Advantages of falling film evaporator:

The falling film evaporator is operated in a vacuum state, the material evaporates at low temperature, and the heating time is short, which can keep the original flavor of the material to the maximum. Continuous in and out of materials, easy to operate, maintain and clean, widely used in food, pharmaceutical, chemical, environmental protection and other fields.

Features of falling film evaporator:

1. The heating system is steam heating. The heating is uniform, the material liquid is liquid film flow evaporation, and it has the characteristics of high heat transfer efficiency and short heating time.

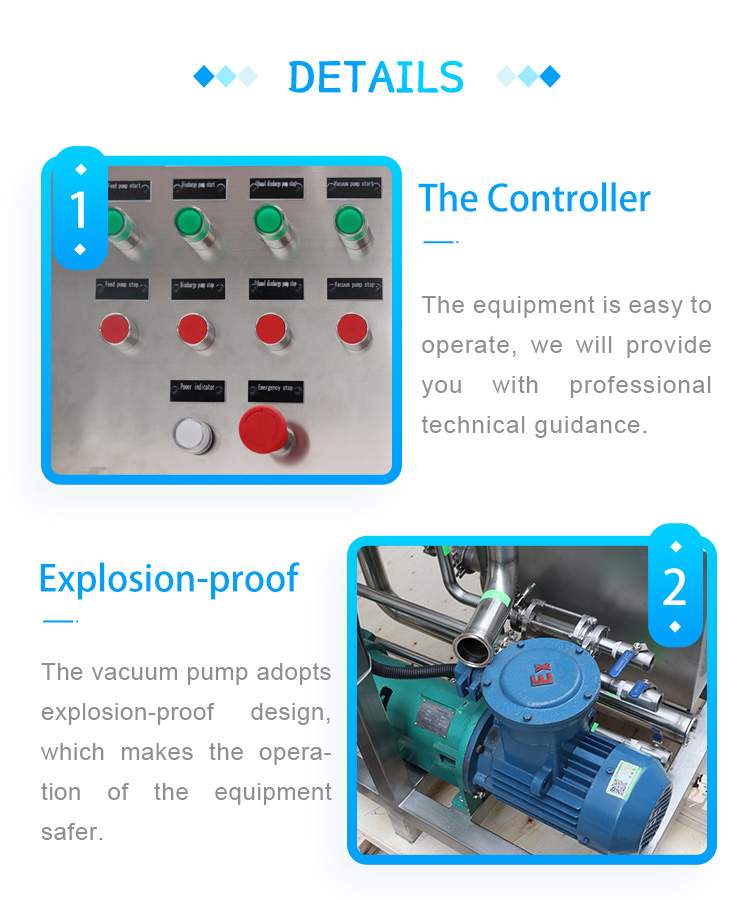

2. The equipment can be equipped with an automation system to realize automatic control of the feed volume, automatic control of heating temperature, automatic control of the discharge concentration, and automatic control of cleaning.

3. Continuous feeding and discharging, the required concentration of the material liquid can be achieved by one pass through the equipment.

4. It can be equipped with protection measures for sensitive materials in the event of sudden power outages and failures. Other automatic operation and control such as security and alarm.

5. The equipment can be equipped with cleaning pipelines, which can realize on-site cleaning. The whole set of equipment is easy to operate and has no dead ends.

6. The complete system has reasonable and beautiful design, stable operation, high efficiency and energy saving, and low steam consumption.

After-sales service:

1. Provide targeted installation videos;

2. Under the premise of correct installation, regular maintenance and use, we guarantee a one-year warranty;

3. After the expiration of the warranty period, the products sold by our company enjoy lifetime warranty repairs, and we only charge the cost price for replacing the standard parts and seals of the product;

4. The technical staff puts forward reasonable suggestions according to the use of the product, and assists the customer to choose the appropriate model;

5. Provide 24-hour technical consultation response.

FAQ:

1. What is the working principle of a falling film evaporator?

The material liquid is added from the top of the heating chamber, and after being distributed by the liquid distributor, it flows downward in a film shape under the action of gravity, vacuum induction and air flow, and is heated and vaporized in the tube. The vaporized vapor and liquid are led out from the lower end of the heating tube together. After the vapor-liquid separation, the concentrated liquid is obtained. The secondary vapor evaporated from the material liquid enters the next-effect evaporator for heating or enters the condenser.

What are the application areas of falling film evaporators?

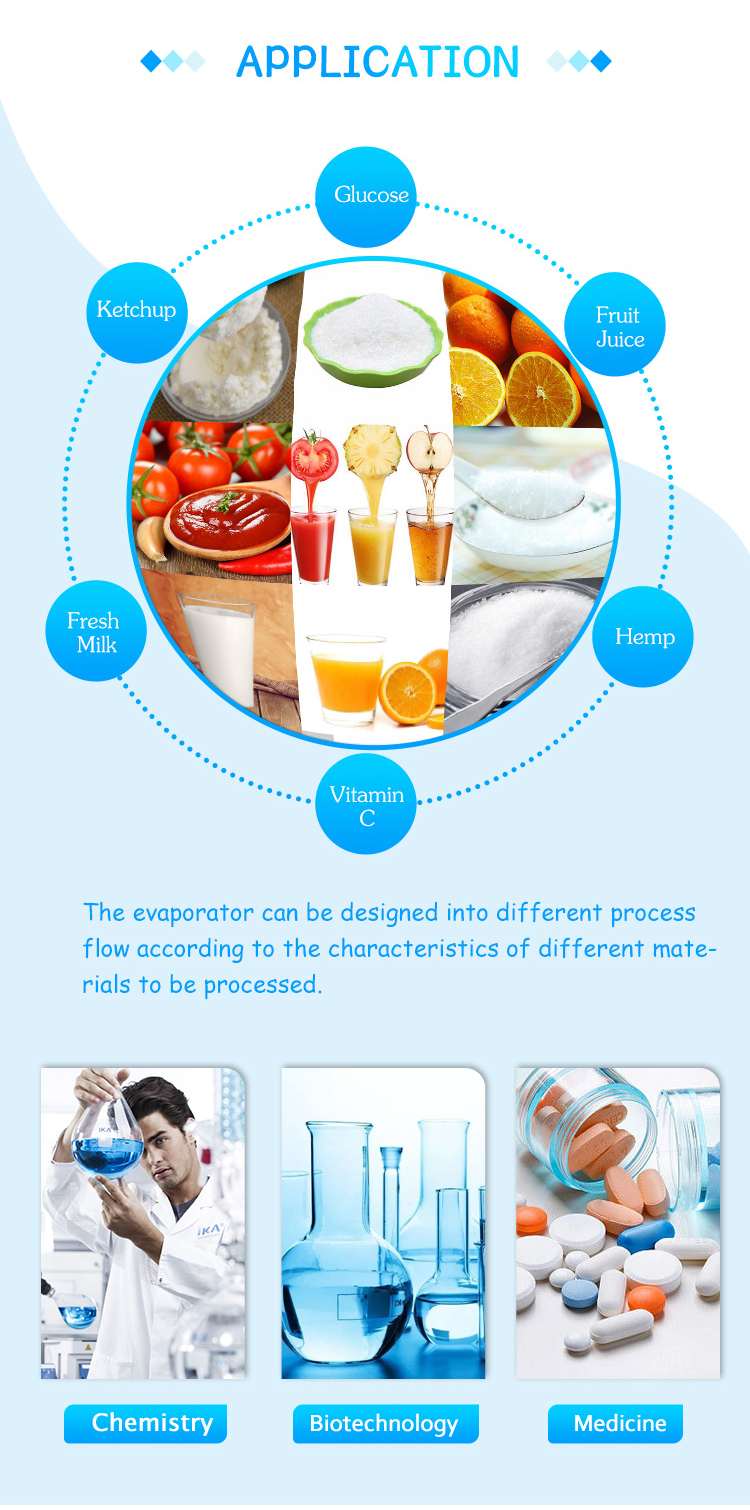

It is widely used in the concentration of aqueous solutions such as glucose, starch sugar, oligosaccharides, maltose, sorbitol, fresh milk, fruit juice, vitamin C, and maltodextrin. It can also be widely used in waste liquid treatment in industries such as monosodium glutamate, alcohol and fish meal. The falling film evaporator performs continuous operation under vacuum and low temperature conditions, and has high evaporation capacity, energy saving and consumption reduction, low operating cost, and can maintain the original color, fragrance, taste and other components of the processed material. It has been widely used in many industries such as food, medicine, grain deep processing, beverage, light industry, environmental protection, chemical industry and so on.

What is the evaporator of the falling film evaporator?

The evaporator is a tube-and-tube heat exchanger, with liquid material passing through the tube side and heating steam at the shell side. The liquid material enters from the top of the evaporator and enters the heating tube through the distributor. The liquid material flows down the heating tube and is heated to evaporate , Until the bottom of the heater, the concentrated liquid and the secondary steam produced by evaporation enter the separator for separation, and the bottom is equipped with a liquid level switch to control the water distribution.

Function: Heat and evaporate liquid materials.

Falling Film Evaporator | |

Treatment medium | CBD ethanol extract |

Design recovery capacity | 200L/h (alcohol) |

System heating source | Heated with saturated steam |

System cooling source | Using chilled water unit for circulating cooling |

System working power | 380V three-phase power, total installed power 10.15kw (380V,5O-60Hz) |

Equipment dimensions | 2.0 X2.0 X2.3 m |