Many people like roses, because roses are a symbol of good love and auspiciousness. Rose essential oil has antibacterial, antispasmodic, bactericidal, aphrodisiac, purifying, sedative, and tonic properties. So, how to distill rose essential oil?

FBL machinery equipment co., LTD will answer you in detail. All experimental instruments used below were provided by FBL: rotary evaporator, dlsb 30 80, essential oil distillation machine.

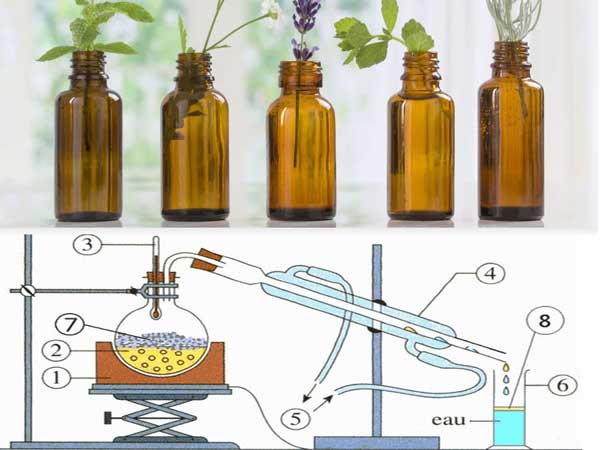

1 Experimental Principle

The volatile oil components contained in roses: citronellol, geraniol and linalool, citronellol, phenethyl alcohol, nerol, syringol, farnesol and its esters, sesquiterpenes and their derivatives, etc. Therefore, the chemical properties of rose essential oil are stable, insoluble in water, easily soluble in organic solvents, and can evaporate together with water vapor. In this experiment, the crude rose essential oil was obtained by water distillation and separation by short path distillation kit thc.

2 Experimental Equipment

Instrument reagent separatory funnel, 100mL graduated cylinder, rotary evaporator, rubber stopper, distillation head, 200°C thermometer, straight condenser tube, liquid connection tube, 250mL conical flask, and rubber tube connecting the water inlet and outlet, Electronic scales; fresh roses, 0.1 g/mL sodium chloride, anhydrous sodium sulfate and other equipment

3 Rose Essential Oil Extraction Process

Installation Of Short Path Distillation Unit

• Install the injector (tighten the injector clockwise), the first, second and third stage receiving bottles, and turn on the cooling water circulation button;

• Turn on the wiper rotor and adjust to the specified speed (no more than 400 r/min);

• Turn on the vacuum pump after the liquid nitrogen reaches the required level (not less than 1/2 of the condenser column volume);

• When the pressure no longer drops, adjust the vacuum pump trim valve (not less than 0.5 mbar);

• After the pressure is adjusted in place, rotate the injector valve counterclockwise to adjust the injection speed;

• During the operation of the equipment, the feed liquid can be added at any time through the injector;

• When the liquid volume in the sampler remains about 50 m| and no more samples are injected, turn off the vacuum pump, and adjust the trim valve. Injector, pour out the remaining sample solution and replace it with absolute ethanol;

• Replace the first and second receiving bottles, install empty bottles, unscrew the injector, slowly inject absolute ethanol, and use the residual heat to clean the equipment;

• After cleaning, turn off the cooling water and rotor, remove the injector and the receiving bottle, and wash them again;

• Turn off the power and clean the countertop. Equipment cleaning and maintenance: Due to the precision and importance of the equipment, the person in charge of the instrument or a full-time person must be responsible for the cleaning and maintenance of the equipment.

Experimental Procedure

• Rinse the petals with water to remove dust and other impurities on them, and drain the water;

Weigh 50 g rose petals, put it into a 500 mL round-bottomed flask, and add 200 mL of distilled water;

• Install the short path distillation unit according to the previous step: you can add a few grains of zeolite to the distillation bottle to prevent the liquid from over-boiling; open the faucet and slowly pour cold water;

• Then start heating: when heating, it can be observed that the liquid in the distillation flask gradually boils and the vapor gradually rises;

• The thermometer reading also rose slightly: when the top of the vapor reaches the mercury ball of the thermometer, the thermometer reading rises sharply; during the whole distillation process, it should be ensured that there are often droplets formed by condensation on the mercury ball of the thermometer;

• Control the time and speed of distilling, usually 1~2 drops per second; after distillation, collect the milky white emulsion in the flask, and add sodium chloride with a mass concentration of 0.1 g/mL to the conical flask solution to make the emulsion layered: then pour it into a separatory funnel, and use the separatory funnel to completely separate the oil layer and the water layer;

• Open the top plug, then slowly unscrew the piston, release the rose essential oil in the lower layer, collect it in a receiving bottle, add anhydrous sodium sulfate to the receiving bottle, absorb the water contained in the oil layer, and leave it overnight;

• In order to better separate the two layers of oil and water, attention should be paid to the correct use of a separatory funnel during operation. The heat source should be withdrawn first, then the water should be stopped, and finally the distillation unit should be disassembled. The disassembly sequence is reversed from that of installation.

4 Precautions For The Use Of Short Path Distillation Unit

• The equipment is heated by the outer interlayer circulating hot oil, the temperature is high, do not touch;

• The short-path distillation equipment is connected with the vacuum pump, so special attention should be paid to check the tightness of the connection of each component when starting up;

• The main components of the vacuum pump trim valve are high-density stainless steel needles. Before opening, the condensation column must be filled with liquid nitrogen. If the injection volume is large in one day, it is recommended that the primary receiving port be connected to a rotary valve, and the bottom end should be supported by a lifting frame. The equipment cannot be stopped for sampling and bottle replacement during operation. If it is stopped, it will be restarted the next day.

• The sampler, the first, second and third receiving bottles are all ground glass, and they are all fixed by pinch, so do not use excessive force during operation.

These are the questions that FBL Laboratory Equipment Co., Ltd. answers for you. In addition, rose essential oil has long been one of the most popular flower-shaped essential oils in the international food industry market, mainly used in soft drinks, candy, ice cream, seasonings, health food, etc. In the chemical industry, it can be used to produce high-grade fragrances and high-grade cosmetics. The market price is expensive and the demand is huge. In addition to short-path distillation that can extract rose essential oil, there are many other equipments that can extract rose oil, such as: rotovap machine, cdu 1000 distillation, etc. To learn more or to order a product, please contact us.