inhibit the boiling of the material so as not to damage the material.

3. Convenient operation and good concentration effect.

4. It can collect materials with different boiling points.

5. Under the action of the high-efficiency condenser, the hot steam can be quickly vaporized to speed up the efficiency of the evaporator.

6. A relatively high degree of vacuum can be reached.

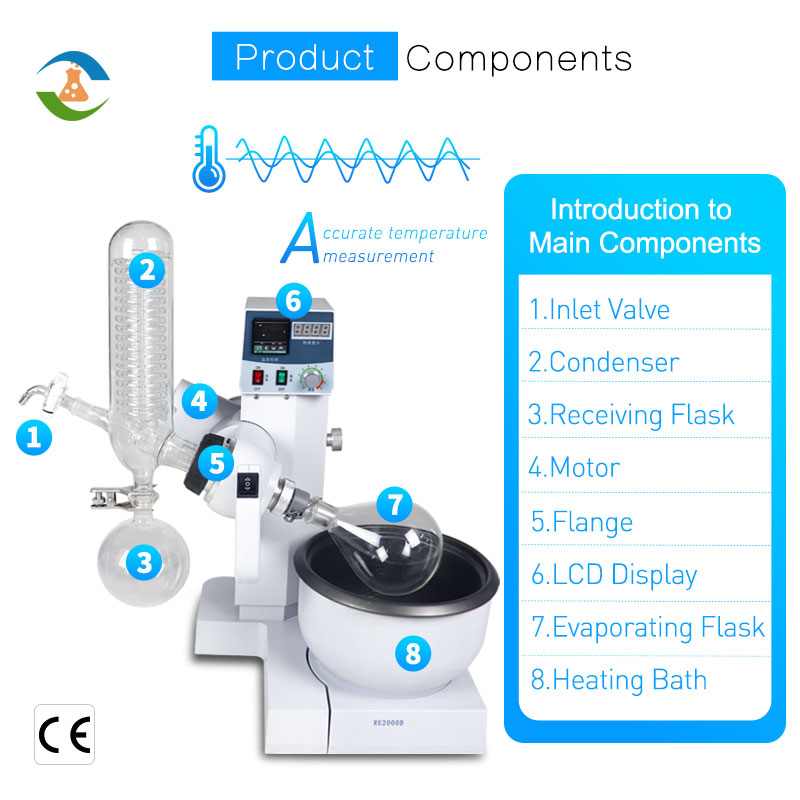

What are the parts of the rotary evaporator?

·Rotating motor: driving the evaporating flask through rotation.

·Evaporation pipeline: the rotating support shaft of the evaporating flask, and the vacuum-sealed pipeline that draws out steam from the material.

·Vacuum system: reduce the pressure in the evaporator system and lower the boiling point of the material.

·Heating bath: water or oil is often used to heat materials.

·Condenser: In order to speed up the condensation efficiency, it is usually made into a double-snake surrounding type, and then a condensing agent such as dry ice and acetone is added to condense the sample.

·The condensed water collection bottle at the bottom of the condenser: used to capture the distilled solvent after re-condensation and collect the sample.

·Lifting device: a mechanical or motorized mechanism that can quickly lift the evaporating flask from the heating bath.