Advantages of muffle furnace:

The muffle furnace is made of vacuum-formed high-purity alumina multi-light material, which has low heat storage, excellent heat preservation and energy saving effects, and greatly reduces the total weight of the electric furnace. The double-layer air-cooled structure ensures that the surface temperature of the furnace shell is close to room temperature. The temperature control system adopts industrial grade 0.2 intelligent instrument, PID control, 51-segment heating curve, and high degree of automation. The laboratories of the institute and industrial and mining enterprises are ideal equipment for the sintering, melting, analysis and development of metals, non-metals and other composite materials.

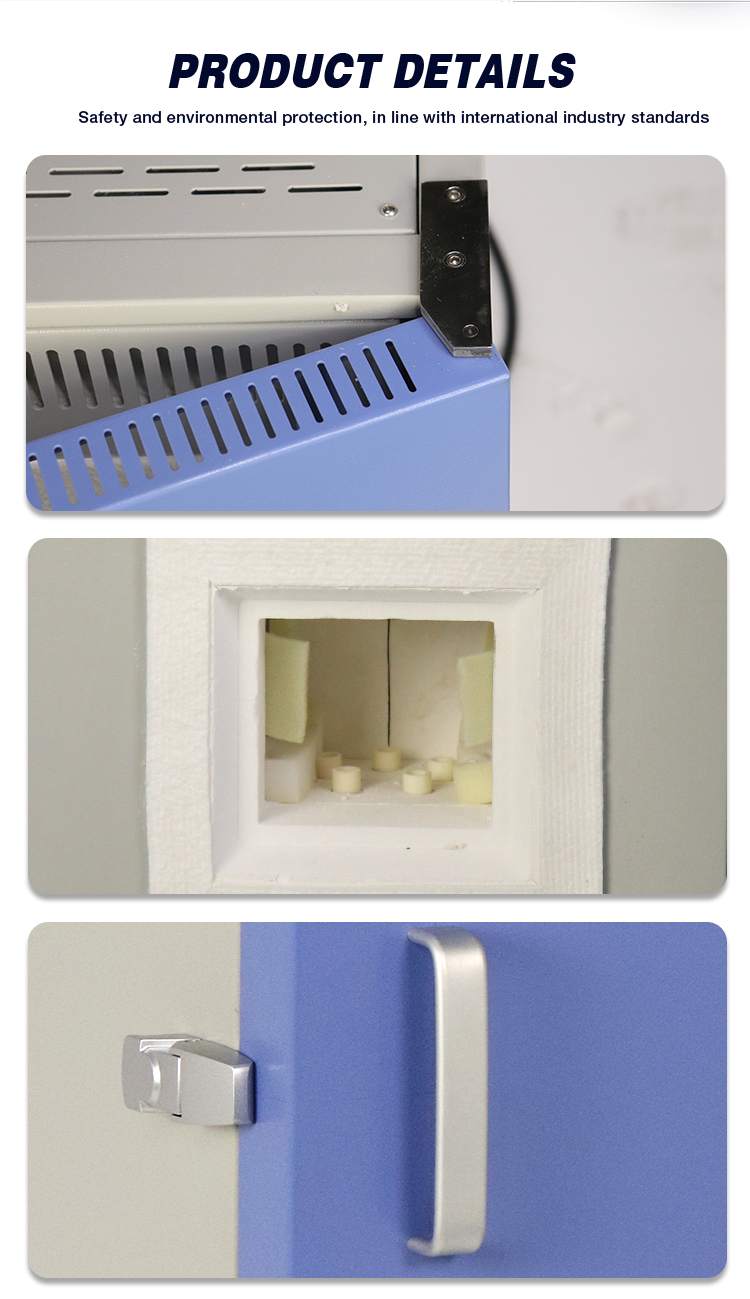

Features of muffle furnace:

1. The temperature rise is fast and easy to control, and the temperature can be programmed from room temperature to 1000-1200°C within a few minutes, with 5 steps of independent heating

2. Direct ashing without carbonization, omitting the carbonization process of evaporating moisture and burning to remove organic matter before putting the sample into the muffle furnace

3. Flexible choice of crucible, metal, quartz and ceramic crucibles can all be used

4. Microwave and auxiliary heat in one, ashing more evenly

5. Quartz inner cavity, clean and ashing

6. The temperature is not lower than 1200℃;

7. Equipped with the function of constant temperature time control. After the temperature of each step rises to the set value, the timer automatically starts to work and keeps the constant temperature according to the set time;

8. Possess the function of presetting the heating rate of each step;

9. The inner wall of the furnace is made of quartz material, so there is no need to consider that the heating wire is exposed to the furnace body;

10. With automatic power-off function when opening the door.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

1. Classification of muffle furnace

The muffle furnace has the following classifications according to its heating elements, temperature and controller: 1) According to the heating elements, there are: electric furnace wire muffle furnace, silicon carbide rod muffle furnace, silicon molybdenum rod muffle furnace;

According to the operating temperature, it is generally divided into: box muffle furnace below 1000 degrees, 1100 degrees to 1300 degrees muffle furnace (silicon carbide rod muffle furnace), and silicon molybdenum rod muffle furnace above 1600 degrees.

According to the controller, there are the following types: PID adjustment control muffle furnace (SCR digital display temperature controller), program control muffle furnace (computer temperature program controller);

According to the insulation materials, there are two types: ordinary refractory brick muffle furnace and ceramic fiber muffle furnace.

2. Precautions for installation of muffle furnace

After unpacking, check whether the muffle furnace is intact and the accessories are complete.

1. The general muffle furnace does not need special installation. It only needs to be placed flat on a solid cement table or shelf indoors, and there should be no flammable and explosive materials around. The controller should avoid vibration, and the location should not be too close to the electric furnace to prevent internal components from not working properly due to overheating.

2. Insert the thermocouple into the furnace with 20-50mm, and fill the gap between the hole and the thermocouple with asbestos rope. It is better to use compensation wire (or insulated steel core wire) to connect the thermocouple to the controller. Pay attention to the positive and negative poles, and do not connect them reversely.

3. An additional power switch needs to be installed at the entrance of the power cord to control the total power supply. In order to ensure safe operation, the electric furnace and the controller must be reliably grounded.

4. Before use, adjust the temperature controller to the zero point. When using the compensation wire and cold junction compensator, adjust the mechanical zero point to the reference temperature point of the cold junction compensator. Mingsheng Furnace Co., Ltd. arranges and provides it. No compensation is used. When the wire is connected, the mechanical zero point is adjusted to the zero scale position, but the temperature indicated is the temperature difference between the measuring point and the cold junction of the thermocouple.

5. Adjust the set temperature to the required operating temperature, and then turn on the power supply. Turn on work, the electric furnace is energized, and the input current, voltage, output power and real-time temperature are displayed on the control panel. As the internal temperature of the electric furnace increases, the real-time temperature will also increase. This phenomenon indicates that the system is working normally.

Mode | KD-BR-12N | KD-BR-14S | KD-BR-17M |

Furnace size(mm) | 100X100X100, 200X200X200,300X300X300, 300X300X400,400X400X400,customize | ||

Maximum temperature(℃) | 1200 | 1400 | 1700 |

Operating temperature(℃) | 1100 | 1300 | 1600 |

Heating rate (℃/ min) | 20 | 15 | 15 |

Temperature control accuracy | ±1 | ±1 | ±1 |

Heating element | Molybdenum resistance wire | Silicon carbide rod | Silicon molybdenum rod |

Rated voltage | 220,380 | ||