Product Description:

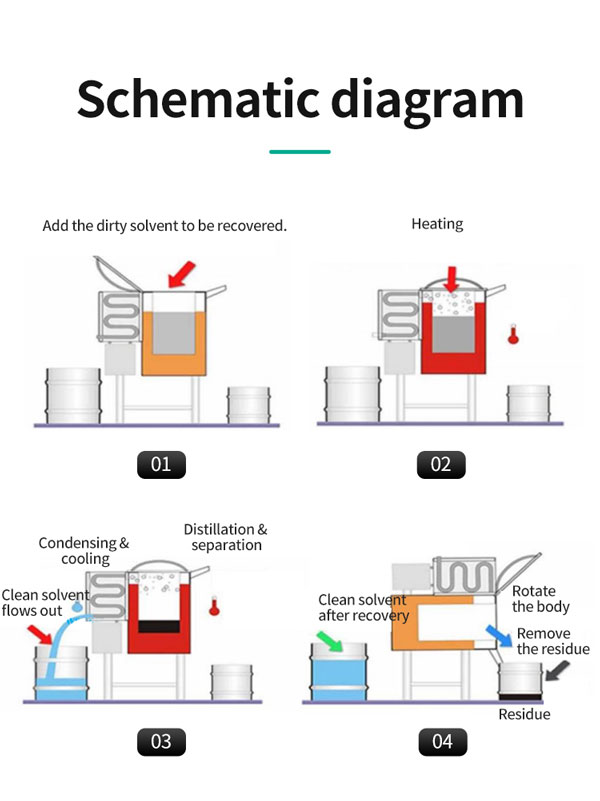

The equipment adopts the precept of dsolvent recovery machine and solvent recovery unit, and the used organic solvent is recovered and processed to regenerate and recycle the waste organic solvent. (The gear is restored to a brand new solvent and put into the production process again to realize a number of recycling of the solvent recycling machine to save heaps of prices and obtain the aim of environmentally pleasant manufacturing.)

Simple operation: no want for particular personnel to operate, employees only have to add materials, activate the power, and clean up.

The residue is enough, and the entire course of is automatically recycled and mechanically shut down; saving human sources. The quality of the solvent after recovery is pretty a lot as good as new: as a outcome of the tools adopts the principle of distillation and separation, no chemical components are added, and the chemical traits of the solvent will not be modified in the slightest.

What Is Solvent Recovery?

Industrial solvent recovery machine is the process of extracting useful solvent recycling machine from a course of waste stream. In the oil and gas trade, industrial-scale distillation is the major method for solvent recovery systems, useful chemical components, and petrochemical feedstock from hydrocarbon mixtures. For instance, extracting hydrocarbon oils from petroleum sludge in a solvent restoration unit.

By recycling helpful process inputs for reuse, solvent recovery helps operators shave off costs for procuring new solvent recovery systems/raw supplies and waste disposal. Additionally, operators can improve their operational safety and effectivity and guarantee compliance with provisions from environmental regulatory authorities such as the EPA.

Types of Solvent Recovery Systems:

A solvent restoration system is a technological answer for extracting useful solvents and uncooked materials from industrial effluents through varied strategies. When used efficiently, solvent recovery strategies can recuperate up to 80% of helpful solvent recovery unit and uncooked supplies in high-purity from course of waste. Many operators make the most of modular course of skids with semi-continuous operation for the solvent restoration course of.

Advantages of Recovery Systems :

●Reduce your solvent disposal costs and wastewater therapy surcharges.

●1 12 months or better payback on most solvent recycling items.

●Solvent recyclers sized to fulfill the needs of small users, and the biggest industrial plants.

●With new, used, and refurbished solvent recyclers, we can often find a system to fit your finances.

●Technical help with organising and coaching to use the solvent recycling techniques, parts washers, and wastewater remedy techniques we sell.

●We won’t neglect you after the sale.

Features of solvent restoration:

●Proprietary solvent restoration methodology designed for optimal efficiency

●Superior rising cyclonic evaporation expertise

●Continuous feed solvent evaporator & recovery system

●Highly durable, long lasting design

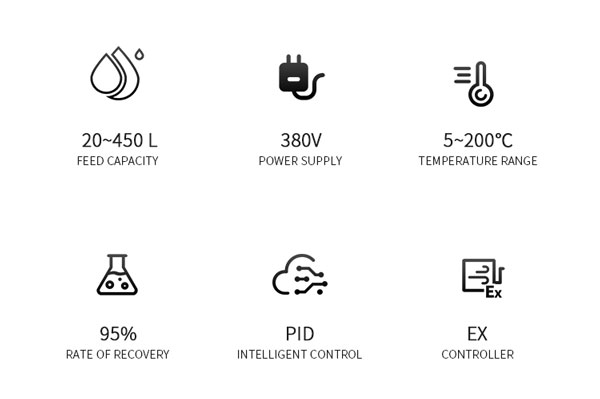

●PLC managed with pill and remote monitoring capabilities

●Full human-machine interface with touch screen

●Professional Engineer stamped and approved

●Designed, engineered and built within the china

Why to determine on FBL solvent recovery machine?

1-Savings - Quick Payback

●Eliminate 90-95% of hazardous waste supplies

●Eliminate “cradle to the grave” Waste legal responsibility

●Eliminate or cut back the need for a licensed waste hauler

●Qualify as a “cesqg” Under mdeq/epa laws

●Reduce solvent purchases by 90-95%

●Formalize waste procedures/osha-epa-mdeq

●Decrease bills

●Increase money flow

And rather more...

2-year Limited Warranty

FBL signature commitment to gross sales, set up, training & service

In today’s surroundings, customers respect the meaning of efficiency, decreased cycle time and variable cost discount. Therefore FBL Solvent Recyclers are the best choice! FBL continues to redefine what a Solvent Recycler provider should do for its customers:

●Lowers your costs

●Improves your efficiencies

●Maintains your system to supply longer life

●Provides professional expertise

The system is totally programmable by way of a separate PLC unit linked to a C1D1 accredited pill, all of which could be monitored remotely by way of a cloud connection. Remote entry to the solvent restoration system permits the operators to view and control the speed of the motors and pumps, as well as viewing and data logging the performance metrics.

Additional features of the solvent recycling machine include the option for each process water or a chiller to go well with your particular person process needs.

solvent recycling machine is pre-approved and ready for professional engineers to field verify in all 50 states, so you might get operational quicker. In partnership with PSI (Pressure Safety Inspectors), our solvent recovery system comes with a PSI technical report certification and a subject verification voucher to satisfy your state and native regulations.

Once your system is installed, simply name PSI and schedule your subject verification. Simple as that!

FBL solvent recycling machine for sale.We make the most of our design, engineering, compliance and manufacturing experience to make sure that our solvent recovery tools is dependable, high-quality, and refined. solvent recycling machinewas founded on high quality, built on service, and measured on outcomes.Contact us to get solvent recycling machine price

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) | Temperature range (℃) | Treatment time (Min.) | Recovery (%) |

SR-20Ex | 20 | 380 | 3 | 5~200 | 120 | 95 |

SR-40Ex | 40 | 380 | 4 | 5~200 | 150 | 95 |

SR-60Ex | 60 | 380 | 5 | 5~200 | 180 | 95 |

SR-80Ex | 80 | 380 | 6 | 5~200 | 210 | 95 |

SR-100Ex | 100 | 380 | 8 | 5~200 | 240 | 95 |

SR-125Ex | 125 | 380 | 8 | 5~200 | 240 | 95 |

SR-250Ex | 250 | 380 | 16 | 5~200 | 270 | 95 |

SR-450Ex | 450 | 380 | 32 | 5~200 | 270 | 95 |