Advantages of lenticular filter:

The lenticular filter is a new type of laminated filter, which can replace the diatomaceous earth filter and is used for the filtration, purification, clarification and purification of small impurities in various liquids. The structure is reasonable, there are no dead corners inside and the mirror surface is polished to ensure that there is no residual liquid and easy to clean.

Features of lenticular filter:

1. It is easy to clean, and the inlet/outlet can be equipped with a special drain valve, which is convenient for draining water.

2. It is easy to replace the filter element and reduce the leakage of the filter material.

3. The stainless steel pressure gauge can display the pressure value in the tank in real time.

4. The product is made of stainless steel, high temperature resistance, corrosion resistance, and durable.

5. The large cake filter is equipped with up to 4 filter cakes as standard, which can meet the filtering requirements of large flow.

6. Adopting bottom-in and bottom-out structure design, effectively avoid the turbulent flow of the material and liquid, and improve the filtration performance.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy life-long warranty maintenance, and we only charge the cost price of replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

1. What are the parameters of the lenticular depth filter?

Filter element material: polypropylene membrane (PP) filter element, polytetrafluoroethylene (PTFE) filter element, cellulose acetate membrane (CN-CA) filter element. Filter element accuracy: 0.1-60um (micron) Filter element length: 10" 20" 30" 40" (ie 250MM 500MM 750MM 1000mm) Filter element can withstand pressure: 0.42M.pa, support recoil. Filter element interface methods are: 222 (flat mouth type) 226 (plug-in type)

Filter parameters: inner surface; Ra0.2um

Outer surface: polishing treatment, matt treatment,

Filter capacity: 0.5T/H-25T/H

Pressure range: 0.1M.pa-0.6m.pa 1-6bar

The filter cartridges are: 1 core 3 cores 5 cores 7 cores 9 cores 11 cores 13 cores 15 cores

Filter cartridge height: 10" 20" 30" 40"

Commonly used filter element material: polytetrafluoroethylene (PTFE), polyaluminum (PE), nylon (NYLON), polypropylene (PP)

The filter pore size is: 0.1UM 0.22UM 0.45U 1UM 3UM 5UM 10UM

Material: AISI304 (1.4301) 316L (1.4404)

2. What is the working principle of the lenticular depth filter system?

Lenticular depth filter is mainly used in auxiliary services in food processing, wine making, beverage, pharmaceutical, cosmetics, and chemical industries. Lenticular depth filter has a wide range of applications. According to the filter purpose, media condition, configuration of different forms and different materials of filter elements. For example, the pharmaceutical water in a GMP factory can be used in series with two sets of 5UM and 1.0UM folded membrane cartridge filter elements. In the fermentation industry, air filtration can sterilize the incoming air, remove bacteriophage, and seal the exhaust gas for treatment to reach the HIM standard for bacteria filtration.

3. What are the application scenarios of lenticular filter?

Microbial and solid filtration of alcohol, syrup, beer.

Filtration of juices and concentrated juices.

Clarified alcohol, dissolving enzyme, liquid glue, olive oil.

Pharmaceutical, chemical, electronic filtration, etc.

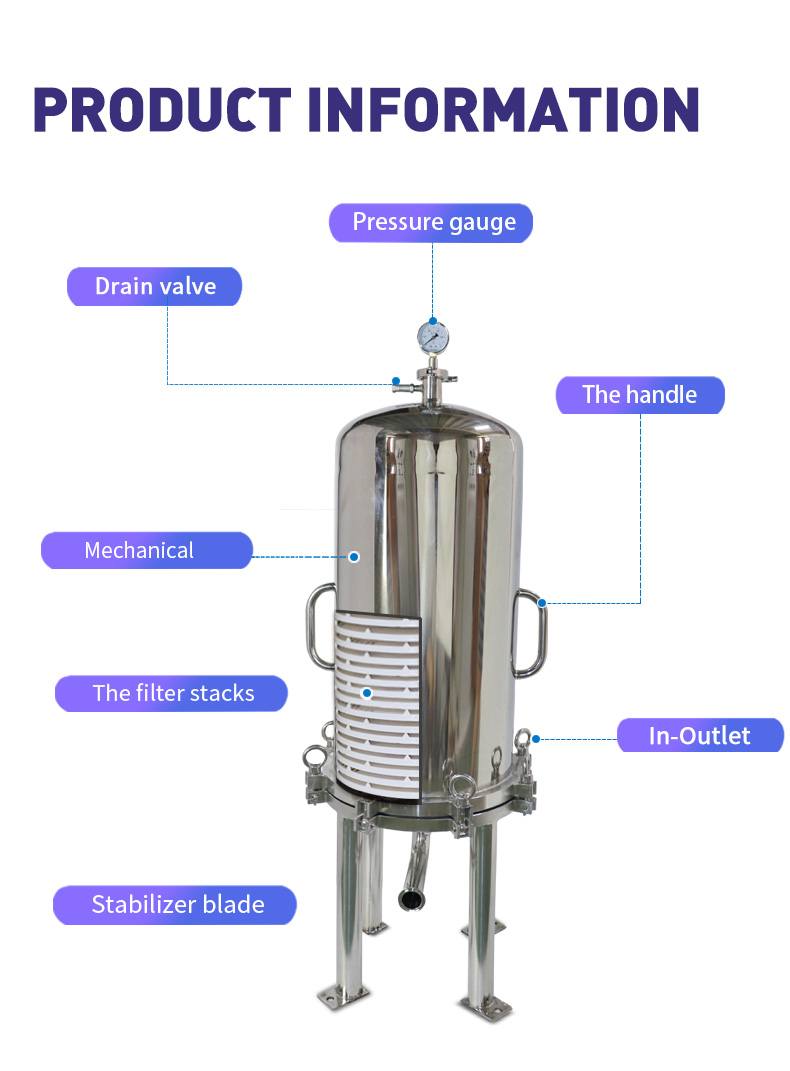

Shell:Stainless Steel 304 316L | Pressure Gauge(option):Tri-clamp |

Vent/Drain Valve:304 316L | Drain Valve(option):Tri-clamp |

Eye-bolt:Stainless Steel 304 | Finish Type:Mechanical/electrolytic polishing |

Stabilizer Blade:304 | Max Operating Pressure:0.6Mpa |

O-ring:EPDM,PTFE,Viton,Silicone | Max Operating Temperature:150℃ |

Connection of Shell:Flange | Disinfect:Online or Steam |

In-Outlet:Flange,Tri-clamp,Thread | Sterilization:121℃/30min |