Advantages of magnetic stirrer:

The magnetic stirrer is driven by a micro-motor to drive a high temperature resistant strong magnet to rotate to generate a rotating magnetic field to drive the stirrer in the container to rotate, thereby stirring, mixing or auxiliary heating the liquid in the container, so that the solution can be fully mixed at the set temperature. Used in biology, medicine, chemistry and other fields.

Features of magnetic stirrer:

1. The magnetic stirrer adopts round ceramic, metal surface, anti-corrosion, smooth and easy to clean.

2. The base material of the heating table is aluminum alloy, and the exterior is sprayed with a composite material coating, which has good thermal conductivity and 3. It has corrosion resistance, and the smooth mixing table is easy to clean and no pollutants stay.

4. Stepless speed regulation, stable low speed, strong high speed.

5. 50~1000mI standard or non-standard reaction flask, non-magnetic metal and other non-metal containers can be heated.

6. DC brushless speed regulating motor, stable, low noise, long life, no sparks.

7. Patented new aluminum material, high temperature. Resistance, corrosion resistance and insulation properties.

8. The alarm indicator for excessive top plate temperature can prevent accidental injury.

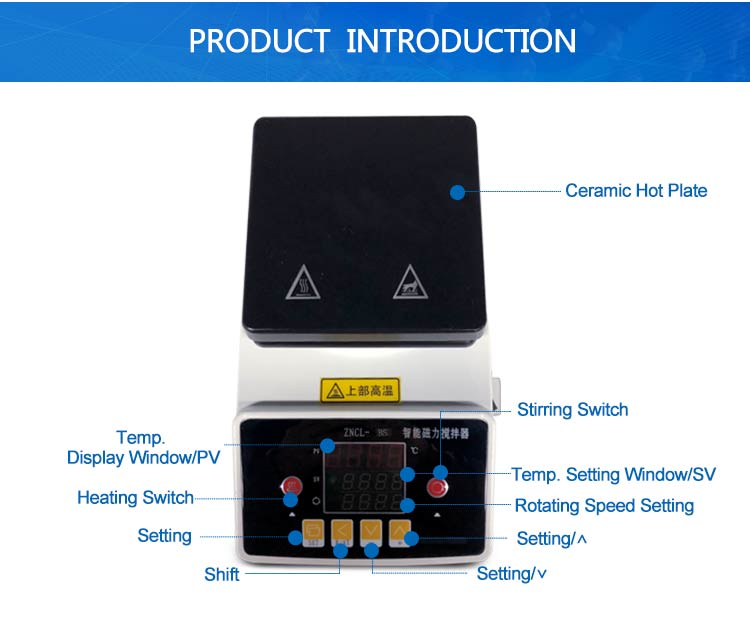

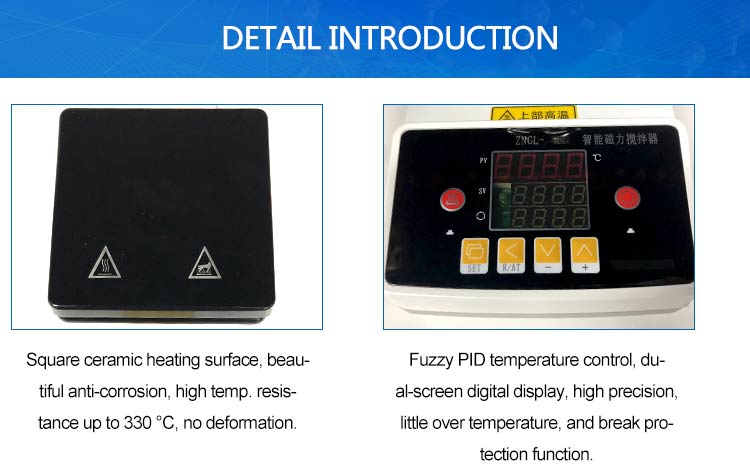

9. The magnetic stirrer adopts square ceramic, metal surface, anti-corrosion, smooth and easy to clean.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

How to use magnetic stirrer:

Fix the vertical rod in the screw hole on the upper back of the stirrer, adjust the height of the cross clamp, fix the reaction flask with a ten thousand clamp, put in a suitable stirrer, insert the power source ~ 220∨, and turn on the switch.

Adjust the "Stirring" knob clockwise, and adjust it to a suitable position for stirring as needed.

If the stirring capacity is large or viscous solution, the knob can be adjusted appropriately to increase the stirring intensity.

What are the requirements for using magnetic stirrer?

1. Ambient temperature: 0-50℃, no corrosive gas.

2. Relative humidity: 35%-85% (no condensation).

3. Do not use it with overload.

4. To ensure safe use, please ground the wire.

5. Fuse Φ5×20 15A.

6. When not in use for a long time, please store it in a dry and non-corrosive gas place.

What is the role of a magnetic stirrer?

The general magnetic stirrer has two functions of stirring and heating. Specifically: make the reactants mix uniformly and make the temperature uniform. The second function is to heat in a closed container, which needs to prevent bumping. For example, in the distillation process, you can add zeolite or use a magnetic stirrer. The third The effect is to speed up the reaction rate, or the evaporation rate, and shorten the time.

Model | ZNCL-BS |

Voltage | 220V 50\60Hz |

Stirring speed | 50-1800r/min, No polar adjust |

Heating power | 260-750W |

Temperature accuracy | ±1℃ |

Temperature control | Intelligence control. Inside, outside probe. |

Temperature range | RT~350℃ |

Boiling | Water 10-25 mins |

Furnace wire | Cr20Ni80 |

Heating palate size (mm) | 140*140 180*180 230*230 280*280 |

Material | Black crystal ceramic |

Fuse | ø5×20 15A |